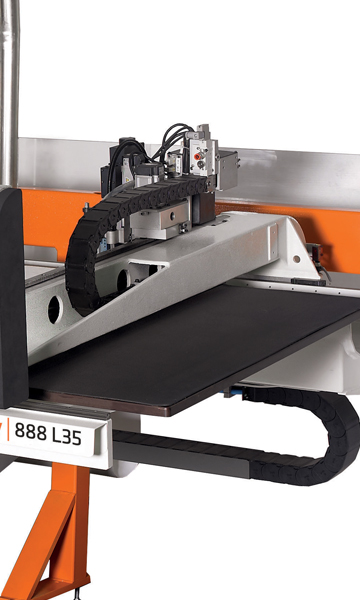

ATOM FlashCut EASY Series

The ATOM FlashCut Knife Cutting Table, EASY Series, are the ideal cnc digital cutting solutions for companies that manufacture footwear & leather goods, electronic gaskets, adhesive based materials (3M preferred Converters), foams, silicone rubbers, medical components and similar products.

Compact, solid, reliable, economic but without compromises, the FlashCut Easy series are the new standard for knife cutting tables for the future. In the 1970’s, the “classic” ATOM G222 and G888 became popular as references for swing-beam clickers and traveling head presses used in the shoe and leather goods factories all of the world. Today, thanks to over 65 years of experience and more than 250,000 cutting machines sold worldwide, ATOM presents the Knife Cutting Table FlashCut EASY, “Innovation in Tradition”.

The ease of use, compact design and the possibility to import the shapes from any CAD system make the EASY series particularly suitable for any sample departments, small-medium converting operations & laboratories that need to rapidly produce samples & prototypes or short-medium production runs.

The ATOM FlashCut EASY Series Oscillating Knife Cutting Tables share the main features of the FlashCut family:

- Five Tool or Seven Tool (Multi-Tool) Cutting Head

- Robustness of structure

- Two independent working areas (888-M25-L30 Models Only)

- Extremely Precise (Positioning Tolerance +/- 0.1mm)

- Punching speeds of 220 holes per minute

- Cutting speeds of 80 meters per minute

- Highly visible overhead LED projection system

- Smart partitioned zoned vacuum system

- High planarity of cutting surface

- Blade lubrication device

- Acquisition Systems – EASY Series can be combined with off-line acquisition systems

- Vision Systems for pre-printed material recognition

- Powerful, flexible & simple to use control software

- Automatic, interactive or mixed nesting system

- Enhanced operator safety (CE Approved)

+PLUS|Flashcut Easy

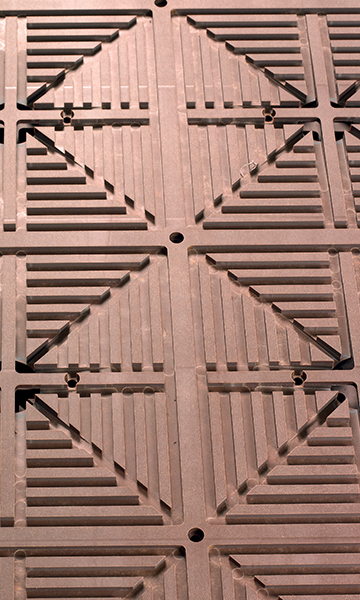

Partitioned Vacuum System

Powerful, partitioned and adjustable vacuum system. Best fixing during cutting and highest energy saving.

Performance and Reliability

Perfect quality and cutting speed, accurate mechanic engineering. State-of-the-art electronics.

Two Cutting Areas

Two working areas to collect the cut pieces on production time. Labor saving.

Two Cutting Heads

Two independent working areas to boost productivity.

Acquisition Systems

In-line and off-line leather acquisition systems. Digital pen for marking quality areas.

Optimized Nesting

Customized automatic nesting system. User friendly interface. Reduction of the process times and maximum material yield.

Applications

Solid structure and cutting precision even for fields different from footwear and leather goods.

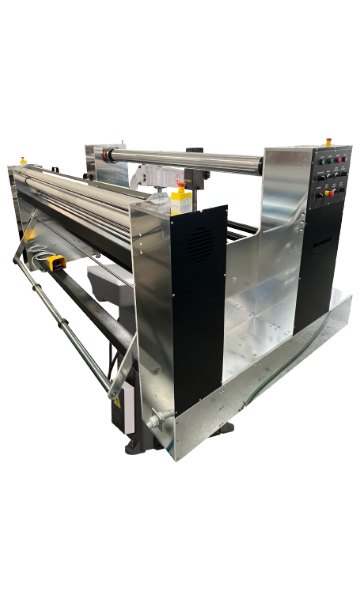

Modular Material

Handling Solutions

Standard & custom engineered material unwinds stands & winders, feeding and spreading machines, sheet-loaders, and in-line loading & off-loading tables.

Downloads

Download EASY Series Brochure

PDF - 1.10 MB

Download FlashCut

EASY 222-888 Brochure

PDF - 331 KB

Download FlashCut

EASY 888 M25 Brochure

PDF 65 KB

Download FlashCut

EASY 888 L30 Brochure

PDF - 63 KB

Download FlashCut

EASY 888 L35 Brochure

PDF - 67 KB

Download VRX Technology

Brochure

PDF 446 KB