Guidolin Girotto

Digital Laser Die Cutting Systems

The Guidolin Girotto Laser Cutting & Converting System offers innovative and cost-effective solutions for processing simple and complex geometries without the use of traditional hard tooling – superior part quality that cannot be replicated in the traditional die cutting process.

The Guidolin Girotto Laser Cutting & Converting System offers innovative and cost-effective solutions for processing simple and complex geometries without the use of traditional hard tooling – superior part quality that cannot be replicated in the traditional die cutting process. This technology increases design flexibility, is cost efficient with high quality through-put, minimizes material waste with very low maintenance.

Laser Technology is the ideal dieless cutting & converting solution for just-in-time manufacturing & short-medium runs and is well suited for converting high accuracy components from flexible materials including label stock & PSA, double sided adhesives, gaskets, plastics, textiles, difficult abrasive materials & even aggressive adhesive materials like VHB that typically adhere to the cutting blade.

Laser Cutting Technology Overview

Laser cutting is a technology that uses a laser to total cut, kiss cut and engrave materials. Laser cutting works by directing the output of a high-power laser through optics. The laser optics and CNC (computer numerical control) are used to direct the laser beam. Laser Cutting is a dieless process, meaning no hard tools are needed, and use a vector based digital image imported by the control software to direct the laser beam. The focused laser beam is directed at the material, which then vaporizes the material in the beam path leaving an edge with a high-quality surface finish & eliminating hand labor & other complex extraction methods for small piece or scrap removal.

Guidolin Girotto manufactures two popular styles of laser systems; flatbed (plotter) and galvanometer, both technologies integrated into their Flat Bed Die Cutting Press (PLAS Series – Flatbed) or Rotary Converting Platform (RO Series – Galvo).

Digital Laser Die Cutting Systems

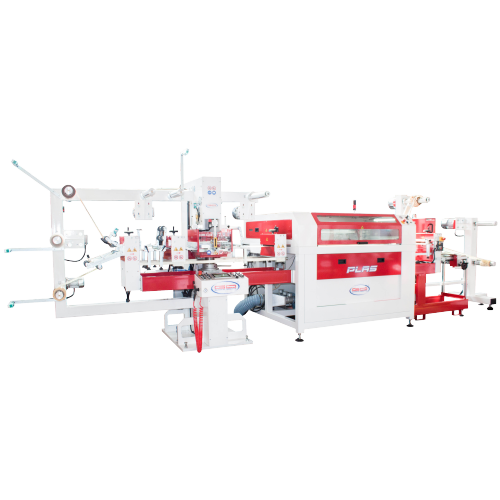

Guidolin Girotto PLAS Series

The new PLAS Series is an innovative technology which combines laser cutting strategies with flat-bed die cutting solutions. The GD PLAS has been designed to cut complex shapes with complex materials, with different thicknesses; particularly for the electronics and automotive sectors that require high flexibility. This new cutting & converting system consists of a Flat Bed Die Cutting Press, with various material handling solutions employed, coupled with an X-Y Plotter Style Laser Cutting System.

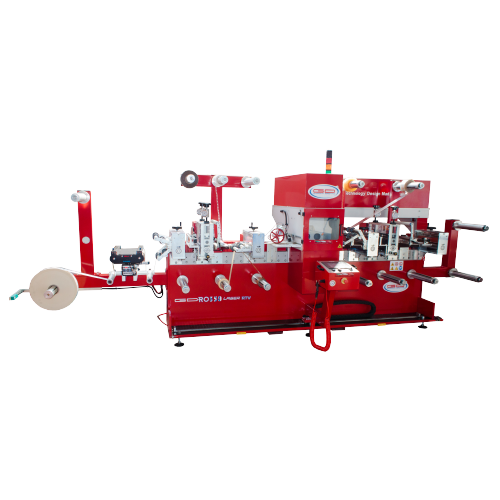

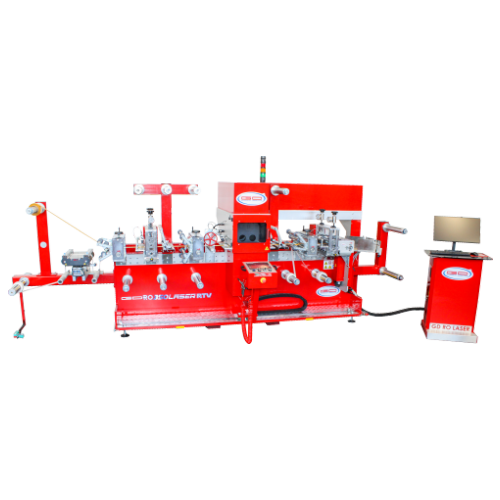

Guidolin Girotto RO Series

Guidolin Girotto’s RO Series galvanometer (galvo) laser die cutting & converting systems have revolutionized the way converters and application specialists conduct their manufacturing processes. Laser Cutting is the ideal digital (no hard tooling) cutting solution for prototypes, just-in-time manufacturing & short-medium production runs and is well suited for converting high accuracy components from flexible materials including label stock & PSA, double sided tapes, transfer tapes, foam tapes, gaskets, plastics, textiles, difficult abrasive materials & even aggressive adhesive materials like VHB that typically adhere to the cutting blade.

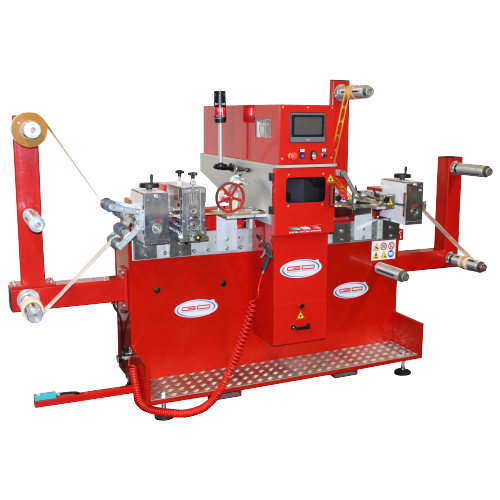

RO EL Series

The RO EL Series is a cost-effective, entry level laser die cutting solution with a 175mm wide useful working width, engineered for processing a wide variety of materials including labels, adhesive tapes, double sided adhesives, VHB, textiles, paper, foam & rubber, silicone, PU, PE, PET, polycarbonates, polyethylene, polypropylene, abrasives and similar products.

RO 250 SEries

The RO 250 model has a useful working width of 250mm and is the ideal solution for convertersthat demand versatility. This solution combines our traditional RO series rotary converting platform with the Laser Cutting module. The system interchangeability is the distinctive trademark of the Guidolin product and this unique design allows new systems to be installed on the machine without modifying the original set-up. “Multiple solutions in one machine.”

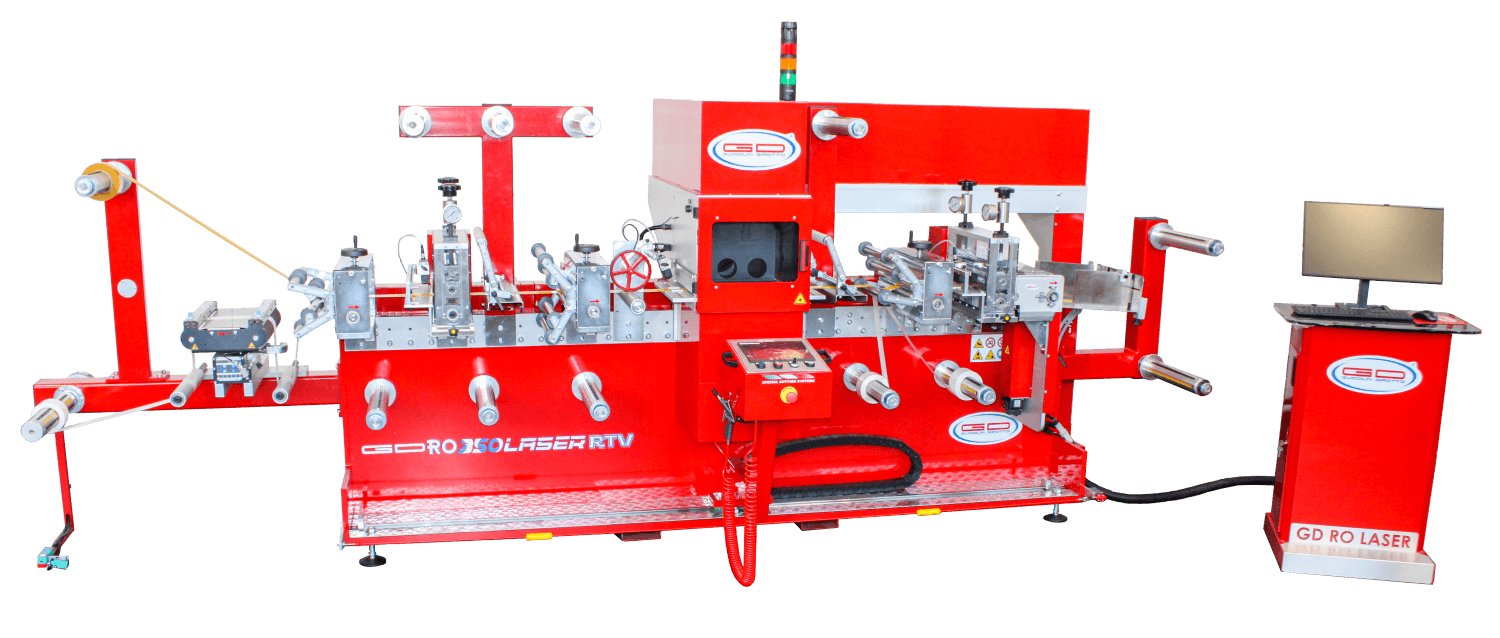

RO 350 SEries

The RO 350 series offers the most flexibility and production through-put for materials up to 350mm in width. Depending on the application, the speeds of the RO 350 can reach 100 Mts/Min and the standard 350W RF “Self-Refilling” laser source is a highly-efficient CO2 laser ideal for applications on adhesives, plastics, graphics, overlays, labels and similar materials.

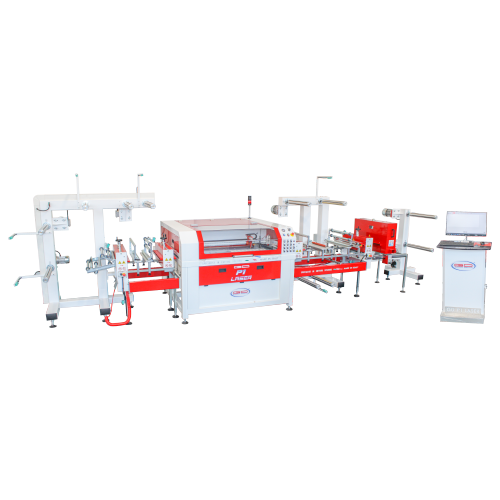

Guidolin Girotto P1 SERIES PLOTTER

The new P1 Plotter Laser Cutting System has been studied and developed for technical converting of 3M, Avery Dennison, Lohmann, NITTO and Tesa double sided adhesive materials. The machine is completely automatic and can be equipped with a variety of optional systems to laminate, change liners in different positions, kiss cutting and total cutting process, removal of external and internal waste, longitudinally kiss-slit or total slit, transversally cut to create sets, or rewind in single or multiple rolls.

Advantages of Laser Processing

Laser cutting systems are valuable processing solutions for converters and produce excellent cutting quality for adhesive based materials that are traditionally difficult to die cut. Laser systems also bring the added benefit for engraving or marking as well as cutting.

- 100% Savings in Tooling Costs – Design to Finished Part w/o Tooling

- 40% Increase in Material Yields

- 40% Reduction in Job Changeovers

- Increased Flexibility in Part Designs and Cut Geometries

- Increased Precision Levels & Edge Quality

- Depth of Cut Control – Total Cut, Kisscut & Engrave on Same Layout

- Ideal Solution for both Short and Long Runs

- Ease of Use and Increased Throughput

Today, a great deal of converting is for custom or semi-custom components. These parts need to be produced quickly, and accurately, to meet tight schedules & just-in-time manufacturing. These requests do not allow for tool design and fabrication thus making laser cutting a versatile solution for fast and flexible manufacturing.

Guidolin Girotto – Synonymous for Precision Cutting & Converting Solutions.