FEBA

LOGGERS & LOG WINDERS

The FEBA Automatic Logger / Log Winder System was developed for companies converting large quantities of adhesive and non-adhesive materials

The FEBA Automatic Logger / Log Winder System was developed for companies converting large quantities of adhesive and non-adhesive materials from the original jumbo roll down to a smaller log such as paper tapes, transfer tapes, masking tapes, filament tape, duct tape, double-sided adhesive tapes, foam tapes, protective, laminated & self-adhesive materials, polyesters, PVC, labels, graphic materials, textiles and similar products onto a paper or plastic core.

The unique revolver unit allows for a complete non-stop winding/rewinding cycle and the cores/finished log can be manually or automatically loaded/unloaded onto the shaft whilst the machine is rewinding the material onto the other shaft. This series is available as a standard machine but can be configured with a wide variety of accessories and auxiliary handling devices to meet virtually any material specification & converting requirements. Technically equipped with the latest tensioning devices to a guarantee a perfect control of the rewind tension & finished rolls with a perfectly straight end-cut & tab. In addition, the FEBA line of semi-automatic & fully automatic loggers and log winders can be engineered with lamination & de-lamination systems and equipped with log unloading & transfer systems suitable to operate in-line with FEBA Multi-Shaft Lathe Slitters.

FEBA Logger with auto double sided tab running single sided foam

Accessories

- Revolver with automatic rotation @ the end of the cycle.

- Driven or braked unwind for jumbo rolls.

- Acoustic hood with safety inter-locks for the unwind unit.

- Minimum gap unit or contact pressure lay-on-rollers.

- Automatic cut off at the end of the cycle.

- Log closure system with single sided or double sided tapes.

- Automatic tab application group for: end cycle tab, double sided tab, siliconized tab.

- Lamination & delamination group.

- Automatic core loading with in-line shaft transfer system.

- Finished log unloading & transport system to packaging line or FEBA Lathe Slitter.

- Rewinding station for silicone coated papers.

- Longitudinal slitting system & oscillating trim recovery group.

- OMRON PLC & 8” Color Touchscreen to control all machine functions- recipe driven.

Production

- Cycle time for double sided & transfer tapes 25 meters in length: 28 seconds.

- Cycle time for self-adhesive & protective polyethelene 50 meters in length: 27 seconds

- Cycle time for masking tapes 50 meters in length: 20 seconds

- Cycle time for various adhesive tapes 66 meters in length: 40 seconds

- Cycle time for various adhesive tapes 1000 meters in length: 3 minutes & 30 seconds.

Other Logger & Log Winder Machines

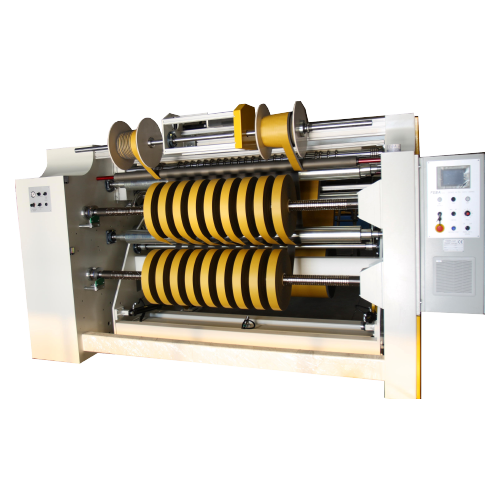

FEBA FE 95 ESPANSI

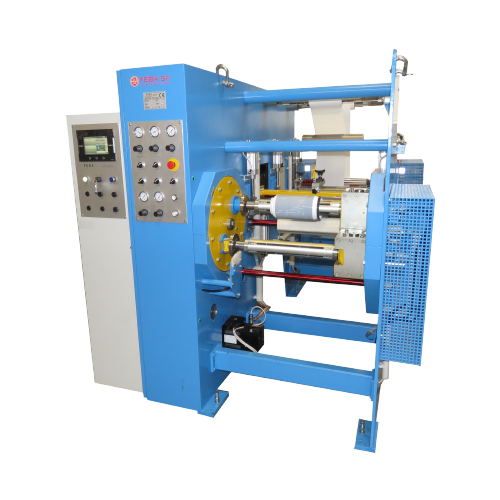

FEBA NARROW WEB LOG WINDER

(Front)

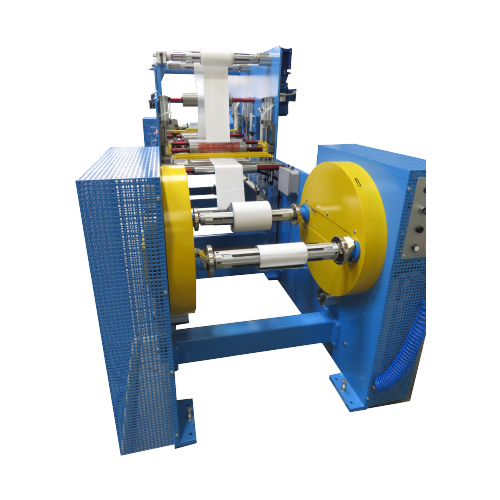

FEBA NARROW WEB LOG WINDER

(Back)