Guidolin Girotto

Rotary Die Cutting Machines

Guidolin Girotto Srl, the leading manufacturer of standard and custom engineered high speed rotary die cutting machines offers a complete range of rotary converting systems.

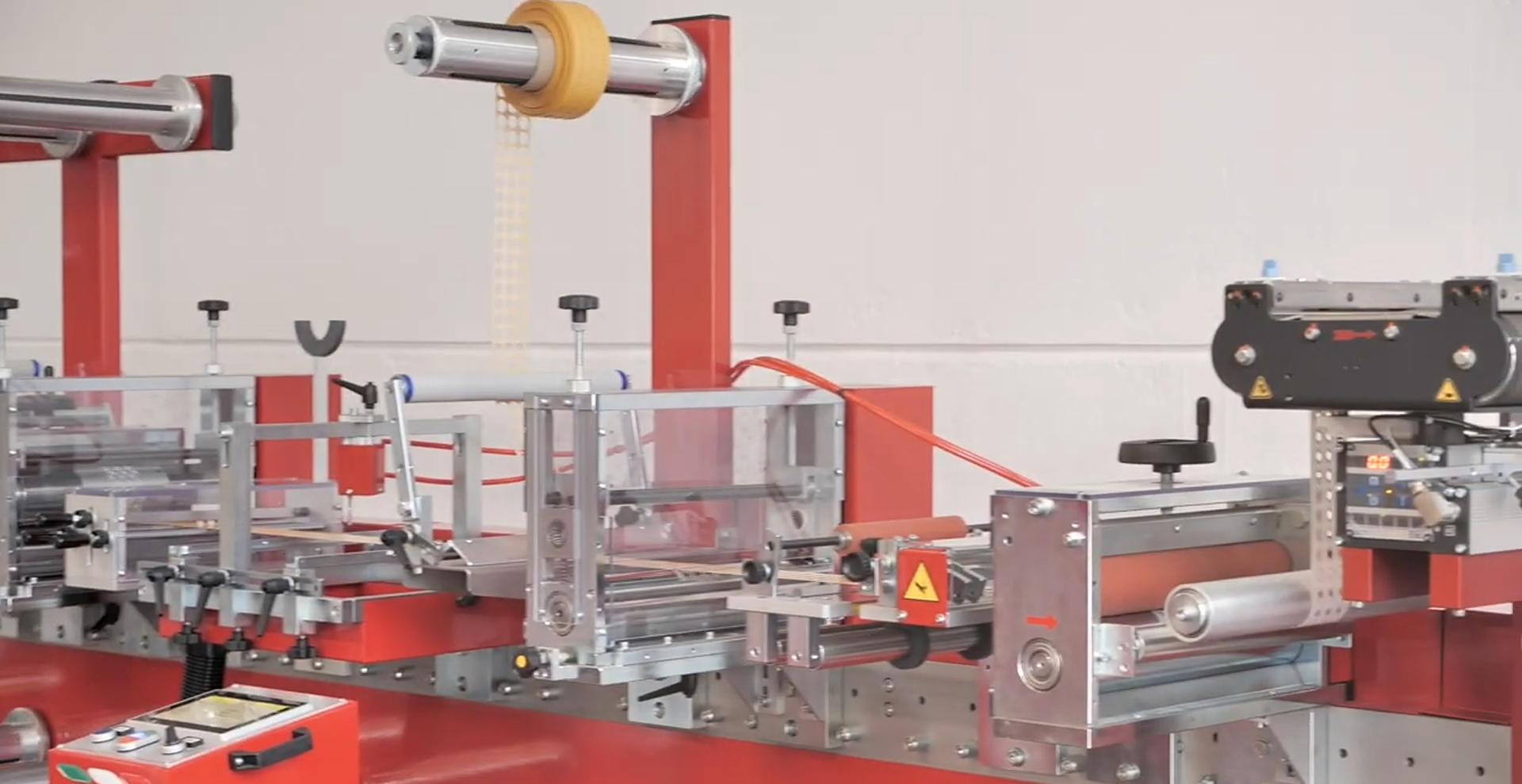

Guidolin Girotto Srl, the leading manufacturer of standard and custom engineered high speed rotary die cutting machines offers a complete range of rotary converting systems studied and developed for the die cutting & kiss cutting of technical adhesive tapes, double sided adhesive materials, foams & plastics, rubber, labels, composite materials, electronic components, felts, abrasives, cork, textiles, paper and similar materials.

The extremely solid steel frame, modular stations, numerous options and computer control system make it versatile, fast and easy to use, assuring rapid product changeover, decreasing down time and production costs. Our rotary die cutting systems are available in three working widths: 175mm, 250mm & 350mm, with body lengths of 1.2M, 1.7M, 2.2M and 3.0M, and operating speeds from 0-100 meters per minute.

Unlike most rotary die cutting machines on the market which are designed for one application, or require extensive time and labor to change from one job to the next, the Guidolin machine is engineered and designed for multiple applications offering increased versatility for different materials; simple or complex. The system interchangeability is the distinctive trademark of the Guidolin rotary converting platform and this unique design feature allows new systems to be installed on the machine without modifying the original set-up.

Our team of engineers reviews your application and requirements, listen to your needs, and respond to offer a more innovative die cutting & converting solution to improve your current manufacturing process. Each machine is designed after a careful evaluation of the customer needs, the challenges of the material to be converted, therefore every machine produced is “made to order” for each client

Modular Stations Provide Endless Versatility

- Lamination

- Liner Change Assembly

- Sheeting (Guillotine Cutting)

- Slitting

- Scoring

- Perforation

- Island Placement – Servo Driven Conveyor Group

- Pneumatic Knock-Out Stations (Start-Stop Mode)

- Stacking Units

Rotary Die Cutting Machines

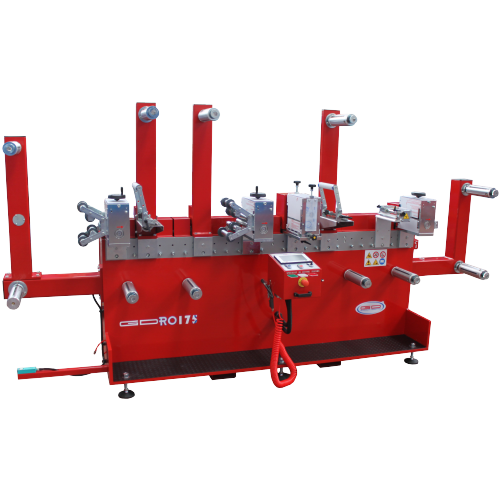

Guidolin Girotto RO 175

The Guidolin Girotto model RO 175 rotary die cutting machinery is the ideal rotary converting platform for converters of technical adhesives and double sided adhesive materials (3M, Tesa, Avery Dennison, Lohmann, Nitto, Scapa etc..), foam tapes, plastics, rubber, composite materials, felts & textiles, cork and similar products. This die cutting & kiss cutting machine has a useful working width of 175mm and is available in three body lengths; 1.7M, 2.2M and 3.0M with operating speeds from 0-100 meters per minute. The robust steel frame, modular stations with numerous configurations, and computer controlled system make the RO 175 rotary die cutter extremely flexible, fast & easy to use; guaranteeing quick changeover from job-to-job decreasing downtime, labor and overall production costs.

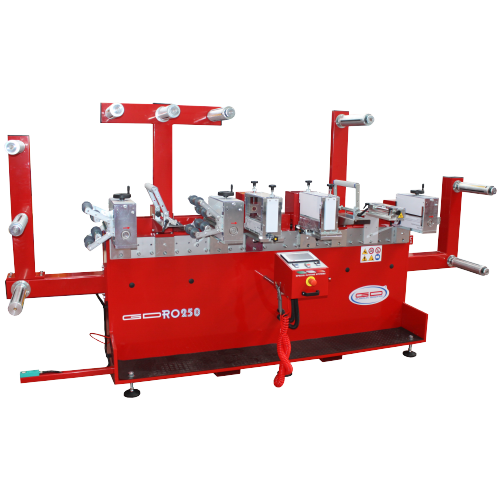

Guidolin Girotto RO 250

The Guidolin Girotto rotary die cutting system, model RO 250, is the preferred rotary converting platform by the most prominent converters of 3M, Tesa, Avery Dennison, Lohmann, Nitto Denko and Scapa double sided adhesive tapes, technical adhesive tapes, foam tapes and similar adhesive products. Guidolin Girotto is a worldwide distinction sign in the technical die cutting sector with more than 20 years’ experience in die-cutting equipment manufacturing.

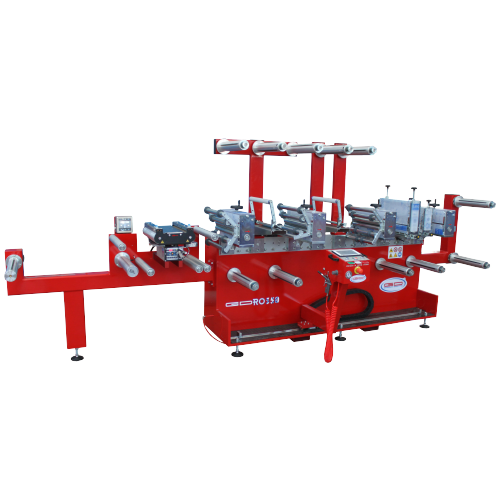

Guidolin Girotto RO 350

The Guidolin Girotto rotary converting system, model RO 350, has been designed and developed for the die cutting & kiss cutting of adhesive and double sided adhesive tapes, foam tapes and any other technical flexible material to satisfy the requirements of high production with extreme cutting precision. Its optimal field of application is represented by the following industries: automotive, aerospace, adhesive & double sided adhesive tapes, composites, electronics, medical products, felts & textiles, gaskets, packaging & plastics.

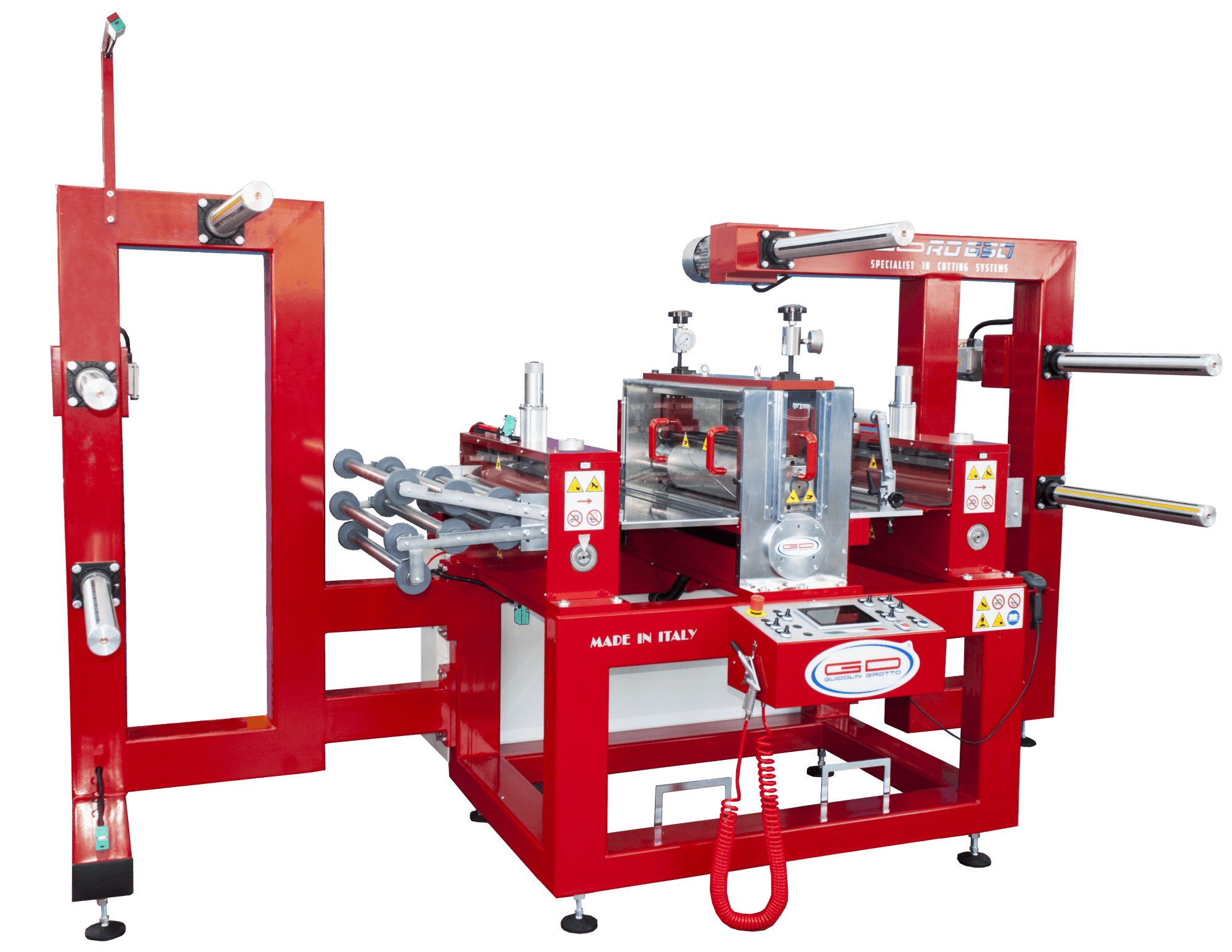

Guidolin Girotto RO 650

The GD RO 650 Rotary Kiss Cutting & Die Cutting Machine is able to process a wide range of flexible materials up to a working width of 650mm (25.5") and operating speeds from 0-60 Mts/Min. The latest Rotary Converting innovation from Guidolin Girotto significantly increases the material processing capabilities and applications available with an increase of 300mm from the traditional RO 350 model. The RO 650 standard composition includes two friction unwinds with an EMG brake + ultrasonic sensor, a central winding shaft for liner removal, laminating unit with programmable mechanical stop to adjust the gap, a servo driven die cutting station where it is possible to use tools from Z120 to Z250, scrap separator + upper rewind with precise tension control, an exit feeder roll group and two motorized rewinds on the outboard side of the machine. The easy to use 7" touch screen controller for complete control of the machine is equipped with a barcode scanner to recall the pre-programmed recipes.

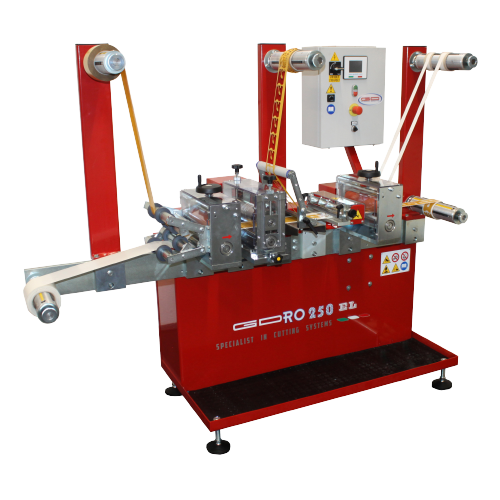

Guidolin Girotto RO 250 EL

The Guidolin Girotto rotary die cutting machine, model RO EL, is the ideal Entry Level rotary cutting press for converters of neutral and printed labels, laminated foams and textiles, adhesives & double sided adhesive materials. This compact die cutting & converting machine is available in three working widths; 175mm, 250mm and 350mm, and is capable of running at speeds from 0-60 meters per minute. The new EL version employs the same features as the traditional RO series rotary die cutting systems; rigid electro-welded steel frame, modular stations, numerous options and computer controlled system making it extremely versatile, fast & easy to use, assuring rapid changeover which in-turn decreases down time and production costs.

Wide Range of Die Cutting Capabilities

Mechanical Die Cutting

Our mechanical rotary die stations can be configured for multiple size tools, both in width and diameter, and custom stations can be designed to accept pre-existing tooling. Micrometrical adjustment both transversally and longitudinally allow for precise positioning of the tool based on web location. Reverse die cut stations are also available to cut material from the bottom – commonly used for creating a pull tab on adhesive and double sided adhesive materials.

“Flying Knife” Sheeting & Perforation

The “flying knife” servo controlled sheeting & perforation unit rotates the tool faster in order to cut in the right position. In most cases, the tool is one transversal blade and it is used as a guillotine for transversal kiss cutting, total cutting or perforated cutting. Our “flying knife” module is different than a semi-rotary die cut station because normally our rotary machines are used to cut materials thicker than label stock, laminated adhesives where the liner has been changed prior to arriving at the die-cutting station.

Servo Motor Controlled Die Cutting

The precision of registration or re-registration on each die cut is based on our control system coupled with a servo motor at each station. The die cut modules can be adjusted independently of each other, allowing the cut to be changed on the fly making precise cuts even for inconsistent fiducial registration marks. Individual servo control at each module allows for precise tension control and a different speed ratio can be set at each station – an important factor in narrow wen converting. Fiber optical photocells and sensors are used to register printed materials, printed references or pre-die cut components obtaining the required speed to register each part allowing continual feedback.

Laser Die Cutting

Laser Die Cutting offers innovative and cost-effective solutions for processing simple and complex geometries without the use of traditional hard tooling – superior part quality that cannot be replicated in the traditional die cutting process. This technology increases design flexibility, is cost efficient with high quality through-put, minimizes material waste with very low maintenance. Laser Technology is the ideal dieless cutting solution for just-in-time manufacturing & short-medium runs and is well suited for converting high accuracy components from flexible materials including label stock & PSA, double sided adhesives, gaskets, plastics, textiles, difficult abrasive materials & even aggressive adhesive materials like VHB that typically adhere to the cutting blade.

The working parameters are managed by an industrial HMI Touchscreen which can store up to 500 different jobs to guarantee quick & easy changeover. The special software, with immediate interface, grants a high feeding accuracy to reduce material waste and dramatically increase production throughput.

High structural quality, accurate die cutting precision, silence, versatility and excellent relation between quality and price are the best representation of our rotary die cutting machines in the world.