RFS Co.MEC

Platen Presses

For over 50 years, RFS Co. Mec has delivered undisputed business success in the Vigevano Italy footwear district. Production includes hydraulic presses for polishing soles and insoles, plating and printing machines for printing, plating (polishing) and cutting leather and synthetic products.

Thanks to an ever-renewed system of studies, continuous research of new materials, meticulous evaluation of the quality / price ratio and ten years of proprietary experience coupled with absolute availability responding to customer’s requests, RFS CO.MEC’s products are today known and appreciated both in Italy and throughout the world.

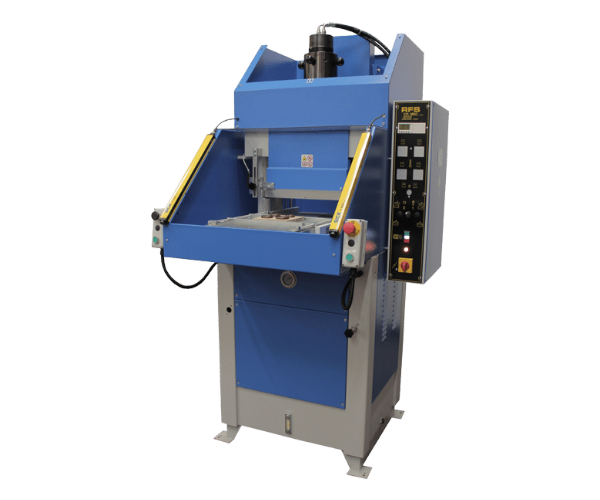

RFS CO.MEC

Plating &

Hot Stamping Presses

Hydraulic Up-Stroke Platen Presses for printing & stamping, plating, & embossing leather goods, shoe components, textiles and synthetic materials. The working cycle is completely automatic & programmable, the mechanical stop piston precisely controls the printing depth with the pressing time managed by the PLC and the automatic foil spooler controlled via encoder.

Points of Strength

- Robust mechanical design, precision machining & guiding methods guarantee press alignment and overall durability.

- Small footprint + high cutting power

- Compact self-contained hydraulic system

- Full tonnage throughout the stroke

- Adjust tonnage & maximize cycle times for each individual job

- Manual or automatic sliding work tray

- Single push-button start on automatic tray version for increased productivity

- Pneumatically adjustable die rails to support different size cutting tools

- Independent temperature controls for top & bottom heated platens

- Exterior adjustment of mechanical positive stop for quick set-up

- Photocell barrier for optimal operator safety – CE Compliant

- Minimal, low cost maintenance

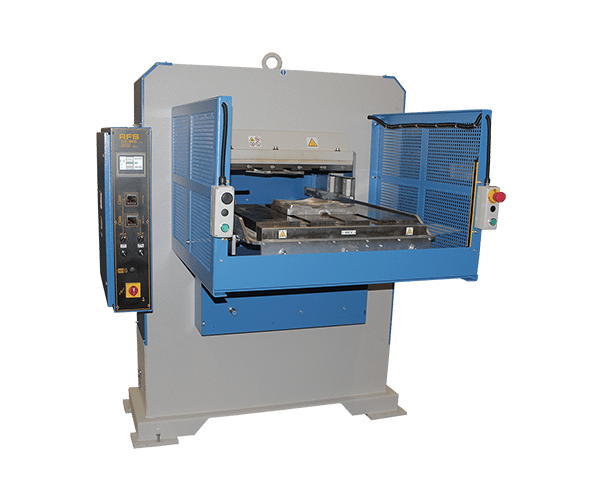

RFS CO.MEC

Die Cutting

Presses

Hydraulic Up-Stroke Heated Cutting Presses are versatile machines able to support total cutting & kiss-cutting, trimming, & crease/seal applications for a wide range of products; both natural & synthetic. Ideally suited for processing textiles & non-woven materials, foams & synthetic fibers used for insulation & sound dampening properties, vacuum formed plastics, blister packaging, pre-printed graphics, laminated materials, paper products, leather & many more.

Points of Strength

- Small footprint + high cutting power

- Compact self-contained hydraulic system

- Full tonnage throughout the stroke

- Adjust tonnage & maximize cycle times for each individual job

- Manual or automatic sliding work tray

- Dual automatic sliding work trays for increased production

- Single push-button start on automatic tray version for increased productivity

- Pneumatically adjustable die rails to support different size cutting tools

- Automatic pad shifting device for either the top or bottom platen

- Independent temperature controls for top & bottom heated platens

- Electrical heated platens with multiple heating zones

- Adjustment of cut controlled via PLC + Touchscreen Control

- Photocell barrier for optimal operator safety – CE Compliant

- Minimal, low cost maintenance

RFS CO.MEC

Thermoforming

& Vulcanizing Presses

Thermoforming Presses for EVA, polyethylene & similar materials & machines designed to vulcanize rubber and it’s by-products. The electrically heated platens provided uniform heat distribution & precise temperature control across the entire platen surface. The processing cycle is fully automatic & programmable and the degassing system allows for the expulsion of gases produced by the materials.

RFS Model B59 Series Thermoform Press

Ideal applications for a heated platen thermoform presses include various textiles, synthetic fibers or non-woven materials used for sound dampening in the transportation industry (die cut, crease/seal), compression molding for a variety of foam materials, laminating & embossing operations, filter media in multiple layers, medical inflatables, packaging closures, life preservers and similar applications. The electrically heated platens provided uniform heat distribution & precise temperature control across the entire platen surface.

RFS Model B92

Thermoform Press w/ Oven

Thermoform Press w/ Oven

The RFS model B92 is designed to thermoform rolls of polyethylene. The material is transported through the oven, then enters the hydraulic press where cold thermoforming occurs, then the material exits the machine and is cut to size. The complete line includes a clamping device to transport the material, a 570mm x 3000mm over, with upper and lower heating @ 200°Celsius, a hydraulic press with a 500mm x 450mm work area, 90 tons of working pressure complete with cooling plates.

RFS Model B82

Thermoform Press w/ Oven & Chiller

Thermoform Press w/ Oven & Chiller

The RFS model B82 is designed for thermoforming individual sheets of EVA or polyethylene. The oven is equipped with 4 drawers, 570mm W x 500mm L x 70mm H, each drawer can reach a maximum temperature of 200°Celsius and equipped with a timer to pre-set the heating time. The hydraulic press has a useful work area of 650mm x 400mm, 90 tons of working pressure, with 130mm daylight opening and cooling plates. AN off-line chiller, cooled by water, is also available depending on the application & processes associated.

RFS Rubber Mold Vulcanizing Presses

The RFS Vulcanizing Press is designed for small, medium and large rubber molds. The electrically heated platens provided uniform heat distribution & precise temperature control across the entire platen surface. The processing cycle is fully automatic & programmable and the degassing system allows for the expulsion of gases produced by the materials. With the PLC & Touchscreen control, it is possible to program 9 degasifications. When pressing rubber, a degasification system is needed to remove the air inside the rubber. With the possibility to program from 1 to 9 degasifications with different pressures, you can, as an example, set the first closing @ 50 bar, then reopen, second closing at 70 bar, then reopen, and continue this process based on the application and on the final closing will be made with the necessary programmed pressure and time to vulcanize.