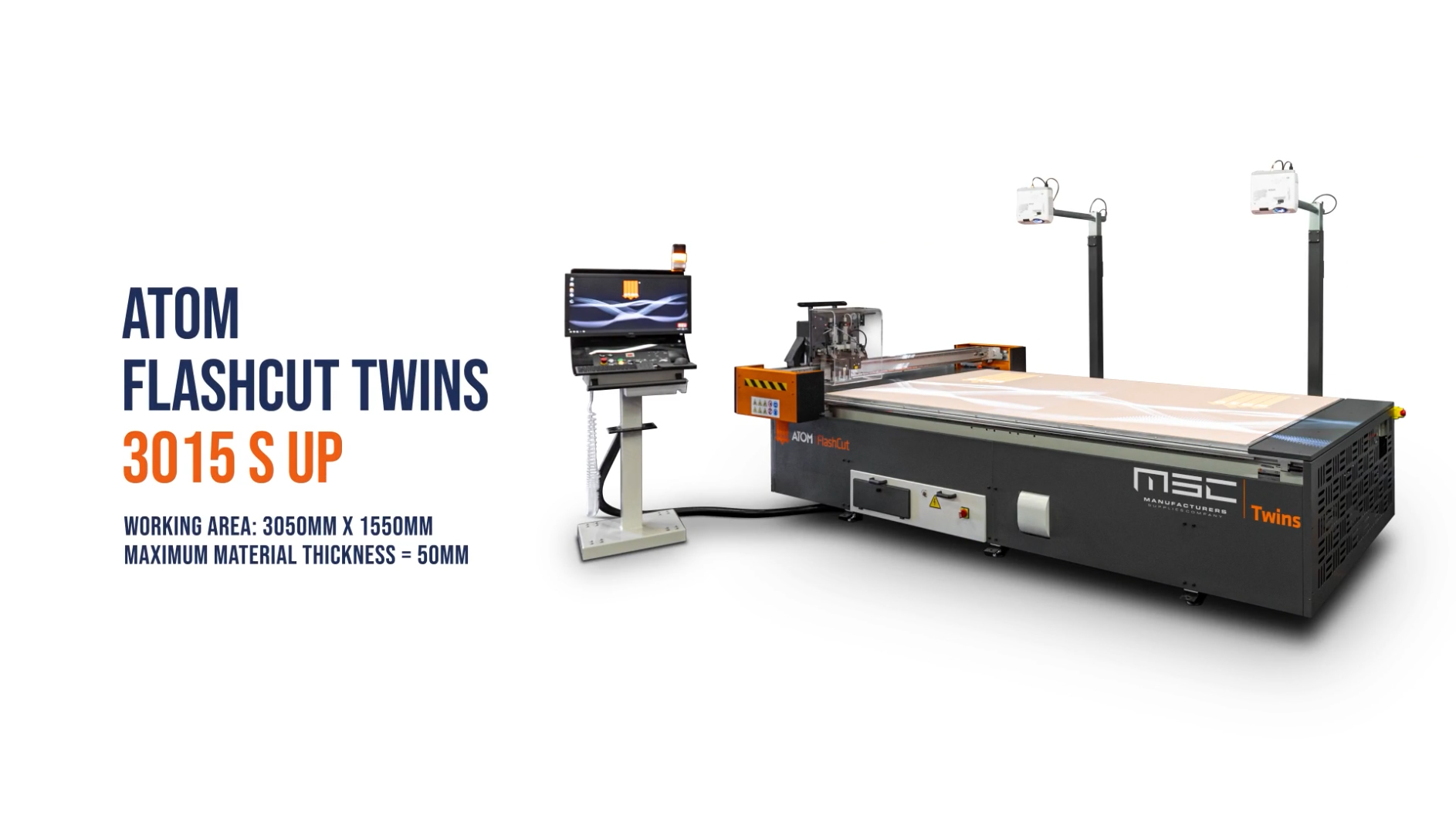

ATOM FlashCut TWINS SERIES

ATOM Digital Knife Cutting Tables & Systems, FlashCut TWINS Series, is a complete line of digital dieless cutting systems available in several configurations with either a static or conveyorized (belt feed) cutting surface capable of processing materials up to 50mm in thickness – cutting solutions for combined jobs.

Following several successful installations of the popular FLEX series, which brought us great experience in various production fields and processes, have considerably influenced the new TWINS design.

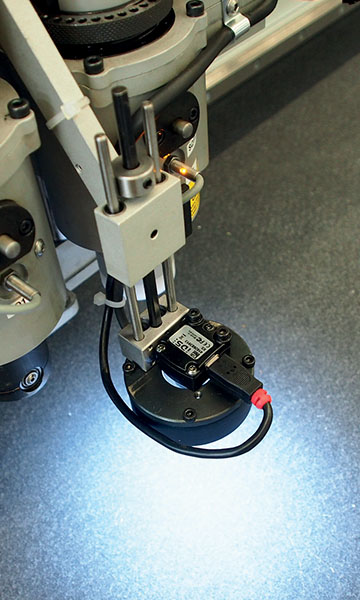

The robust structure and state-of-the-art electronics allowed us to develop a modular cutting head, with two main tools & additional optional devices including a high-resolution ink-jet printer and camera to automatically acquire the shape reference points.

The data related to the modules settings can be automatically stored and reused to quicken the tool change operations with a considerable labor cost savings & remarkable cutting quality.

ATOM’s automated cutting systems cut with extreme precision and repeatability, to within +/- 0.1mm on most materials. Advanced nesting software packages maximize yields and significantly reduce expensive material waste. Engineered and designed to cut the hardest materials like compressed non asbestos, steel inserted graphite, hard rubber, cross-linked PE foams, Kevlar & carbon fiber, plastics, and many more. Materials widely used in the automotive, aerospace, composite, electronics, medical, petro-chemical, & packaging industries. Since ATOM develops its technology in close collaboration with its clients, today it is able to offer the most advanced and most applicable cutting solution on the market – the new FlashCut ‘TWINS’.

New! FlashCut TWINS 3015 S

+PLUS|Flashcut Twins

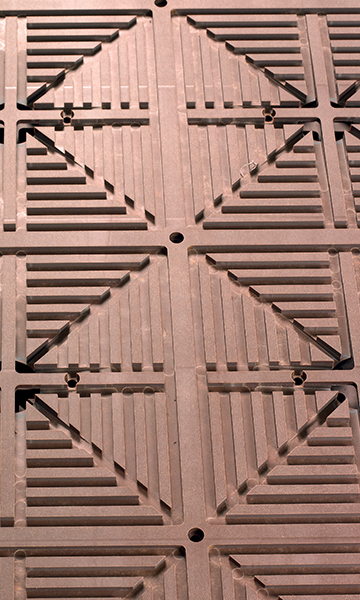

Partitioned Vacuum System

Powerful partitioned and adjustable vacuum system. Best material fixing during cutting with highest energy saving.

Long Life Projectors

Optimal vision thanks to LED lamps. Low maintenance and long life.

Reference Points Acquisition Through Camera

Digital camera equipped with LED illuminator that allows to accurately place the shapes and the cutting layout with reference to the images printed on material.

Optimized Nesting

Customized automatic nesting system. User friendly interface. Reduction of the process times and maximum material yield.

Feeding Systems

Optional tools as loading tables and take-off tables, self-centering cradle unwinding systems, with expanding shaft or multiple rolls, automatic spreaders, really helpful when cutting textile in multiple layers.

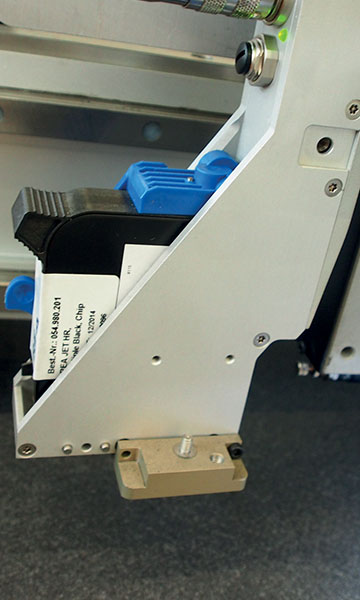

Inkjet Printer

A high resolution inkjet printer is available. The use of cartridges cut maintenance costs and allows to quickly change both colors and ink type.

Static or Conveyorized Feeding Belt Cutting Surface

On the conveyorised models, the material feeding is carried out by the combined action of the belt and a pincer mounted on the gantry.

Modular Material

Handling Solutions

Standard & custom engineered material unwinds stands & winders, feeding and spreading machines, sheet-loaders, and in-line loading & off-loading tables.

Downloads

Download TWINS Series Brochure

PDF - 242 KB

Download Oil and Gaskets Sectors

PDF - 654 KB