ATOM FlashCut

Twins EMH Series

The ATOM Flashcut TWINS EMH (Electric Milling Head) Series CNC Knife Cutting & Milling Systems allows to sequentially or separately using the cutting knife & the router.

The double Z-Axis head provides independent penetration control of both tools which allows the working of 3D shapes of any density foams (Expanded PE, PU etc.) or very hard materials like rubber, plastics, wood, composites even light alloys with extreme accuracy. In order to mill a wider range of materials, ATOM designed a new head, equipped with either a 1kW or 2.4kW electric router spindle, with variable speed turning from 1,000-40,000 RPM. An integrated air cooling system allows the mill to operate 24 hours per day. The working area is kept perfectly cleaned with its own internal dust extraction system.

Advanced nesting software packages maximize yields and significantly reduce expensive material waste. Engineered and designed to cut the hardest materials like compressed non asbestos, steel inserted graphite, hard rubber, cross-linked PE foams, Kevlar & carbon fiber, plastics, and many more. Materials widely used in the automotive, aerospace, composite, electronics, medical, petro-chemical, & packaging industries.

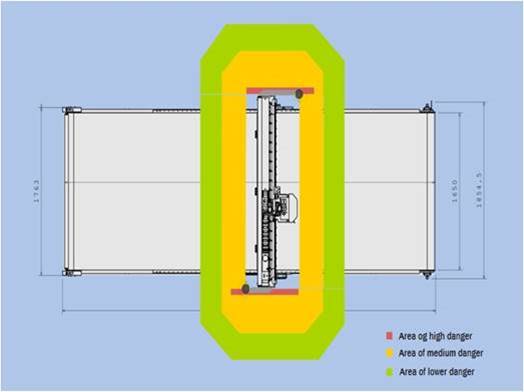

The new safety device, standard on all TWINS EMH series, is designed with two laser scanning units positioned at both ends of the moveable gantry. The laser ray covers the area around the cutting head and the dimensions of these areas of intervention can be defined accordingly.

The green area is considered “low danger” and when entered, the machine slows down the operating speed and returns to normal condition once the operator exits this area. The orange area is considered “medium danger” and when the operator enters this area, the machine will be placed in a “hold” position until the operator exits this area. The red area, closest to the moving beam, is considered “high danger” therefore once the operator enters this area the machine stops completely and cuts the main power to the motor (similar to an emergency stop button).

The ATOM Flashcut TWINS EMH Series is available in several configurations with either a static or conveyorized (belt feed) cutting surface capable of processing materials up to 50mm in thickness – cutting solutions for combined jobs.

FlashCut TWINS EMHD

The ATOM FlashCut EMHD 2Z Axis Digital CNC Knife Cutting & Milling Center was studied and developed for companies that produce case inserts, packaging components and sound dampening materials made from soft, rigid and convoluted foams with a maximum thickness of 130mm. The double Z-Axis head provides independent penetration control of both tools which allows the working of 3D shapes of any density foams (Expanded PE, PU etc.) or very hard materials like rubber, plastics, wood, composites even light alloys with extreme accuracy.

Points of Strength

- Oscillating Knife Cutting up to 130mm in Material Thickness

- Robustness of Structure

- Variable Power of Vacuum Pump (2ea. 11 kW Vacuum Pumps Standard)

- Smart Partitioned Zoned Vacuum Sectors

- High Flatness of Working Surface

- Cutting & Milling up to 110mm in Thickness

- Dust Extraction with Piped External Vacuum System

- Powerful 3 Kw Milling Head w. Internal Liquid Cooling

- Fully Automatic Mill-Tool Changing Device (20 Station)

Downloads

Download TWINS EMHD Brochure

PDF - 384 KB

Range - Models

The EMH Series is available in both a Static (S) or Belt (B) configuration - except 6115, which is only available as a Static (S) table.

Twins 1515

Working Area (MM)

1550x1550

Max Absorption (KW)

1 Pump / 2 Pump

13,46 / -

Description

Compact and powerful. Designed for those who want to get the best performance with the minimum amount of space.

Twins EMH 1515 Floorplan

Twins 3015

Working Area (MM)

3050x1550

Max Absorption (KW)

1 Pump / 2 Pump

13,46 / 23,86

Description

The most classic and best-selling version. The best size for most applications.

Twins EMH 3015 Floorplan

Twins 3020

Working Area (MM)

3050x2050

Max Absorption (KW)

1 Pump / 2 Pump

13,46 / 23,86

Description

Wider model for specific applications. The solution designed for the new material sizes.

Twins EMH 3020 Floorplan

Twins 3026

Working Area (MM)

3050x2600

Max Absorption (KW)

1 Pump / 2 Pump

13,46 / 23,86

Description

Ideal for cutting materials of significant sizes. Combined with on-line or off-line scanning systems it is ideal for full hides.

Twins EMH 3026 Floorplan

Twins 4015

Working Area (MM)

4050x1550

Max Absorption (KW)

1 Pump / 2 Pump

13,46 / 23,86

Description

Greater length to optimize the cutting of 2-meter sheets or to add a second cutting head.

Twins EMH 4015 Floorplan

Twins 4020

Working Area (MM)

4050x2050

Max Absorption (KW)

1 Pump / 2 Pump

13,46 / 23,86

Description

Ideal system for processing bovine leather and splits, particularly in the furniture sector.

Twins EMH 4020 Floorplan

Twins 6115

Working Area (MM)

6100x1550

Max Absorption (KW)

1 Pump / 2 Pump

- /23,86

Description

The maximum useful area of this range. Ideal solution for double cutting heads.

Twins EMH 6115 Floorplan

Modular Heads

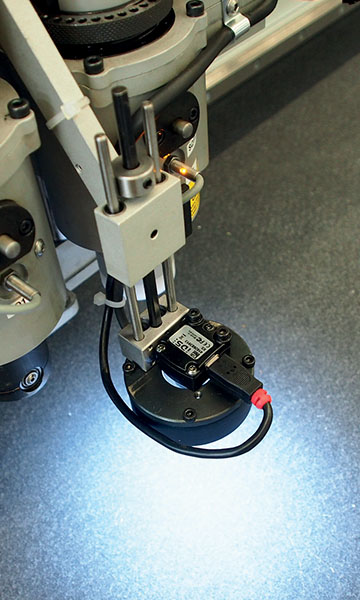

Twins Tool Head

This modular head with 2 independent vertical axes slots allows to work sequentially, matching a wide range of cutting, creasing, marking and punching tools. It is possible to perform different jobs using the most suitable tool for every specific need on the same shape. In the same cutting session it is also possible to use the inkjet printer and the camera to acquire the cutting reference points.

Twins EMH Tool Head

The EMH head allows to sequentially or separately use the cutting knife and the router. It is the best solution to combine the process of foam or rigid materials as well as to process a great number of other materials with a single tool. Two different types of routers are available: both turning at high-speed, with a power of 1 or 2.4 kW, air cooling system, variation of the speed rate during the processing and vacuum cleaning system with electric height regulation

Twins Tool Head

This modular head with 2 independent vertical axes slots allows to work sequentially, matching a wide range of cutting, creasing, marking and punching tools. It is possible to perform different jobs using the most suitable tool for every specific need on the same shape. In the same cutting session it is also possible to use the inkjet printer and the camera to acquire the cutting reference points.

Twins EMH Tool Head

The EMH head allows to sequentially or separately use the cutting knife and the router. It is the best solution to combine the process of foam or rigid materials as well as to process a great number of other materials with a single tool. Two different types of routers are available: both turning at high-speed, with a power of 1 or 2.4 kW, air cooling system, variation of the speed rate during the processing and vacuum cleaning system with electric height regulation

Tooling Combinations

The Pneumatic Oscillating Chuck (POC) – (1.0mm), is an air driven tool engineered for cutting the most difficult materials but is also used for cutting thick, soft substrates as well.

The Pneumatic Oscillating Chuck (POC) – (1.5mm), is an air driven tool engineered for cutting the most difficult materials but is also used for cutting thick, soft substrates as well.

The Drag Knife Chuck (DKC) is ideal for total cutting rigid materials like thin compressed non-asbestos, laminates & plastics up to 6mm (1/4”) in thickness.

The Electric Oscillating Knife Chuck (EOK), is ideal for cutting softer, low-medium density materials like thin foams, soft rubber, pure graphite, leather, laminates, adhesives and similar products.

The pneumatic milling chuck, or PMC, was designed for companies that want the flexibility for light-duty milling applications for rigid materials, primarily plastics (ABS, UHMW, PP, PE etc..), that are not capable of being cut with the traditional pneumatic oscillating knife chuck.

The Powered Rotary Chuck (PRC), is designed for cutting difficult fibrous materials, both uni-lateral & bi-lateral weaves, at a high rate of speed. The PRC is suitable for processing carbon fibers, Kevlar, fiber-glass, aramid and technical textiles & composites in general.

The creaser chuck is ideal for processing a wide range of single, double & triple wall corrugated cardboard. This chuck accommodates creaser wheels with a diameter of 40mm, 70mm and 95mm.

The Ultrasonic Knife Chuck is ideal for high durometer rubbers and some plastics at high speeds in a single pass.

Material Handling Solutions

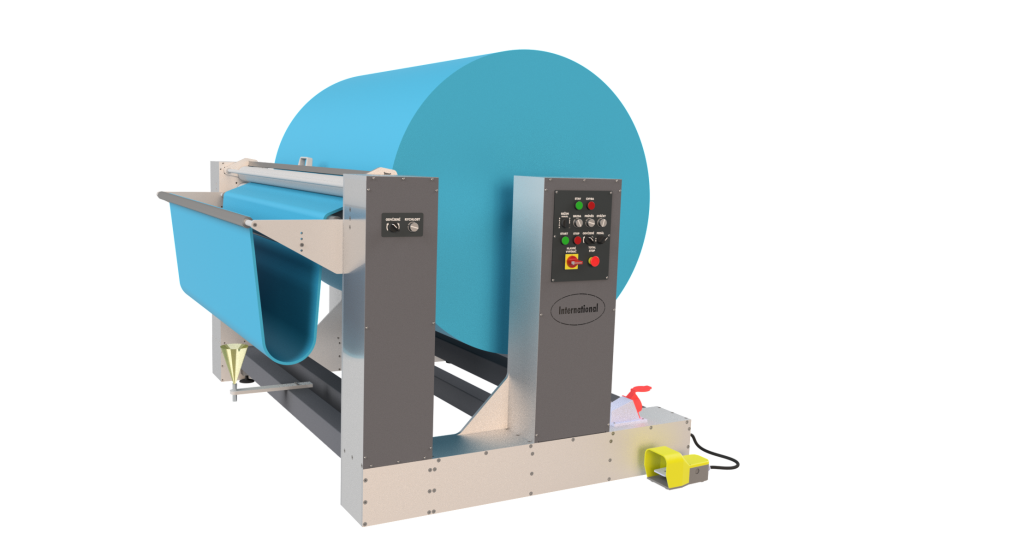

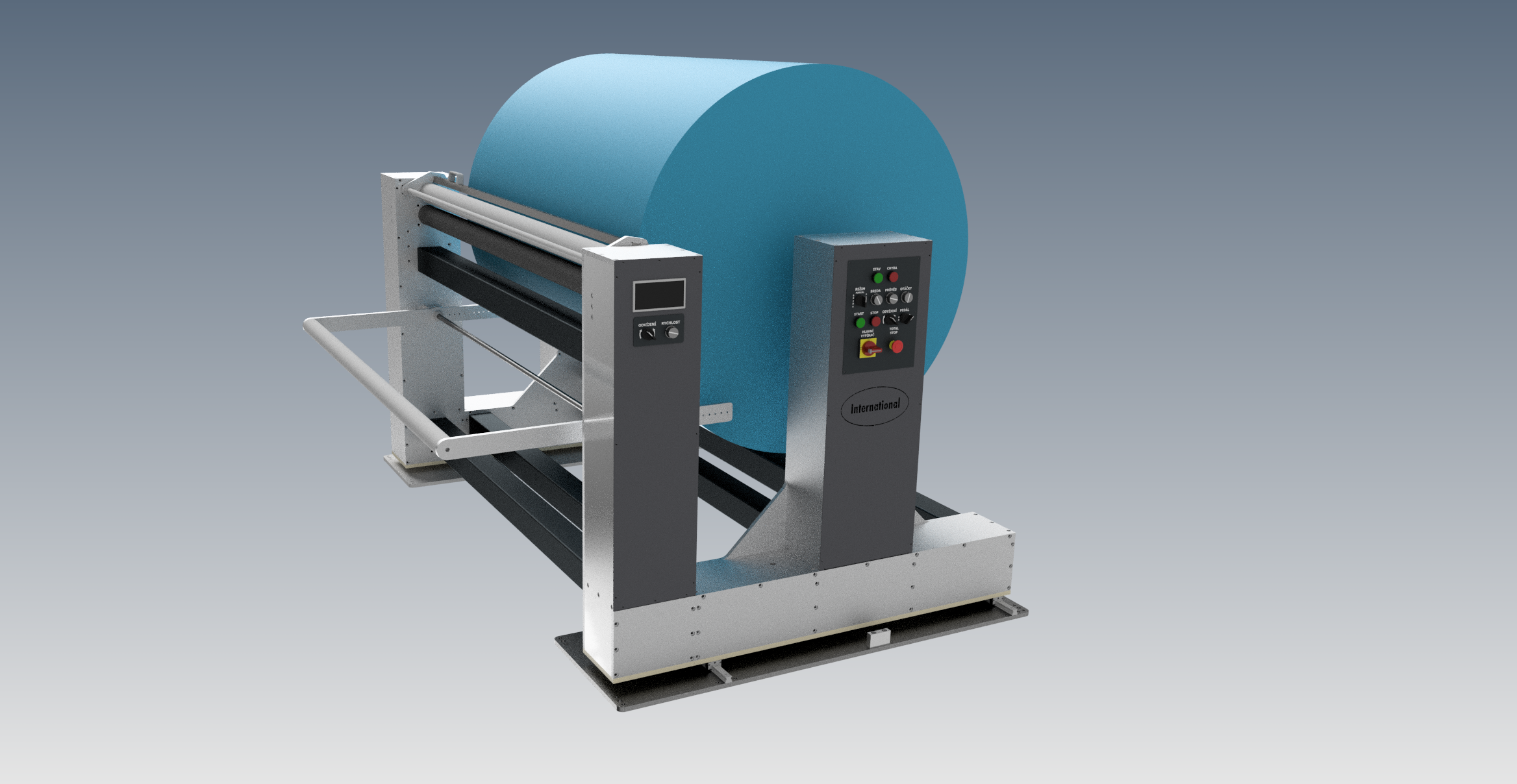

International Unwinders-Rewinders

PDF - 720 KB

The machine is equipped with:

Dancer: A sensor for monitoring material sag, controlling the drive shaft based on its data. Winding with sag allows for reduced stretching during material uptake

The machine is equipped with:

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Sensor: Monitors material sag, adjusting winding speed accordingly

The machine is equipped with:

Dancer: A sensor for monitoring material sag, facilitating reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Side Control: A device for aligning winding; it adjusts the position lightly if the material is unwound off-center.

The machine is equipped with:

Dancer: A sensor for monitoring material sag, optimizing drive shaft control for reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder

The machine is equipped with:

Dancer: For sag monitoring and optimized drive puller, ensuring reduced material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: Ensures precise winding alignment, adjusting position if material is unwound off-center.

The machine is equipped with:

Dancer: For sag monitoring and optimized drive shaft control, minimizing material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: For accurate winding alignment, making slight adjustments if material is unwound off-center

The machine is equipped with:

Loader: A device for enhanced material handling, automatically raised by the machine for improved efficiency.

Puller: Assists the drive during winding

The machine is equipped with:

Holder: A device for shaft retention, with a maximum capacity of 4 units.

+PLUS|Flashcut Twins

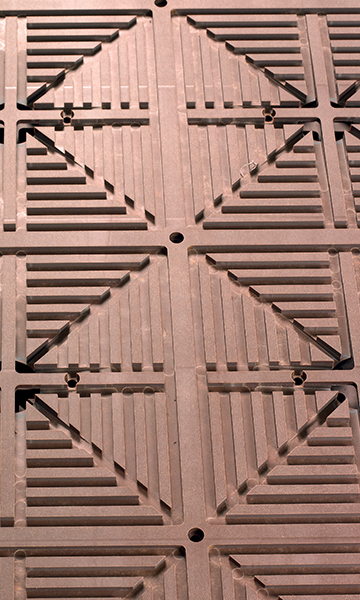

Partitioned Vacuum System

Powerful partitioned and adjustable vacuum system. Best material fixing during cutting with highest energy saving.

Long Life Projectors

Optimal vision thanks to LED lamps. Low maintenance and long life.

Reference Points Acquisition Through Camera

Digital camera equipped with LED illuminator that allows to accurately place the shapes and the cutting layout with reference to the images printed on material.

Optimized Nesting

Customized automatic nesting system. User friendly interface. Reduction of the process times and maximum material yield.

Feeding Systems

Optional tools as loading tables and take-off tables, self-centering cradle unwinding systems, with expanding shaft or multiple rolls, automatic spreaders, really helpful when cutting textile in multiple layers.

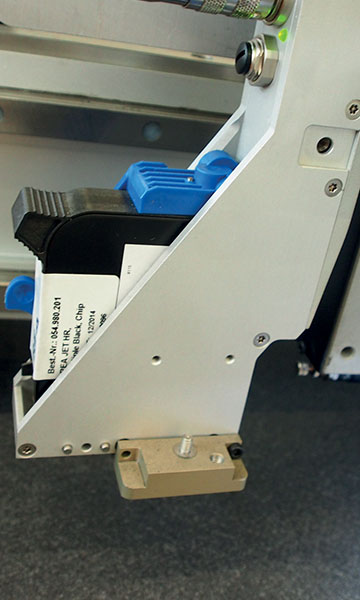

Inkjet Printer

A high resolution inkjet printer is available. The use of cartridges cut maintenance costs and allows to quickly change both colors and ink type.

Static or Conveyorized Feeding Belt Cutting Surface

On the conveyorised models, the material feeding is carried out by the combined action of the belt and a pincer mounted on the gantry.

Modular Material

Handling Solutions

Standard & custom engineered material unwinds stands & winders, feeding and spreading machines, sheet-loaders, and in-line loading & off-loading tables.