International

Laminators

Machines designed for lamination using heat-activated or cold adhesive materials up to a thickness of 100 mm and widths of 1300, 1600, and 2300 mm. The machines are equipped with longitudinal and transverse cutting units (Cross cut) as well as internal unwinders and winders.

International Laminators

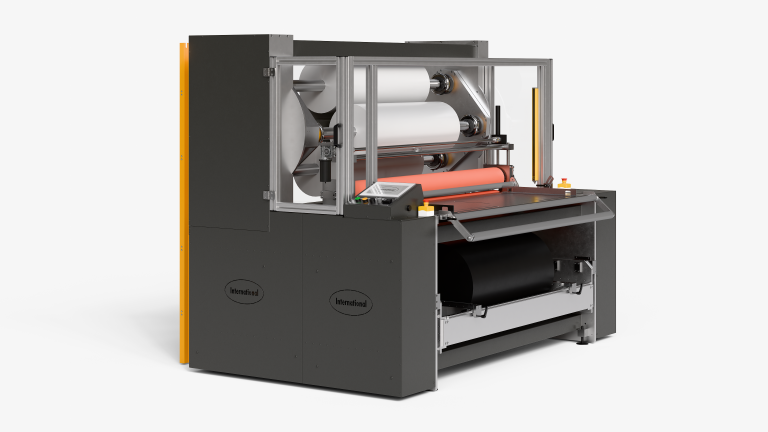

ICZ 4H Laminator

Machines designed for lamination using heat-activated or cold adhesive materials up to a thickness of 100 mm and widths of 1300, 1600, and 2300 mm. The machines serve for laminating, rewinding, and cutting materials. Each operation can be performed separately or together. The machine is equipped with a foot switch that facilitates work on the machine. The maximum processing speed of the material is 20 m/min. Machines are designed with the highest regard for operator safety, and all hazardous parts are covered during operation. The machines are manufactured with a modular structure and can be adjusted based on requirements of the customer.

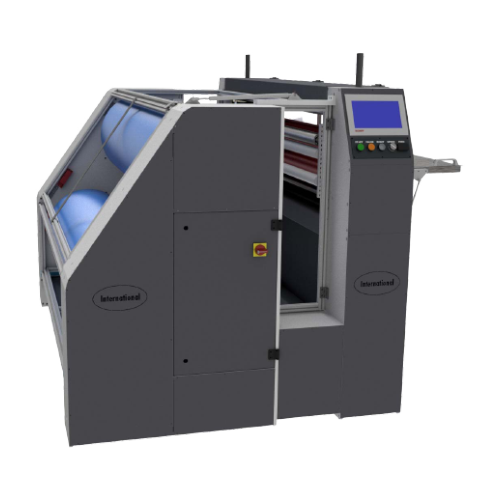

ICZ 5H Laminator

Machines designed for lamination using heat-activated or cold adhesive materials up to a thickness of 100 mm and widths of 1300, 1600, and 2300 mm. The machines serve for laminating, rewinding, and cutting materials with the option to wind a protective adhesive layer before lamination. Each operation can be performed separately or together. The machine is equipped with a foot switch, which facilitates work on the machine. The maximum processing speed of the material is 20 m/min. The machine is designed with the highest regard for operator safety, and all hazardous parts are covered during operation. The machines are manufactured with a modular structure and can be adjusted based on requirements of the customer.

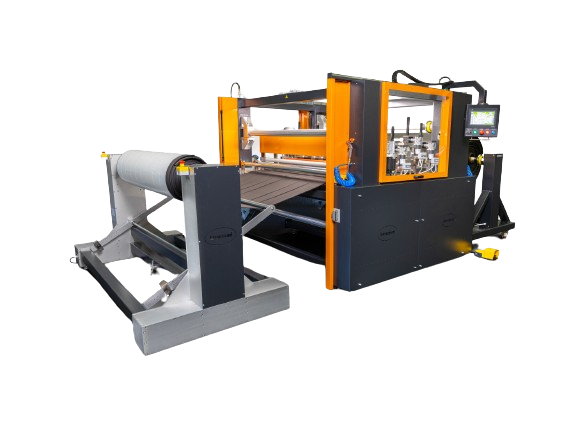

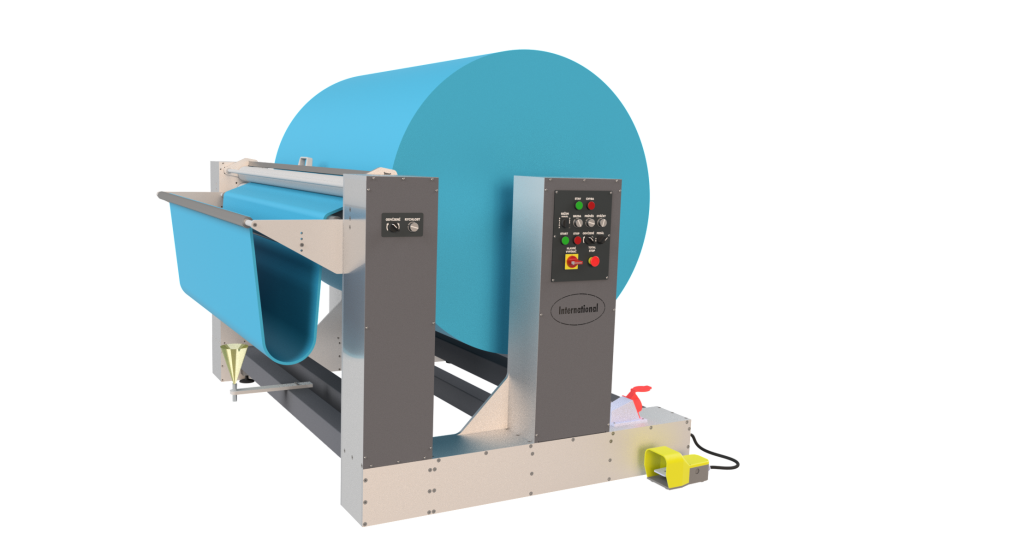

ICZ PK Laminator

Machines designed for simple lamination using heat-activated or cold adhesive materials up to a thickness of 100 mm and widths of 1300, 1600, 2000, and 2300 mm. The machines are used for unwinding and subsequent lamination for further processing in the following machine. The machine is equipped with a foot switch, which facilitates work on the machine. The maximum processing speed of the material is 20 m/min. The machine is designed with the highest regard for operator safety, and all hazardous parts are covered during operation.

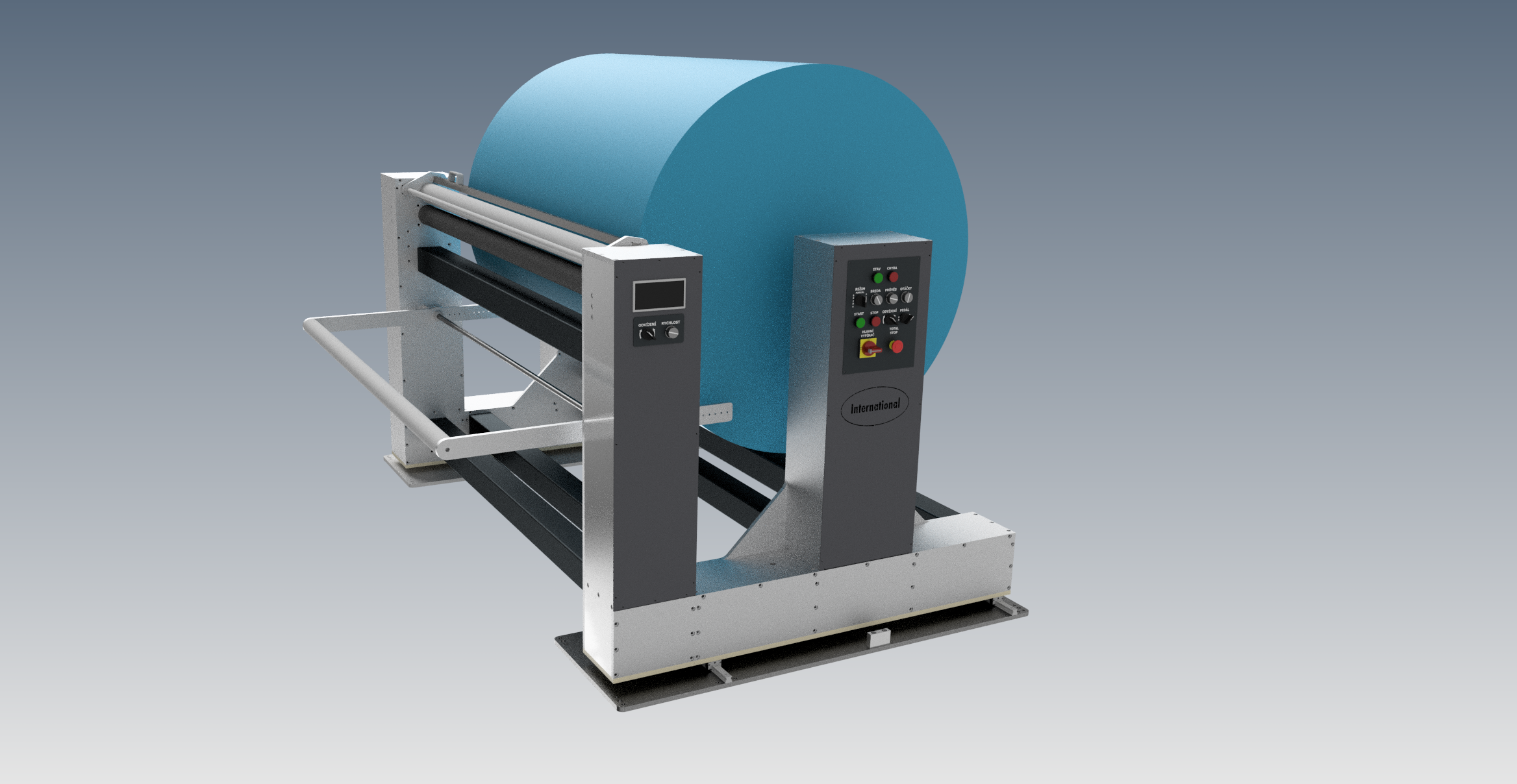

ICZ 1600-EASY R Laminator

Machines designed for lamination using heat-activated or cold adhesive materials up to a thickness of 55 mm and widths of 1300, 1600, and 2300 mm. The machines serve for laminating, rewinding. The machine is equipped with a foot switch, which facilitates work on the machine. The maximum processing speed of the material is 20 m/min. The machine is designed with the highest regard for operator safety, and all hazardous parts are covered during operation. The machines are manufactured with a modular structure and can be adjusted based on requirements of the customer.

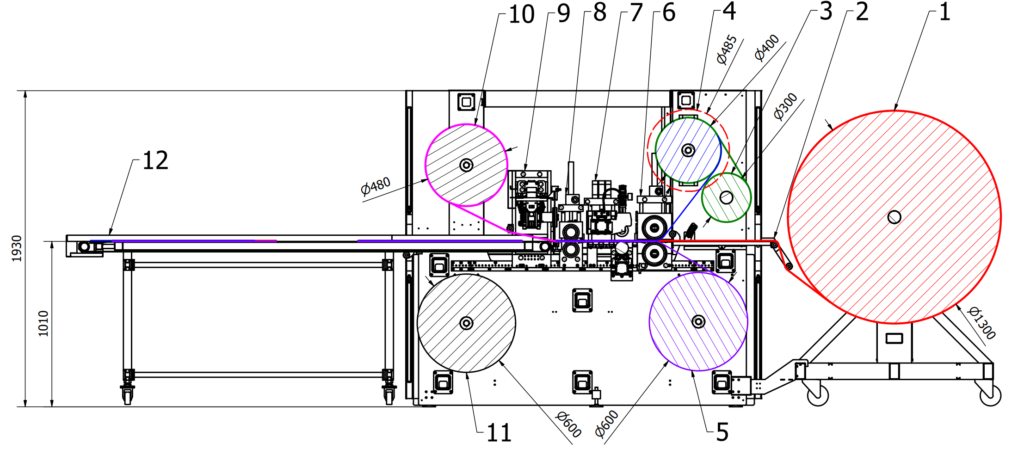

Machine Features

Self standing unwier (Double side locking system - 1300 mm / 800kg)

Entrance table

Liner rewinder (Double side locking system - 300 mm / 200kg)

Unwinder (One side locking system - 400 mm / 100 kg) - Diameter without remowing the liner 485 mm

Unwinder (One side locking system - 400 mm / 100 kg)

Longitudinal crush cutting unit

Puller unit

Cross cutting unit with cyrcular blade

Rewinder (One side locking system - 480 mm / 100 kg)

Rewinder (One side locking system - 600 mm / 100 kg)

Exit conveyor belt

Machine detailed features

External Jumbo Unwind (Position 1)

• Equipped with a 3” inflatable pneumatic expansion shaft.

• Dual quick locking chucks. Clamping chucks have jaws with a ‘V’ shape

for easy placement/removal of the shaft.

• 1300 mm max material outside diameter.

• The maximum weight of the roll is 800 kgs.

• Equipped with EMG brake for precise tension control

Entrance Table (Position 2)

• Adjustable inclination of the table to aid in material feeding and control.

• Equipped with guides and guide shafts for correct material alignment prior to the

lamination calendar

Liner Removal (Position 3)

• Material rewind on the inbound side, designed to remove a protection liner from the

upper unwind (Pos. 4)

• Equipped with a 3” inflatable pneumatic expansion shaft.

• Dual quick locking chucks. Clamping chucks have jaws with a ‘V’ shape for easy

placement/removal of the shaft.

• Millimetre ruler guide to aid in core placement on expansion shaft

• The maximum diameter of the wound roll is 300 mm.

• The maximum weight of the roll is 800 kgs.

• Winding tension is controlled by an adjustable electromagnetic clutch.

Upper PSA Unwind (Position 4)

• PSA unwind on the upper inbound side, designed to unwind PSA

• Equipped with a 3” inflatable pneumatic expansion shaft.

• Millimetre ruler guide to aid in roll placement on the expansion shaft

• The maximum diameter of the roll is 485 mm.

• The maximum weight of the roll is 100 kgs when open, and 800 kgs when closed.

• Cantilever upper shaft with single locking ‘V’ shape chuck.

• Unwind tension is controlled by an adjustable electromagnetic brake.

Lower PSA Unwind (Position 5)

• PSA unwind on the lower inbound side, designed to unwind PSA.

• Equipped with a 3” inflatable pneumatic expansion shaft.

• Millimetre ruler guide to aid in roll placement on the expansion shaft

• The maximum diameter of the roll is 600 mm.

• The maximum weight of the roll is 100 kgs when open, and 800 kgs when closed.

• Cantilever lower shaft with single locking ‘V’ shape chuck.

• Unwind tension is controlled by an adjustable electromagnetic brake.

Laminating Calendar (Position 6)

• Lower cylinder with silicone cover with heating element and adjustable temperature to

100° Celsius w/ sensor for temperature regulation.

• Lower calendar driven via servo motor for precise indexing tolerances.

• Upper cylinder with silicone cover with heating element and adjustable temperature to

100°Celsius w/ sensor for temperature regulation.

• Motorized Programable Gap between cylinders via DC motors, with linear encoder

feedback for precise adjustments in increments of 0.1mm.

• Adjustable gap between cylinders from 0-100mm.

Longitudinal Slitting Unit (Position 7)

• Cutting by using score/crush cutting system against inter-changeable nylon sleeves.

• Equipped with 5 standard circular blades @ 200mm OD x 70mm ID x 2mm T–

maximum material thickness = 50mm.

• Upper and lower counter-roll support device to avoid deflection.

• Synchronous lifting of the blade holder shaft via DC motor, with position sensor for

precise adjustments in increments of 0.1mm.

• Upper and lower shafts independently driven by their own motor with programmable

settings of each speed.

Pulling Nip – 2 nd Calendar (Position 8)

• Device designed for final lamination and pulling the material and keeping proper

tension through the longitudinal slitting station.

• Both cylinders are covered by anti-adhesive surface.

• Lower calendar driven via servo motor for precise indexing tolerances.

• Motorized Programable Gap between cylinders via DC motors, with linear encoder

feedback for precise adjustments in increments of 0.1mm.

• Adjustable gap between cylinders from 0-100mm.

Transversal Cross Cutting Unit (Position 9)

• Device designed for the transversal cutting (sheeting) of the material.

• Programmable length of cut and driven by a servo motor for precise indexing

tolerances of +/- 0.1mm.

• Cutting by 300mm OD driven circular blade – Maximum thickness = 30mm with

pressing bar, maximum thickness of 70mm without pressing bar in use.

• Option to add a 360mm OD circular blade for a maximum thickness of 100mm.

• Automatic single sided grinding device to sharpen the knife.

• Pneumatic nozzle, to lubricate the knife.

• Felt wiper to help clean surface of the knife.

• Pressing bar, to hold the material during the cutting cycle.

Upper Rewind (Position 10)

• Upper Material Rewind equipped with a 3” inflatable pneumatic expansion shaft on

the outbound side.

• Millimetre ruler for easy placement of the of the core.

• The maximum finished diameter roll is 600 mm.

• The maximum weight of the roll is 100 kgs when open, and 800 kgs when closed.

• Cantilever upper shaft with single locking ‘V’ shape chuck.

• Winding tension is controlled by adjustable electromagnetic clutch.

Lower Rewind (Position 11)

• Upper Material Rewind equipped with a 3” inflatable pneumatic expansion shaft on

the outbound side.

• Millimetre ruler for easy placement of the of the core.

• The maximum finished diameter roll is 600 mm.

• The maximum weight of the roll is 100 kgs when open, and 800 kgs when closed.

• Cantilever upper shaft with single locking ‘V’ shape chuck.

• Winding tension is controlled by adjustable electromagnetic clutch

Motorized Exit Conveyor (Position 12)

• Motorized Conveyor is equipped with wheels and quick electrical connection for easy

addition/removal from the machine line.

• Width of conveyor: 1680 mm

• Length of conveyor: 2800 mm

• Working height of the conveyor: 1020mm

Control Panel (Position 13)

• OMRON PLC and Touchscreen HMI with additional analog inputs/outputs for

complete control of the machine.

• Automatic programs (200 Recipes Total) for processing the material according to the

stored settings.

• Manual programs for setup and simple operations

• Counting of processed meters and pieces

• Movable on the body of machine for ease of use – single operator control.

CE Certificate of Conformity

• Safety elements of the machine include both front & rear Class 4 photoelectric barriers

(top and bottom), polycarbonate side guards with safety interlocks (machine stops

when opened but does not lose tension), & emergency stops.

• Certified with ISO 9001 quality management system & also adhere to ISO 14001

environmental standards.

virtual showroom

Material Handling Solutions

International Unwinders-Rewinders

PDF - 720 KB

The machine is equipped with:

Dancer: A sensor for monitoring material sag, controlling the drive shaft based on its data. Winding with sag allows for reduced stretching during material uptake

The machine is equipped with:

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Sensor: Monitors material sag, adjusting winding speed accordingly

The machine is equipped with:

Dancer: A sensor for monitoring material sag, facilitating reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Side Control: A device for aligning winding; it adjusts the position lightly if the material is unwound off-center.

The machine is equipped with:

Dancer: A sensor for monitoring material sag, optimizing drive shaft control for reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder

The machine is equipped with:

Dancer: For sag monitoring and optimized drive puller, ensuring reduced material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: Ensures precise winding alignment, adjusting position if material is unwound off-center.

The machine is equipped with:

Dancer: For sag monitoring and optimized drive shaft control, minimizing material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: For accurate winding alignment, making slight adjustments if material is unwound off-center

The machine is equipped with:

Loader: A device for enhanced material handling, automatically raised by the machine for improved efficiency.

Puller: Assists the drive during winding

The machine is equipped with:

Holder: A device for shaft retention, with a maximum capacity of 4 units.

Downloads

International + MSC Brochure.pdf

PDF - 6.3 MB

Download ICZ_1600_5H Brochure

PDF - 164 KB

Download Laminators Brochure

PDF - 5 MB