International

ICZ 1600 PK

MAXIMAL WORKING WIDTH 1600 MM

Machines designed for lamination using heat-activated or cold adhesive materials up to a thickness of 55 mm and widths of 1300, 1600, and 2300 mm. The machines serve for laminating, rewinding. The machine is equipped with a foot switch, which facilitates work on the machine. The maximum processing speed of the material is 20 m/min. The machine is designed with the highest regard for operator safety, and all hazardous parts are covered during operation. The machines are manufactured with a modular structure and can be adjusted based on requirements of the customer.

- The device is meant for lamination of the materials

- Values of the processed material (maximal)

- Width of roll: 1600 mm

- Diameter of entrance roll: 500 mm

- Weight of entrance roll: 200 Kg

- Thickness of material: 55 mm

- Maximal speed of lamination 20 m/min

- Control System

- A flat screen

- A safety equipment, photocell and safety button

- The machine program

- All axes are servo control

- Pre-adjustable programs

- Manual in English language

- Certificate of Conformity

Equipment of the Machine

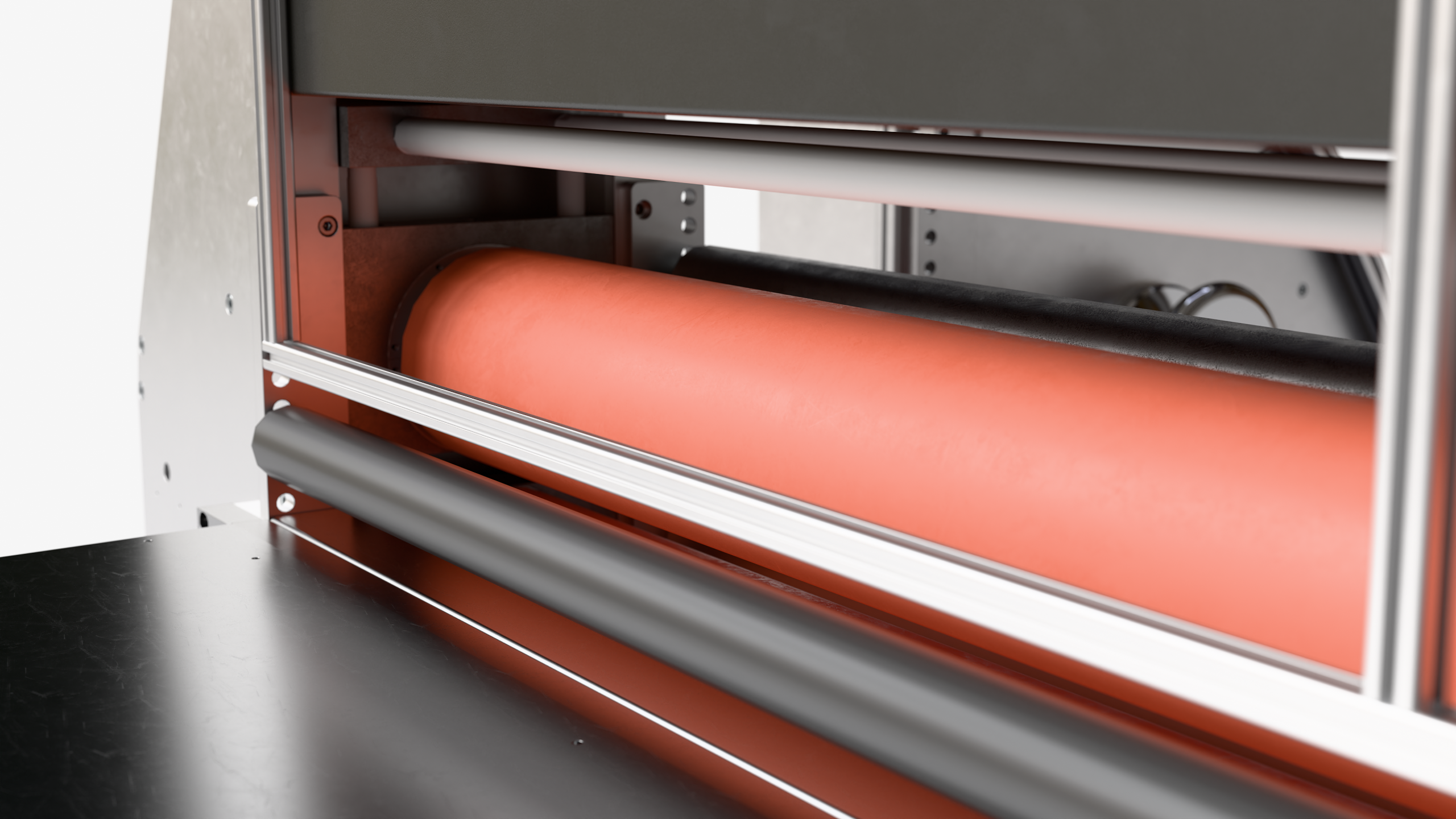

Lamination Unit:

- Lower cylinder with silicon cover.

- Upper cylinder with silicon cover.

- Both cylinders with heating elements.

- Adjustable temperature between room temperature and 100 °C by using control panel.

Unwinders:

- Determined for unwinding material to roll with parameters:

- Maximal width: 1600 mm

- Maximal diameter: 500 mm

- Maximal weight: 200 kg

- Motorised winding settable by control panel with adjustable speed of winding and adjustable tension.

- Pneumatic expansion shaft

- For the material with the core 3“.

- Fastening of the material by air inflation of the shaft.

- Fastening of shafts by using fast locking system on both sides

- The shaft equipped with the ruler for easy placing of the machine.

Control Panel:

- Control of the machine by using touch screen and few analogue buttons.

- Automatic programs for processing the material according setting.

- Manual program for basic operations.

- Counting of processed meters and pieces.

SAFETY ELEMENTS OF THE MACHINE

- Cover

- Microswitches

- Optical barriers

- Safety elements proposed for max possible prevention of dangerous situations during machine operation.