TECHNOLOGY ADVANTAGES

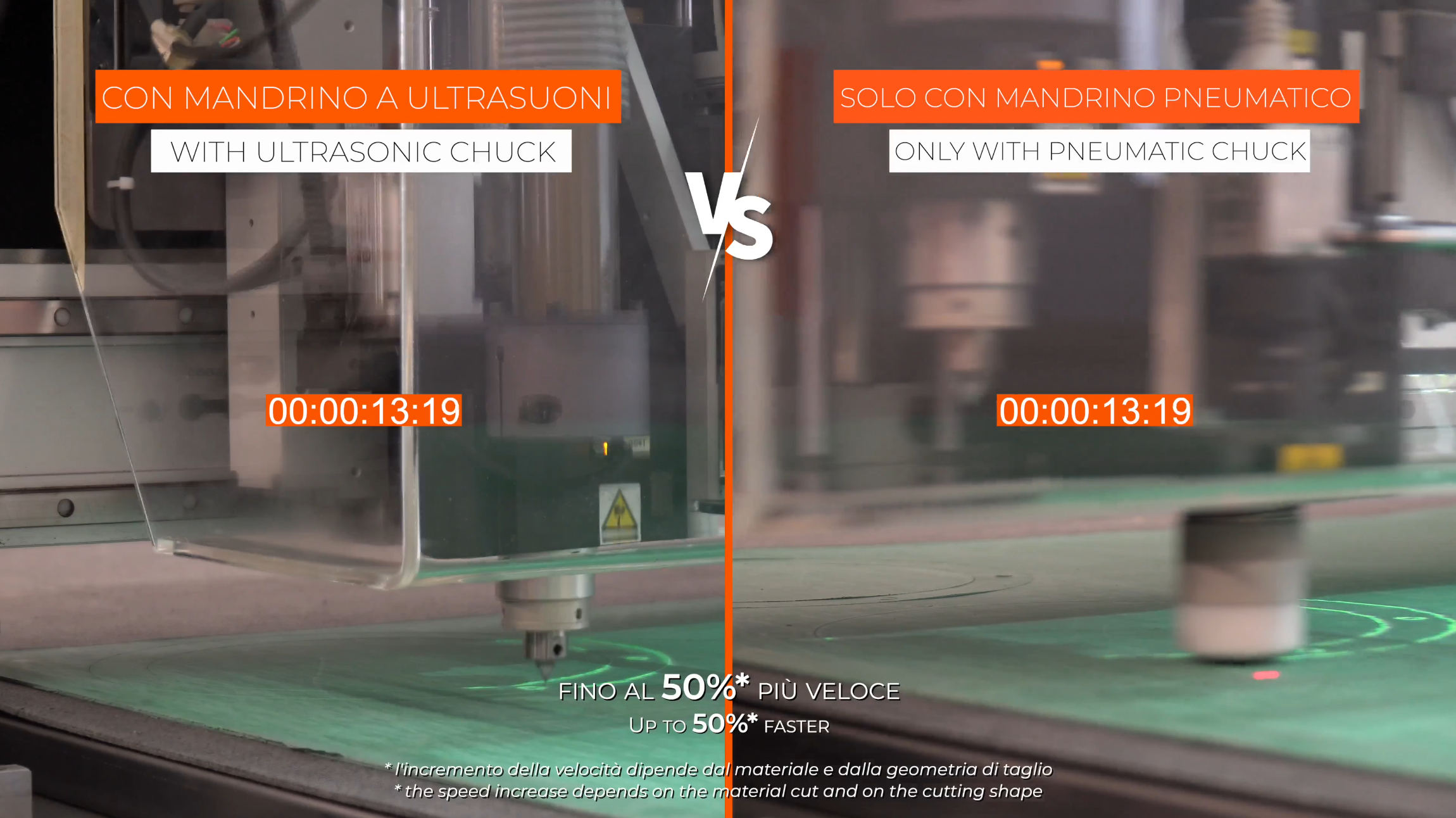

INCREASING PRODUCTIVITY

- Reduced cutting effort

- Reduced maintenance

- Cutting velocity increased

- Cutting until 125mm

- Continuous work

- No grip on tool

- Embeddable solutions

- Easy handling and set-up

IMPROVING CUTTING QUALITY

- No thermal degradation

- No fraying

- No dust

ULTRASONIC CUTTING END-EFFECTORS

Range of Products

SONIBLADE L

- CNC machines/robots

- Honeycomb cutting and surface machining

- Thickness up to 125mm

SONIBLADE M

- CNC machines/robots

- Composites cutting

- Thickness up to 35mm

SONIBLADE S

- ATL/AFP machines and robots

- Composites cutting

- Thickness up to 2mm

SONIBLADE T

- XY cutting tables

- Composites/Elastomer cutting

- Thickness up to 15mm

SONIBLADE T | XY cutting tables

Slip Ring: For infinite rotation

Attachment Area Ø 40mm

Indexed Blades: Always mounted in the same position

Length: 350mm

Features

- Ultrasonic generator: 30KHz

- Up to15m of ultrasonic coaxial wire

- Automated cooling of the ultrasonic components

- Cutting speed up to 150m/min

- Communication provided through the HMI of your machine

BLADE RANGE

SONIBLADE M | XY cutting tables

Slip Ring: For infinite rotation

Attachment Area Ø 77mm

Indexed Blades: Always mounted in the same position

Length: 348mm

Features

- End-effector: integrable on cutting tables

- Cutting speed up to 150m/min

- Ultrasonic generator: 20KHz

- Automated cooling of ultrasonic components connection

SONIBLADE M | BLADES RANGE

one device for longer blades

35mm

25mm

one device for blades up to 15mm

15mm

10mm

8mm

Single layer 4mm

soniblade t and m | applications

RAW MATERIALS

- Honeycomb: NOMEX, Aramid, Aluminum, Foam

- Composites: Carbon, Aramid, Glass (dry fiber and pre-impregnated)

- Other materials: Elastomer, Cardboard, Insulation material, Fabrics, Leather, Rubber, Gasket