International

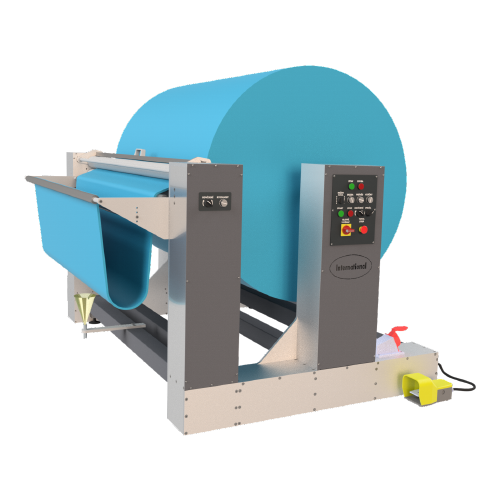

Unwinds - Winders

Un-rewinding machines

The machine is equipped with:

• Dancer: A sensor for monitoring material sag, controlling the drive shaft based on its data. Winding with sag allows for reduced stretching during material uptake.

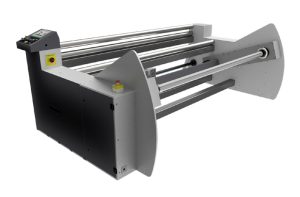

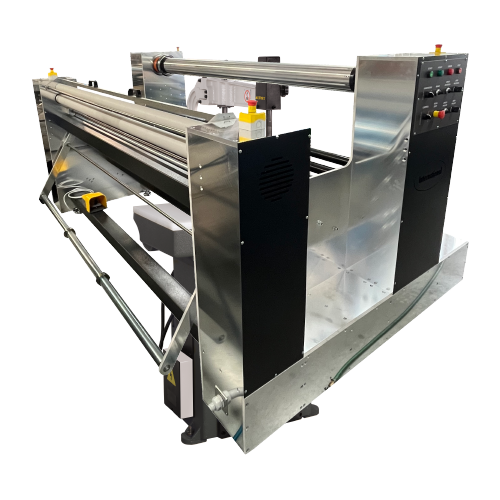

ICZ UNW SC

The machine is equipped with:

• Dancer: A sensor for monitoring material sag, facilitating reduced stretching during material uptake.

• Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

• Side Control: A device for aligning winding; it adjusts the position slightly if the material is unwound off-center.

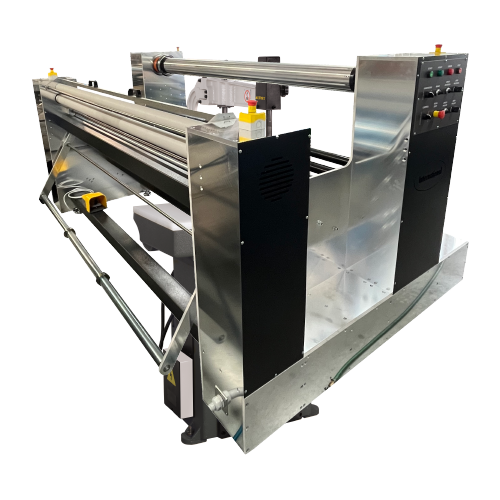

ICZ UNW S

The machine is equipped with:

• Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

• Sensor: Monitors material sag, adjusting winding speed accordingly.

ICZ UNW R

The machine is equipped with:

• Dancer: A sensor for monitoring material sag, optimizing drive shaft

control for reduced stretching during material uptake.

• Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

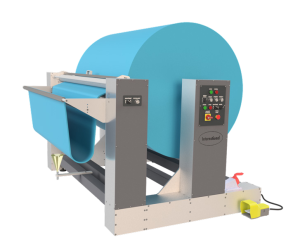

ICZ UNW CR1

The machine is equipped with:

• Dancer: For sag monitoring and optimized drive puller, ensuring reduced material stretching during uptake.

• Puller: Assists the drive during winding.

• Side Control: Ensures precise winding alignment, adjusting position if material is unwound off-center.

ICZ UNW ARM

The machine is equipped with:

• Loader: A device for enhanced material handling, automatically raised by the machine for improved efficiency.

• Puller: Assists the drive during winding.

ICZ UNW CR2

The machine is equipped with:

• Dancer: For sag monitoring and optimized drive shaft control, minimizing material stretching during uptake.

• Puller: Assists the drive during winding.

• Side Control: For accurate winding alignment, making slight adjustments if material is unwound off-center.

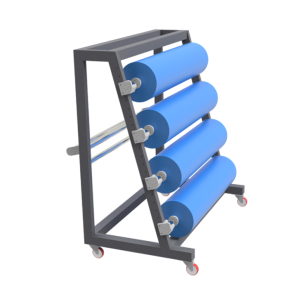

ICZ UNW MF

The machine is equipped with:

• Holder: A device for shaft

retention, with a maximum capacity of 4 units.

ICZ 1600 UNW E

ICZ 1600 UNW R

ICZ 1600 UNW S

ICZ 1600 UNW SC

ICZ 1600 UNW CR2/S

The width of the workspace for the material varies according to the type of the machine: 1300, 1600 and 2300 MM

| Machine Types | Processing width | Dancer | Puller | Sensor | type | Side control | ||

| Cradle | Shaft | Cradle + Shaft | ||||||

| ICZ 1600 UNW E | 1600 mm | x | x | |||||

| ICZ 1600 UNW R | 1600 mm | x | x | x | ||||

| ICZ 1600 UNW S | 1600 mm | x | x | x | ||||

| ICZ 1600 UNW SC | 1600 mm | x | x | x | x | |||

| ICZ 1600 UNW CR1 | 1600 mm | x | x | x | possible | |||

| ICZ 1600 UNW CR2/S | 1600 mm | x | x | x | possible | |||