ATOM FlashCut

EASY 888 Series

The ATOM FlashCut EASY 888 Knife Cutting Table is the ideal dieless cutting solution for small and medium production of shoes and small leather goods.

The complete accessibility to the working surface, the possibility to place materials larger than the actual cutting surface due to the canti-levered beam structure & the back space for material support, the high brightness projectors for the layout & identification of piece codes during off-loading, and the double working area to optimize productivity make the ATOM FlashCut EASY 888 the perfect knife cutting system for shoe and leather goods factories. The cutting quality is excellent thanks to the mechanical accuracy of the machine’s axes (steel rack & pinion) and the powerful multi-tool cutting head which accepts all the traditional tools in the ATOM range to cut-punch-crease-mill-mark any shape. In particular, the pneumatic oscillating knife chuck, capable of cutting thick leather, shank board and multi-layer textiles up to 25mm in thickness.

Compact design, robust structure, reliable, economic but without compromises, the FlashCut EASY 888 is the new standard for cutting operations worldwide. In the 1970’s, the “classic” G888 Traveling Head Die Cutting Press became the reference for die cutting machines used in shoe & leather goods factories throughout the world. Today, thanks to over 65 years of experience and more than 250,000 cutting machines sold worldwide, ATOM introduces the FlashCut EASY 888 Knife Cutting Table; “Innovation in Tradition”.

Besides the traditional shoe & leather goods components, the ATOM FlashCut EASY 888 is the ideal dieless knife cutting system for gaskets in their various forms (tang graphite included), foams and laminated foams, rubber and it’s by-products, technical textiles and composites, adhesive laminates and similar products. In addition, the FlashCut EASY 888 can be coupled with a wide variety of material handling options to create a complete narrow web dieless converting system for roll-roll kiss cutting applications.

FlashCut EASY 888 VRX

VRX, the new Knife Cutting System with Automatic Visual Detection developed by ATOM, is ideal for printed materials and trimming.

Innovative knife cutting system with automatic visual detection, engineered for printed materials and re-cut. The high-resolution cameras allow to automatically recognize multiple different prints based on the color contrast between the material and the figures. The Pattern Matching modality allows the machine to automatically find pre-loaded shapes on the material.

Technical Spefications

| Model | Working Area | Max Absorption |

| Easy 888 VRX | 1600x600mm | 6.8 KW |

Downloads

Download FlashCut EASY 888 VRX Brochure

PDF - 55.19 KB

Range - Models

Easy 222

Working Area (MM)

1000x600

Max Absorption (KW)

5,1

Sizes (MM)

1600x1235x2190h

Description

The most compact model, ideal for sample department and small lots. Suitable for a wide range of materials and applications.

Easy 222 Floorplan

Easy 888

Working Area (MM)

1600x600

Max Absorption (KW)

6,8

Sizes (MM)

2220x1235x2680h

Description

Two sectors vacuum system and two indipendent working areas. Suitable for cutting leather and synthetic materials. For sample department and small-medium lots.

Easy 888 Floorplan

Easy 888 M25

Working Area (MM)

2500x800

Max Absorption (KW)

9,8

Sizes (MM)

3165x1780x2474h

Description

Cutting surface with partitioned vacuum system, two working areas and 5 or 7 tools cutting head. Suitable for small and medium productions of footwear and leather goods.

Easy M25 Floorplan

Easy 888 L30

Working Area (MM)

3000x1000

Max Absorption (KW)

12,2 - 24(mod p2)

Sizes (MM)

13,5 3765x1955x2805h

Description

Same features of M25 model, but with a wider working area for half-hides and shoulders. For productions of shoes, leather goods and soles.

Easy L30 Floorplan

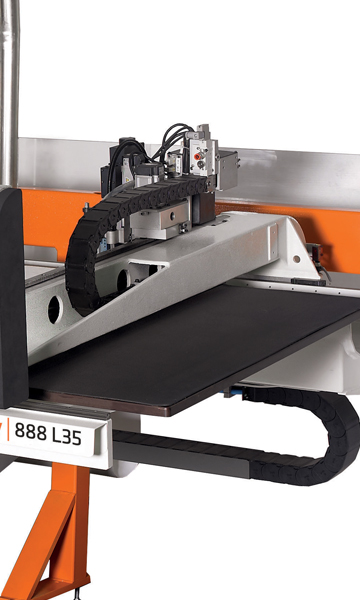

Easy 888 L35

Working Area (MM)

3500x1000

Max Absorption (KW)

14,1

Sizes (MM)

5000x2500x2805h

Description

Two independent 5 or 7 tools cutting heads. The Easy series cutting system for high productions.

Easy L35 Floorplan

Modular Heads

5-Tool Head

The 5-tool cutting head increases the overall versatility of the ATOM Flashcut and is one of the key factor of its success - the ability to total cut, score cut (partial depth cut) & kiss cut with one module, two auxiliary stations that can be equipped with rotating punches for precise small diameter holes, a creaser wheel or kiss cutting knife, a 4th station that includes a marking pen to apply part #’s and trademarks and a 5th non-rotating punch station that is used on light-weight materials. With this versatile head, the Flashcut now becomes a multi-functional production system for a variety of market sectors.

7-Tool Head

The 7-Tool head offers the same combination as the 5-Tool head yet adds two additional rotating punching-drilling stations for increased flexibility. The pneumatically controlled belt-driven punch stations are primarily used for perforating leather, or for punching small diameter holes in gaskets & textile materials. Four independent punch tools on a single head allows for different hole sizes to be produced on the same job. To accommodate different applications, punches are available in sizes ranging from 0.5mm to 8mm & are made from tungsten carbide or high-speed steel (HSS).

5-Tool Head

The 5-tool cutting head increases the overall versatility of the ATOM Flashcut and is one of the key factor of its success - the ability to total cut, score cut (partial depth cut) & kiss cut with one module, two auxiliary stations that can be equipped with rotating punches for precise small diameter holes, a creaser wheel or kiss cutting knife, a 4th station that includes a marking pen to apply part #’s and trademarks and a 5th non-rotating punch station that is used on light-weight materials. With this versatile head, the Flashcut now becomes a multi-functional production system for a variety of market sectors.

7-Tool Head

The 7-Tool head offers the same combination as the 5-Tool head yet adds two additional rotating punching-drilling stations for increased flexibility. The pneumatically controlled belt-driven punch stations are primarily used for perforating leather, or for punching small diameter holes in gaskets & textile materials. Four independent punch tools on a single head allows for different hole sizes to be produced on the same job. To accommodate different applications, punches are available in sizes ranging from 0.5mm to 8mm & are made from tungsten carbide or high-speed steel (HSS).

Tooling Combinations

Side auxiliary tools can include rotating punches/drilling stations, kiss cut tool, creaser wheel for carton stock or thin plastics, or a 45° angle knife. Only available on the 5-Tool or 7-Tool modular head.

Side auxiliary tools can include rotating punches/drilling stations, kiss cut tool, creaser wheel for carton stock or thin plastics, or a 45° angle knife. Only available on the 5-Tool or 7-Tool modular head.

The Drag Knife Chuck (DKC) is ideal for total cutting rigid materials like thin compressed non-asbestos, laminates & plastics up to 6mm (1/4”) in thickness.

The Electric Oscillating Knife Chuck (EOK), is ideal for cutting softer, low-medium density materials like thin foams, soft rubber, pure graphite, leather, laminates, adhesives and similar products.

The pneumatic milling chuck, or PMC, was designed for companies that want the flexibility for light-duty milling applications for rigid materials, primarily plastics (ABS, UHMW, PP, PE etc..), that are not capable of being cut with the traditional pneumatic oscillating knife chuck.

The Pneumatic Oscillating Chuck (POC), is an air driven tool engineered for cutting the most difficult materials but is also used for cutting thick, soft substrates as well.

The Powered Rotary Chuck (PRC), is designed for cutting difficult fibrous materials, both uni-lateral & bi-lateral weaves, at a high rate of speed. The PRC is suitable for processing carbon fibers, Kevlar, fiber-glass, aramid and technical textiles & composites in general.

+PLUS|Flashcut Easy

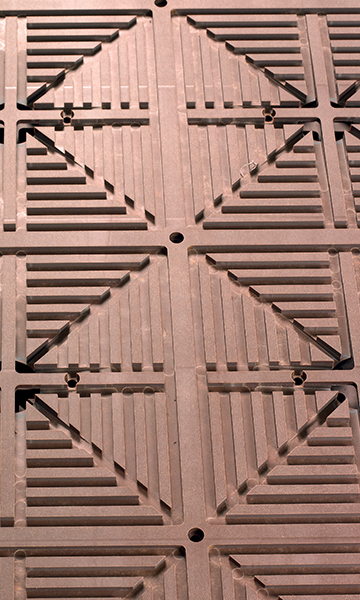

Partitioned Vacuum System

Powerful, partitioned and adjustable vacuum system. Best fixing during cutting and highest energy saving.

Performance and Reliability

Perfect quality and cutting speed, accurate mechanic engineering. State-of-the-art electronics.

Two Cutting Areas

Two working areas to collect the cut pieces on production time. Labor saving.

Two Cutting Heads

Two independent working areas to boost productivity.

Acquisition Systems

In-line and off-line leather acquisition systems. Digital pen for marking quality areas.

Optimized Nesting

Customized automatic nesting system. User friendly interface. Reduction of the process times and maximum material yield.

Applications

Solid structure and cutting precision even for fields different from footwear and leather goods.

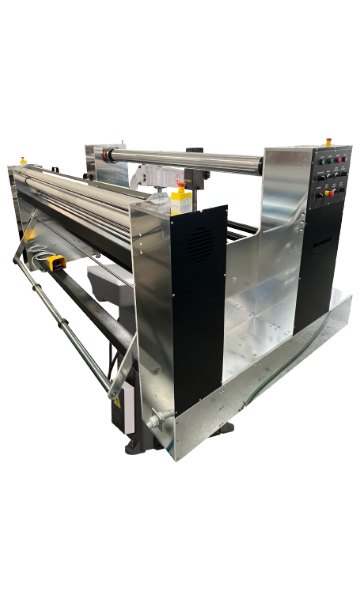

Modular Material

Handling Solutions

Standard & custom engineered material unwinds stands & winders, feeding and spreading machines, sheet-loaders, and in-line loading & off-loading tables.

Downloads

Download EASY Series Brochure

PDF - 1.10 MB

Download FlashCut

EASY 222-888 Brochure

PDF - 331 KB

Download VRX Technology

Brochure

PDF 446 KB