ATOM FlashCut

Flex 2H Series

The ATOM FlashCut High Production Knife Cutting Systems, FLEX 2H Series, is a new dieless cutting technology combining flexibility and output.

ATOM knife cutting tables have a reputation as one of the fastest machines on today’s market. However, we realize the market is always looking for a more versatile & productive system. Therefore, we designed a cutting system with two independent multi-tool cutting heads available as a static bed for sheets or equipped with a transport cutting belt for processing materials in rolls.

The FLEX 2H Series boasts the same features & improvements in technology as the traditional FLEX Series. The solid steel rack and pinion system in place of a cogged belt increase the precision and operating speeds of the machine while the two pre-charged linear guide rails and enlarged beam adds to the robustness of the system. The new cutting surface with a higher degree of planarity coupled with the unique ‘smart’ partitioned zoned vacuum system add even more suction power improving cut quality and overall accuracy. With the option to add an overhead camera system for material contour recognition, projectors to visualize the cutting layout for assisted parts collection, the modular multi-tool cutting heads and the powerful yet simple to use production control software make the FlashCut “FLEX 2H” an efficient, versatile, powerful & highly productive CNC digital cutting system.

Engineered and designed to cut the hardest materials used in the petro-chemical, automotive, aerospace, composites & technical textiles, & packaging industries like compressed non asbestos, 1-2 layer steel inserted graphite, dense rubber, cross linked polyethylene foam, Kevlar, plastics, and many more. Since ATOM develops its technology in close collaboration with its clients, today it is able to offer the most advanced and most applicable cutting solution on the market – the new FlashCut ‘FLEX 2H’.

Range - Models

The 2H Series is available in both a Static (S) or Belt (B) configuration - except 6115, which is only available as a Static (S) table.

Flex 3026

Working Area (MM)

3050x2600

Max Absorption (KW)

1 Pump / 2 Pump

13,46 / 23,86

Description

Ideal for cutting materials of significant sizes. Combined with on-line or off-line scanning systems it is ideal for full hides.

FLEX 3026 Floorplan

Flex 4015

Working Area (MM)

4050x1550

Max Absorption (KW)

1 Pump / 2 Pump

13,46 / 23,86

Description

Greater length to optimize the cutting of 2-meter sheets or to add a second cutting head.

FLEX 4015 Floorplan

Flex 4020

Working Area (MM)

4050x2050

Max Absorption (KW)

1 Pump / 2 Pump

13,46 / 23,86

Description

Ideal system for processing bovine leather and splits, particularly in the furniture sector.

FLEX 4020 Floorplan

Flex 6115

Working Area:

6100x1550

Max Absorption (KW)

1 Pump / 2 Pump:

- /23,86

Description:

The maximum useful area of this range. Ideal solution for double cutting heads.

FLEX 6115 Floorplan

Modular Heads

5-Tool Head

The 5-tool cutting head increases the overall versatility of the ATOM Flashcut and is one of the key factor of its success - the ability to total cut, score cut (partial depth cut) & kiss cut with one module, two auxiliary stations that can be equipped with rotating punches for precise small diameter holes, a creaser wheel or kiss cutting knife, a 4th station that includes a marking pen to apply part #’s and trademarks and a 5th non-rotating punch station that is used on light-weight materials. With this versatile head, the Flashcut now becomes a multi-functional production system for a variety of market sectors.

7-Tool Head

The 7-Tool head offers the same combination as the 5-Tool head yet adds two additional rotating punching-drilling stations for increased flexibility. The pneumatically controlled belt-driven punch stations are primarily used for perforating leather, or for punching small diameter holes in gaskets & textile materials. Four independent punch tools on a single head allows for different hole sizes to be produced on the same job. To accommodate different applications, punches are available in sizes ranging from 0.5mm to 8mm & are made from tungsten carbide or high-speed steel (HSS).

5-Tool Head

The 5-tool cutting head increases the overall versatility of the ATOM Flashcut and is one of the key factor of its success - the ability to total cut, score cut (partial depth cut) & kiss cut with one module, two auxiliary stations that can be equipped with rotating punches for precise small diameter holes, a creaser wheel or kiss cutting knife, a 4th station that includes a marking pen to apply part #’s and trademarks and a 5th non-rotating punch station that is used on light-weight materials. With this versatile head, the Flashcut now becomes a multi-functional production system for a variety of market sectors.

7-Tool Head

The 7-Tool head offers the same combination as the 5-Tool head yet adds two additional rotating punching-drilling stations for increased flexibility. The pneumatically controlled belt-driven punch stations are primarily used for perforating leather, or for punching small diameter holes in gaskets & textile materials. Four independent punch tools on a single head allows for different hole sizes to be produced on the same job. To accommodate different applications, punches are available in sizes ranging from 0.5mm to 8mm & are made from tungsten carbide or high-speed steel (HSS).

Tooling Combinations

Side auxiliary tools can include rotating punches/drilling stations, kiss cut tool, creaser wheel for carton stock or thin plastics, or a 45° angle knife. Only available on the 5-Tool or 7-Tool modular head.

Side auxiliary tools can include rotating punches/drilling stations, kiss cut tool, creaser wheel for carton stock or thin plastics, or a 45° angle knife. Only available on the 5-Tool or 7-Tool modular head.

The Drag Knife Chuck (DKC) is ideal for total cutting rigid materials like thin compressed non-asbestos, laminates & plastics up to 6mm (1/4”) in thickness.

The Electric Oscillating Knife Chuck (EOK), is ideal for cutting softer, low-medium density materials like thin foams, soft rubber, pure graphite, leather, laminates, adhesives and similar products.

The pneumatic milling chuck, or PMC, was designed for companies that want the flexibility for light-duty milling applications for rigid materials, primarily plastics (ABS, UHMW, PP, PE etc..), that are not capable of being cut with the traditional pneumatic oscillating knife chuck.

The Pneumatic Oscillating Chuck (POC), is an air driven tool engineered for cutting the most difficult materials but is also used for cutting thick, soft substrates as well.

The Powered Rotary Chuck (PRC), is designed for cutting difficult fibrous materials, both uni-lateral & bi-lateral weaves, at a high rate of speed. The PRC is suitable for processing carbon fibers, Kevlar, fiber-glass, aramid and technical textiles & composites in general.

Material Handling Solutions

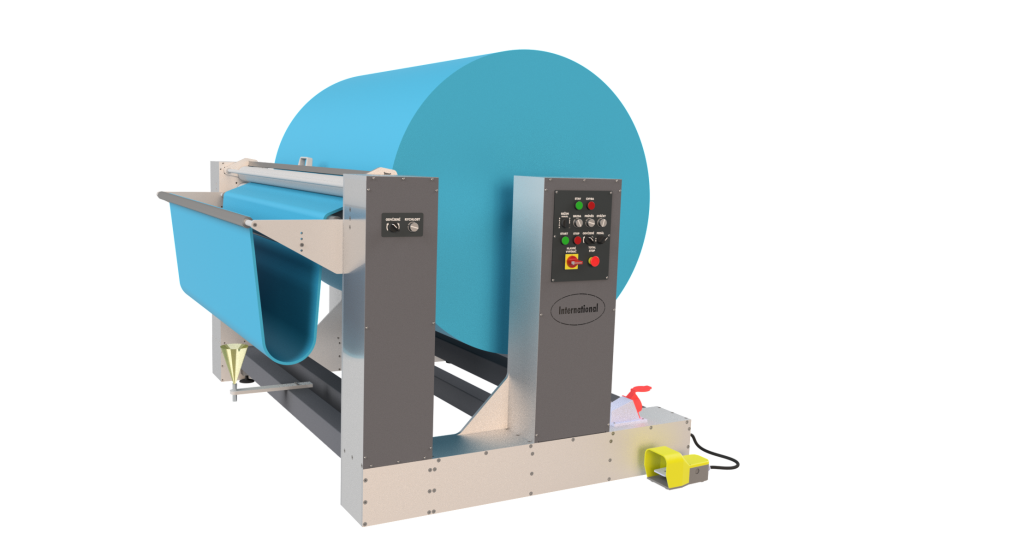

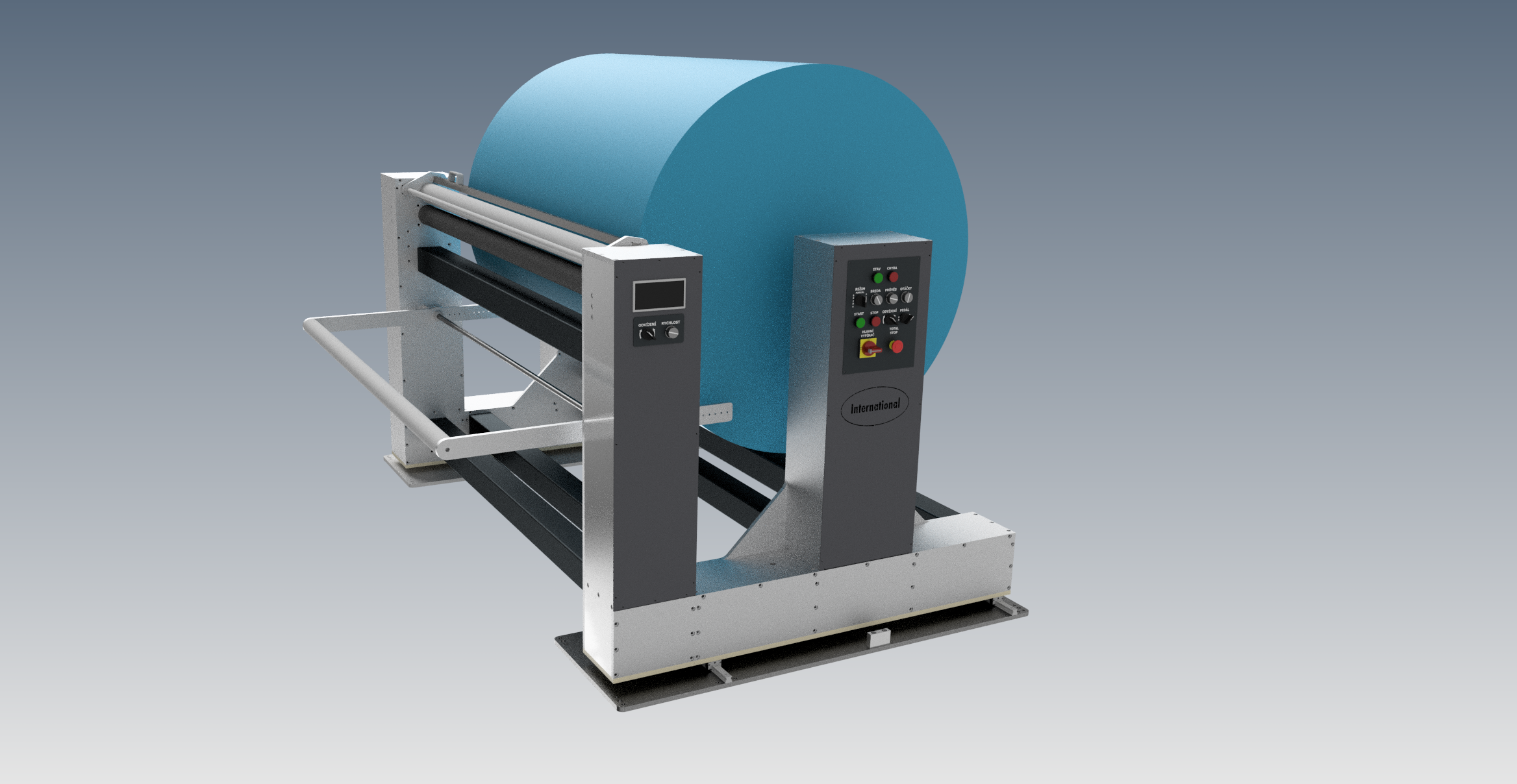

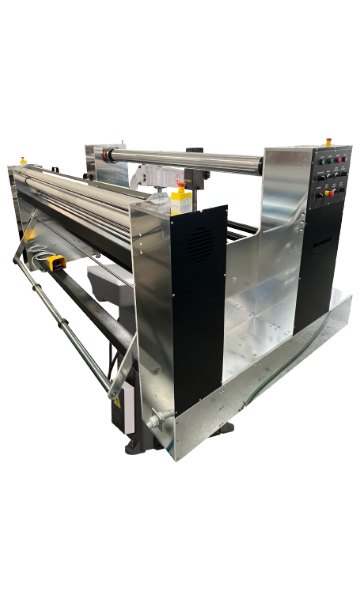

International Unwinders-Rewinders

PDF - 720 KB

The machine is equipped with:

Dancer: A sensor for monitoring material sag, controlling the drive shaft based on its data. Winding with sag allows for reduced stretching during material uptake

The machine is equipped with:

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Sensor: Monitors material sag, adjusting winding speed accordingly

The machine is equipped with:

Dancer: A sensor for monitoring material sag, facilitating reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Side Control: A device for aligning winding; it adjusts the position lightly if the material is unwound off-center.

The machine is equipped with:

Dancer: A sensor for monitoring material sag, optimizing drive shaft control for reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder

The machine is equipped with:

Dancer: For sag monitoring and optimized drive puller, ensuring reduced material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: Ensures precise winding alignment, adjusting position if material is unwound off-center.

The machine is equipped with:

Dancer: For sag monitoring and optimized drive shaft control, minimizing material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: For accurate winding alignment, making slight adjustments if material is unwound off-center

The machine is equipped with:

Loader: A device for enhanced material handling, automatically raised by the machine for improved efficiency.

Puller: Assists the drive during winding

The machine is equipped with:

Holder: A device for shaft retention, with a maximum capacity of 4 units.

+PLUS|Flashcut Flex

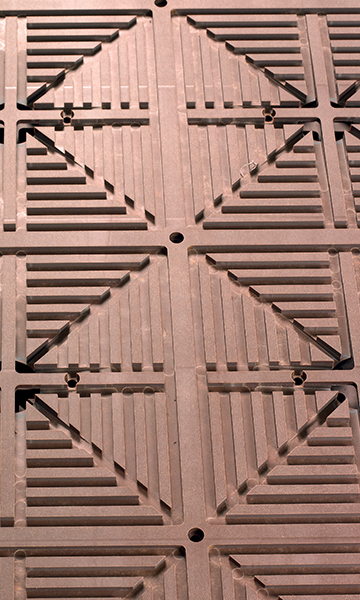

Partitioned Vacuum System

Powerful partitioned and adjustable vacuum system. Best material fixing during cutting with highest energy saving.

Performance and Reliability

Perfect quality and cutting speed. Precision mechanical engineering and state-of-the-art electronics.

Two Cutting Heads

Two independent cutting heads to increase productivity.

Optimized Nesting

Customized automatic nesting software. User friendly interface. Reduction of the process times and maximum material yield.

Static or Conveyorized Belt Cutting Surface

On the conveyorized models, the material feeding is carried out by the combination of the belt and two pincers mounted on the gantry.

Overhead

Projectors

Optimal clarity thanks to LED lamps which offer lower maintenance and a long life.

Acquisition

Systems

In-line and off-line Acquisition Systems optimize material yields and dramatically reduce the overall time for placing the shapes to be processed.

Modular Material

Handling Solutions

Standard & custom engineered material unwinds stands & winders, feeding and spreading machines, sheet-loaders, and in-line loading & off-loading tables.

Downloads

Download Flex Series Brochure

PDF - 241 KB

Download Flex 3026 B-3 Brochure

PDF - 331 KB

Download Automotive Sector

PDF - 375 KB

Download Oil and Gaskets Sectors

PDF - 654 KB