International

Shearing Machines

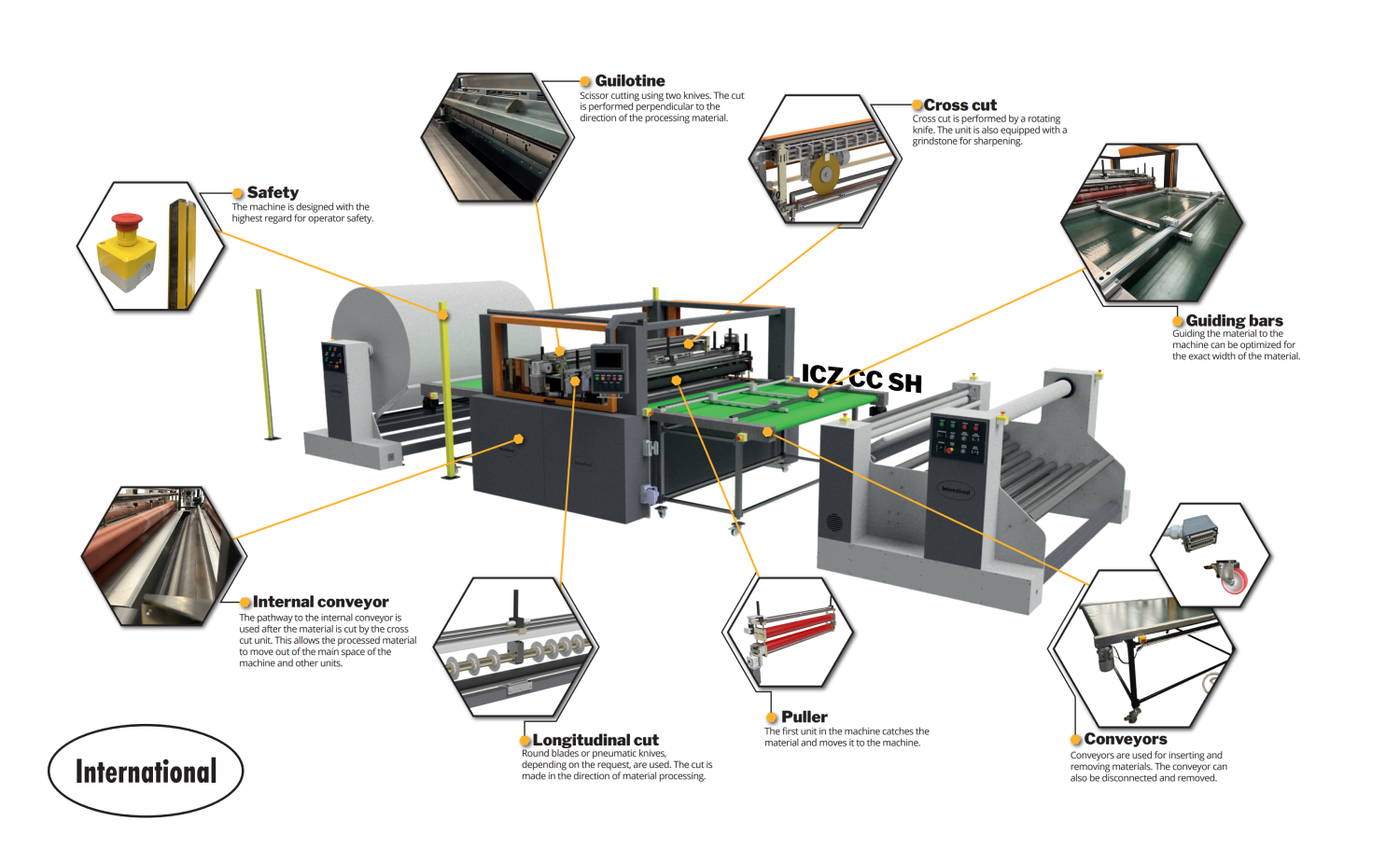

The machines are designed for formatting materials into predefined rectangular formats, which can be cut using longitudinal and transverse cutting units. The machine includes an input and output conveyor.

virtual showroom

Equipment range

ICZ SH

The machines are designed for formatting non-compressible materials into predefined rectangular formats, which can be cut using a guillotine unit and longitudinal cutting knives with material widths of 1300, 1600, and 2100 mm. The machine includes an input and output conveyor. It is equipped with a foot switch, which facilitates work on the machine. The maximum processing speed of the material is 20 m/min. The machine is designed with the highest regard for operator safety, and all hazardous parts are covered during operation. The machines are manufactured with a modular structure and can be adjusted based on requirements of the customer.

Dimensions and weight

| Type of Machine | Working width of the machine |

| ICZ 1300 SH | 1 300 mm |

| ICZ 1600 SH | 1 600 mm |

| ICZ 2100 SH | 2 100 mm |

International Sheeters

ICZ CC SH

The machine includes an input and output conveyor. It is equipped with a foot switch, which facilitates work on the machine. The maximum processing speed of the material is 20 m/min. The machine is designed with the highest regard for operator safety, and all hazardous parts are covered during operation. The machines are manufactured with a modular structure and can be adjusted based on requirements of the customer.

Dimensions and weight

| Type of Machine | Working width of the machine |

| ICZ 1300 CC SH | 1 300 mm |

| ICZ 1600 CC SH | 1 600 mm |

| ICZ 2100 CC SH | 2 100 mm |

Material Handling Solutions

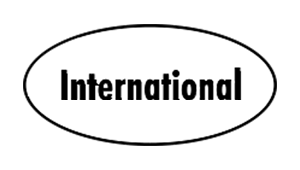

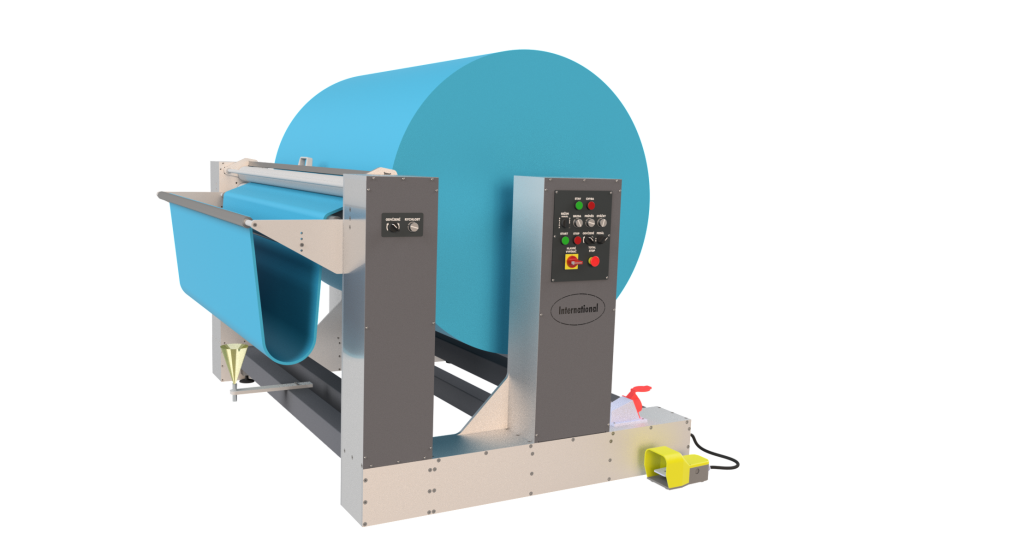

International Unwinders-Rewinders

PDF - 720 KB

The machine is equipped with:

Dancer: A sensor for monitoring material sag, controlling the drive shaft based on its data. Winding with sag allows for reduced stretching during material uptake

The machine is equipped with:

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Sensor: Monitors material sag, adjusting winding speed accordingly

The machine is equipped with:

Dancer: A sensor for monitoring material sag, facilitating reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Side Control: A device for aligning winding; it adjusts the position lightly if the material is unwound off-center.

The machine is equipped with:

Dancer: A sensor for monitoring material sag, optimizing drive shaft control for reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder

The machine is equipped with:

Dancer: For sag monitoring and optimized drive puller, ensuring reduced material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: Ensures precise winding alignment, adjusting position if material is unwound off-center.

The machine is equipped with:

Dancer: For sag monitoring and optimized drive shaft control, minimizing material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: For accurate winding alignment, making slight adjustments if material is unwound off-center

The machine is equipped with:

Loader: A device for enhanced material handling, automatically raised by the machine for improved efficiency.

Puller: Assists the drive during winding

The machine is equipped with:

Holder: A device for shaft retention, with a maximum capacity of 4 units.