International

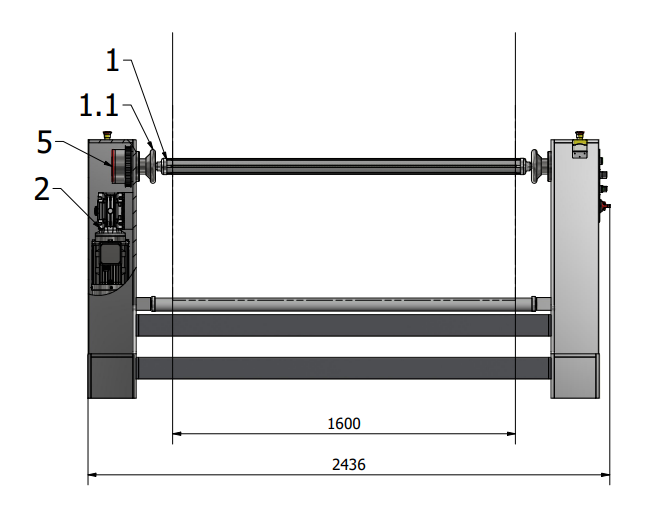

ICZ 1600-UNW E

MAXIMAL WORKING WIDTH 1600 MM

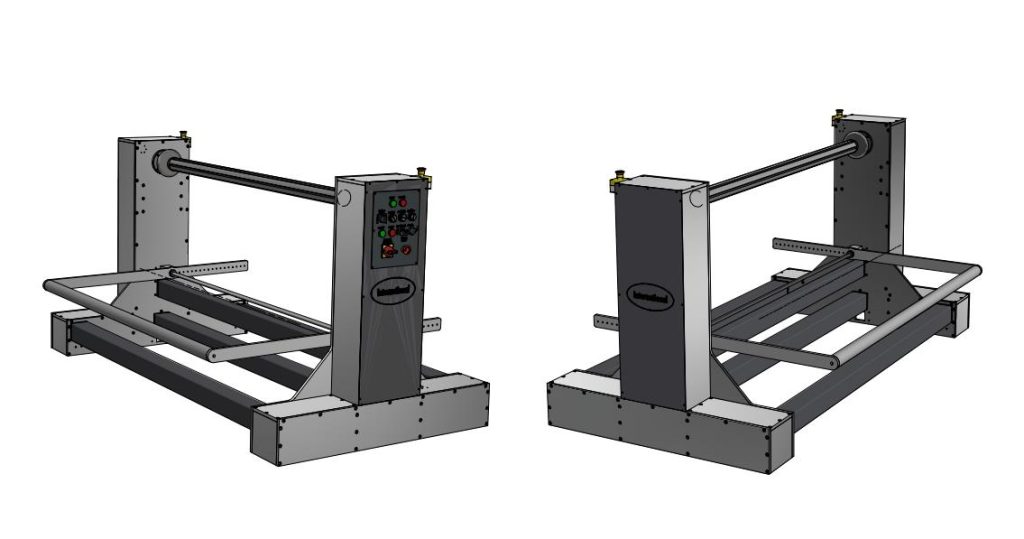

Our unwinding and rewinding machines are an essential part of our product portfolio, designed to ensure precise and controlled handling of materials. These machines facilitate efficient unwinding for processing.

Equipped with advanced tension and speed control systems, our machines guarantee optimal material tension and protection from damage throughout the process.

We offer unwinding and rewinding machines in the following standard working widths:

- 1300 mm

- 1600 mm

- 2300 mm

Custom configurations are available upon request.

Technical Specifications

- Application: Designed for precise and controlled unwinding of materials from rolls.

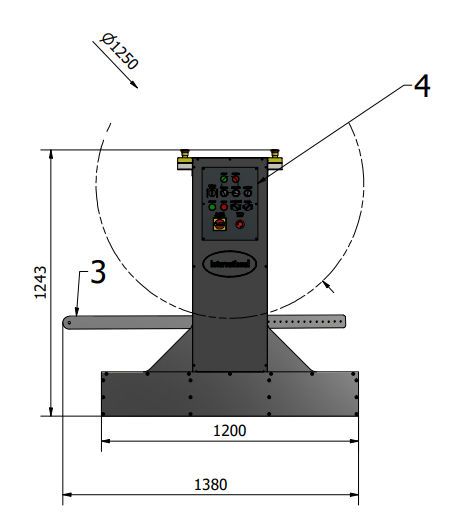

- Roll Parameters:

- Maximum width: 1600 mm

- Maximum diameter: 1200 mm

- Maximum weight: 500 kg

- Working Speed: 0–20 m/min

Key Features

Dancer: Automatically adjusts unwinding speed to maintain proper tension, preventing over-tension or slack.

Equipment of the Machine

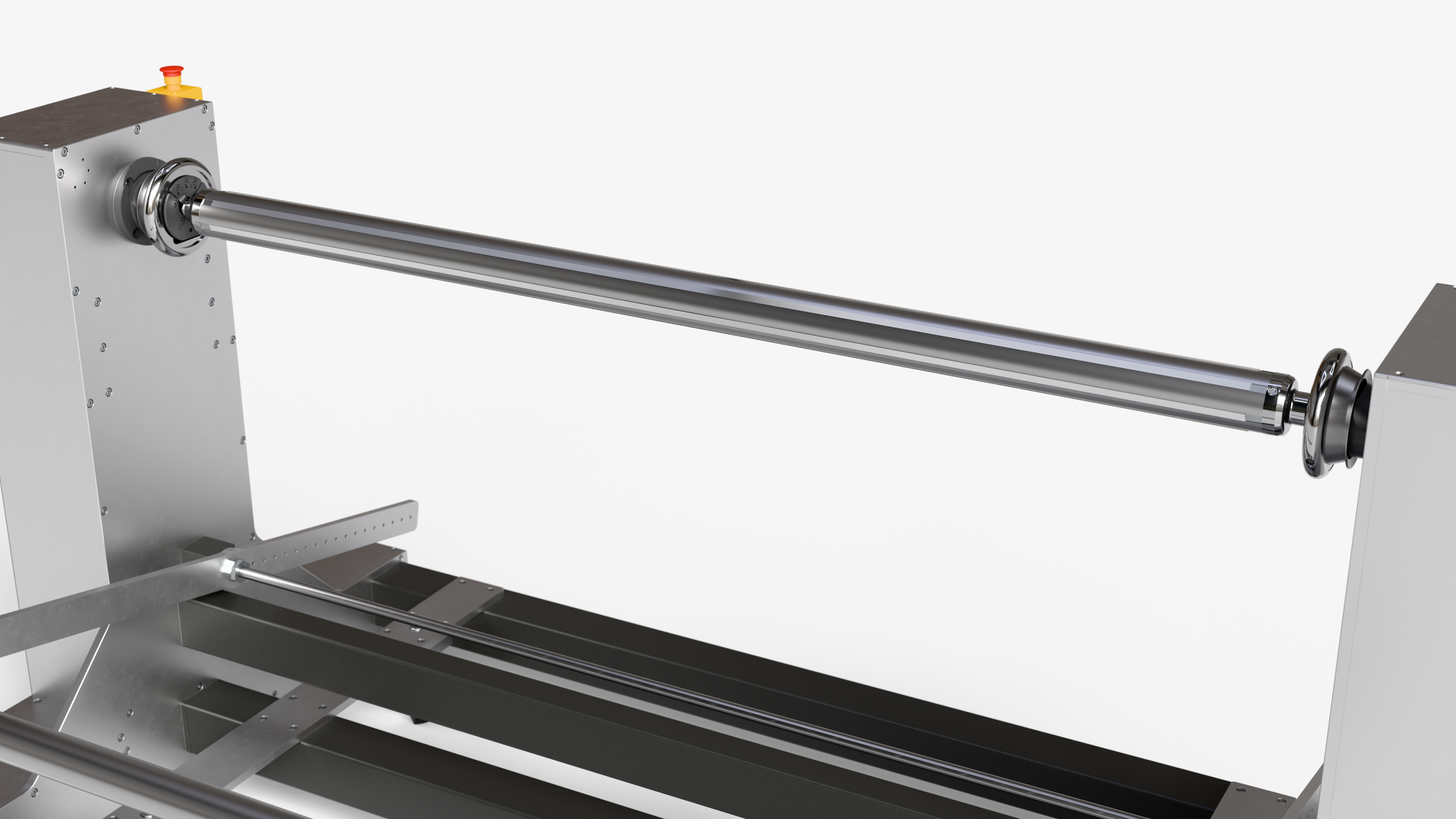

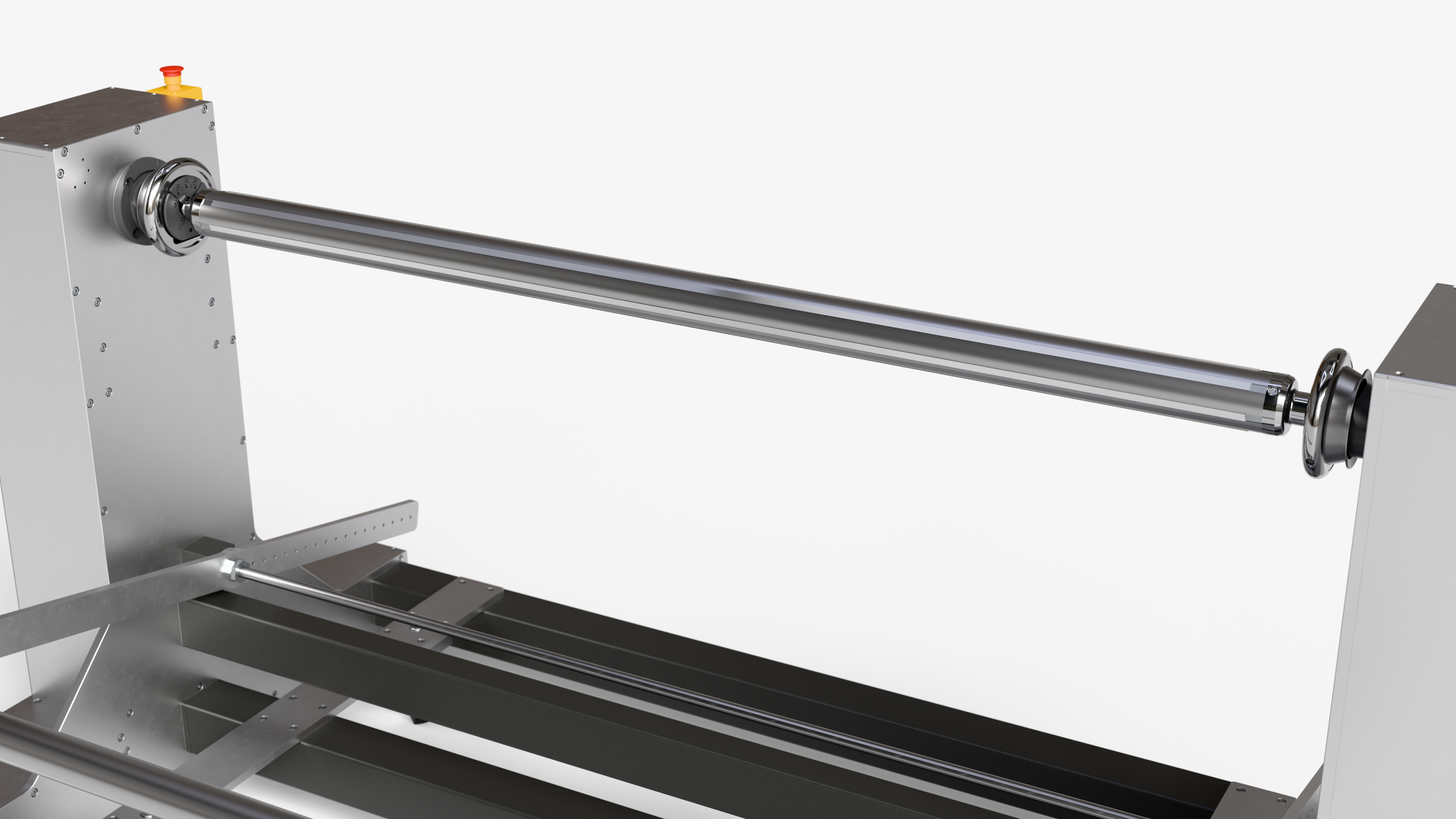

Shaft:

- Interchangeable shaft

- Quick-lock fastening system on both ends for secure and efficient shaft fixation.

- Shaft equipped with an alignment gauge to ensure precise material positioning.

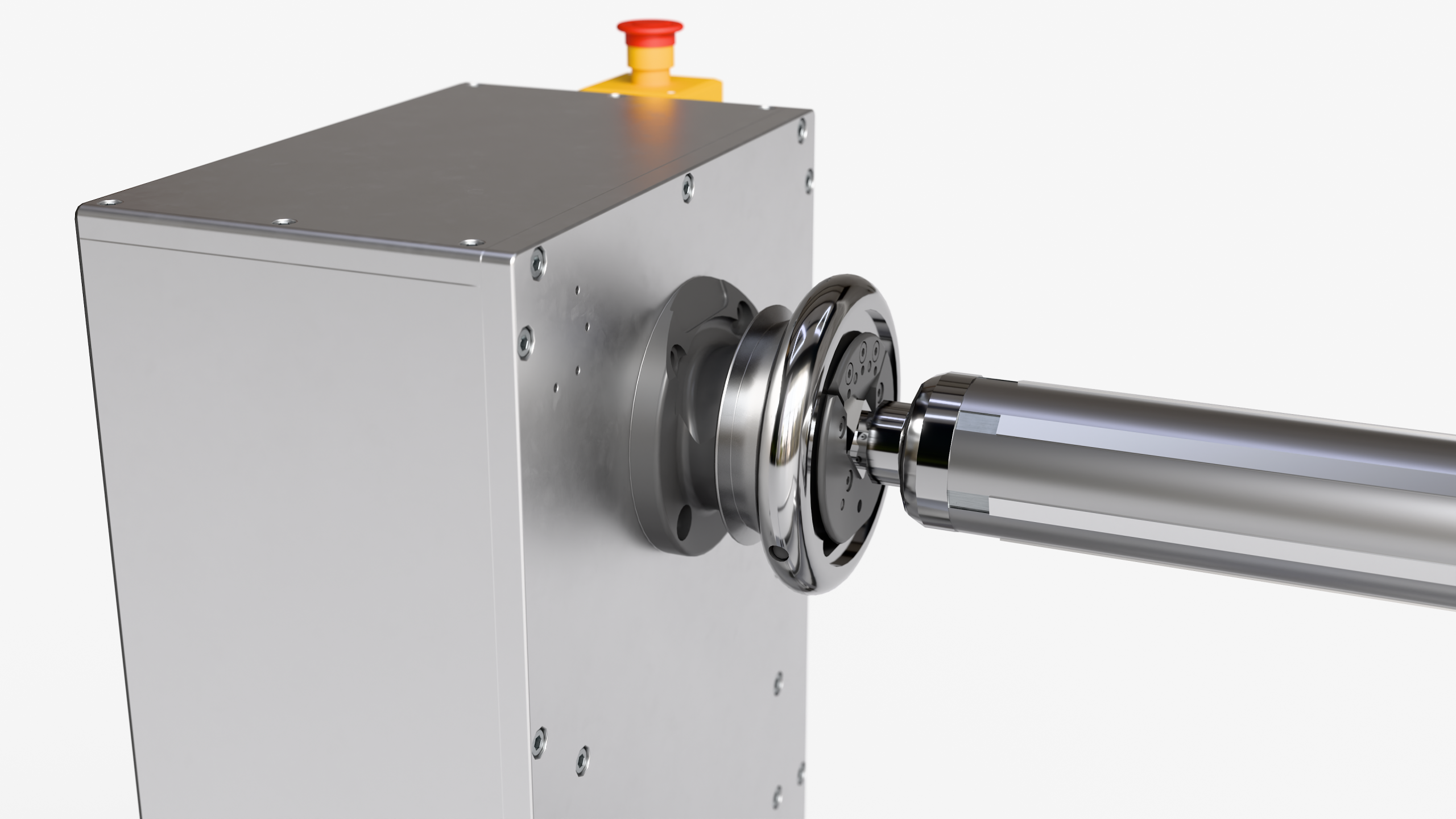

Safety Chucks:

- Fastening by clamping chucks on both ends of the shaft.

- Clamping chucks feature V-shaped jaws for easy and accurate shaft positioning.

Dancer:

- A device that synchronizes the unwinding of the material with the speed of the machine that is receiving the material from the unwinder.

- If the loop is small, the unwinding accelerates to release more material.

- If the loop is large, the unwinding slows down to prevent excessive unwinding.

Electromagnetic Brake/Clutch:

- Device enables winding and unwinding with adjustable tension.

- Tension can be set directly from the control panel.

Control Panel:

- Machine operation via touch screen and several analog buttons.

- Automatic programs for material processing according to settings.

- Manual program for basic operations.

- Counting of processed meters and pieces.

Safety Features

- Protective covers

- Micro switches

- Safety elements designed for maximum prevention of hazardous situations during machine operation.

Description of the machine

1. Shaft

- Interchangeable shaft.

- Basic diameter 3 inches (possible to order different diameters).

- Fastening by using fast locking system on both sides.

- The shaft is equipped with a gauge for correct alignment of the material.

1.1. Clamping chucks

- Fastening of shafts by using clamping chucks on both sides of the shaft. Clamping chucks have jaws with “V” shape for easy placement the shaft on correct position.

2. Drive

- Motor, which provide unwinding of the material.

3. Dancing roll

- Device, which synchronize unwinding of the material with speed of the machine, with which is the unwinder connected.

- If the overhang is small, then the unwind will accelerate to release the material.

- If the overhang is large, the unwind slows down to prevent the material from unwinding too much.

4. Control Panel

- Panel used for control of the unwinder.

5. Electromagnetic brake / clutch

- Device, which provide unwinding by using adjustable tension, without loop.

- Electromagnetic brake is adjustable from the control panel.