ATOM FlashCut

Fashion ALL IN ONE

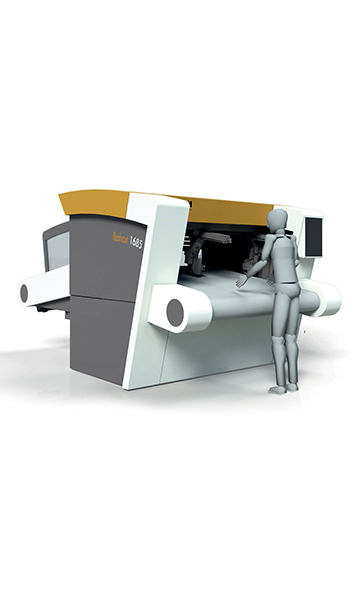

The Flashcut FASHION 26B & 31B is an “All-In-One” models combine processes of acquisition, automatic nesting, and cutting in a single machine.

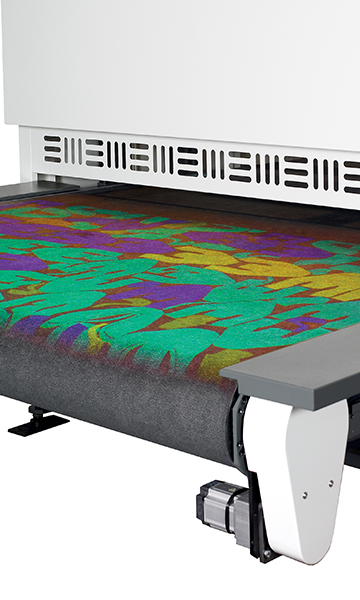

The wide working areas available, with sequential in-line acquisition, automatic nesting, cutting and conveyorized transport cutting belt allow to process and cut from the largest hides to smallest ones acquired simultaneously along the entire width of the machine. The flat working surface, and the perfect parallelism with the knife, supported by a rigid structure, offer homogeneous cutting accuracy and longer life to the transport conveyor belt.

Sequential steps acquisition system allows hides larger than the cutting area to be acquired, but above all, processing hides step-by-step, eases hides inspection, by approaching the area to be inspected by the operator. In addition, it optimizes the processing time, allowing to nest the shapes over the parts already examined. The optical pen allows the operator to easily mark defects and quality areas of the hides and to display them both on the screen & directly on the hide, each one with a particular color. Moreover, Flash Tracer operates as a mouse, able to launch nesting and cutting operations and to modify parameters directly on the working area.

Range - Models

FASHION 16 B

Working Area (MM)

1540 x ∞

Max Absorption (KW)

10,5 / 21,5

Sizes(MM)

2340 x 3747 x 2706h

Description

The brand new model for high production leather cut. High efficiency and productivity for any size of leathers.

Fashion 16 B Floorplan

FASHION 26 B All-in-one

Working Area (MM)

2540 x ∞

Max Absorption (KW)

34

Sizes(MM)

3642 x 3334 x 2275h

Description

To acquire, nest and cut automatically in continuous cycle in a single model. High efficiency and productivity for any size of leathers.

Fashion 26 B Floorplan

FASHION 31 B All-in-one

Working Area (MM)

3120 x ∞

Max Absorption (KW)

35,5

Sizes(MM)

3925 x 3642 x 2349h

Description

To acquire, nest and cut automatically in continuous cycle in a single model. High efficiency and productivity for any size of leathers.

Fashion 31 B Floorplan

Modular Heads

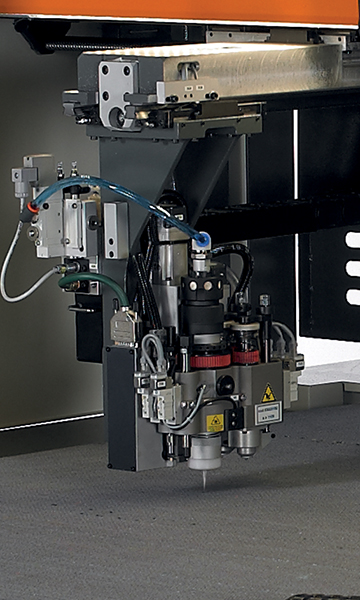

5-Tool Head

The 5-tool cutting head increases the overall versatility of the ATOM Flashcut and is one of the key factor of its success - the ability to total cut, score cut (partial depth cut) & kiss cut with one module, two auxiliary stations that can be equipped with rotating punches for precise small diameter holes, a creaser wheel or kiss cutting knife, a 4th station that includes a marking pen to apply part #’s and trademarks and a 5th non-rotating punch station that is used on light-weight materials. With this versatile head, the Flashcut now becomes a multi-functional production system for a variety of market sectors.

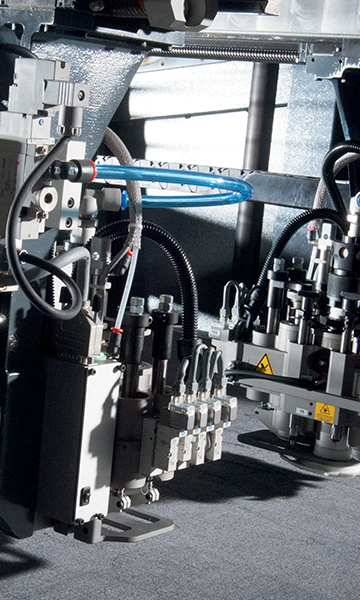

7-Tool Head

The 7-Tool head offers the same combination as the 5-Tool head yet adds two additional rotating punching-drilling stations for increased flexibility. The pneumatically controlled belt-driven punch stations are primarily used for perforating leather, or for punching small diameter holes in gaskets & textile materials. Four independent punch tools on a single head allows for different hole sizes to be produced on the same job. To accommodate different applications, punches are available in sizes ranging from 0.5mm to 8mm & are made from tungsten carbide or high-speed steel (HSS).

5-Tool Head

The 5-tool cutting head increases the overall versatility of the ATOM Flashcut and is one of the key factor of its success - the ability to total cut, score cut (partial depth cut) & kiss cut with one module, two auxiliary stations that can be equipped with rotating punches for precise small diameter holes, a creaser wheel or kiss cutting knife, a 4th station that includes a marking pen to apply part #’s and trademarks and a 5th non-rotating punch station that is used on light-weight materials. With this versatile head, the Flashcut now becomes a multi-functional production system for a variety of market sectors.

7-Tool Head

The 7-Tool head offers the same combination as the 5-Tool head yet adds two additional rotating punching-drilling stations for increased flexibility. The pneumatically controlled belt-driven punch stations are primarily used for perforating leather, or for punching small diameter holes in gaskets & textile materials. Four independent punch tools on a single head allows for different hole sizes to be produced on the same job. To accommodate different applications, punches are available in sizes ranging from 0.5mm to 8mm & are made from tungsten carbide or high-speed steel (HSS).

Tooling Combinations

Side auxiliary tools can include rotating punches/drilling stations, kiss cut tool, creaser wheel for carton stock or thin plastics, or a 45° angle knife. Only available on the 5-Tool or 7-Tool modular head.

Side auxiliary tools can include rotating punches/drilling stations, kiss cut tool, creaser wheel for carton stock or thin plastics, or a 45° angle knife. Only available on the 5-Tool or 7-Tool modular head.

The Drag Knife Chuck (DKC) is ideal for total cutting rigid materials like thin compressed non-asbestos, laminates & plastics up to 6mm (1/4”) in thickness.

The Electric Oscillating Knife Chuck (EOK), is ideal for cutting softer, low-medium density materials like thin foams, soft rubber, pure graphite, leather, laminates, adhesives and similar products.

The pneumatic milling chuck, or PMC, was designed for companies that want the flexibility for light-duty milling applications for rigid materials, primarily plastics (ABS, UHMW, PP, PE etc..), that are not capable of being cut with the traditional pneumatic oscillating knife chuck.

The Pneumatic Oscillating Chuck (POC), is an air driven tool engineered for cutting the most difficult materials but is also used for cutting thick, soft substrates as well.

The Powered Rotary Chuck (PRC), is designed for cutting difficult fibrous materials, both uni-lateral & bi-lateral weaves, at a high rate of speed. The PRC is suitable for processing carbon fibers, Kevlar, fiber-glass, aramid and technical textiles & composites in general.

+PLUS|Flashcut Fashion

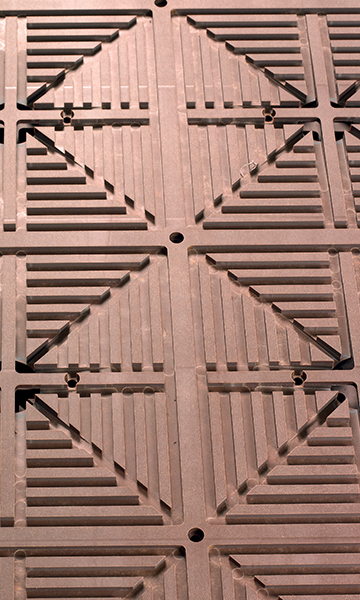

Partitioned Vacuum System

Powerful, partitioned and adjustable vacuum system. Best fixing during cutting and highest energy saving.

High Cutting Accuracy

The perfect parallelism between knife and working surface grants the highest cutting accuracy.

Performance and Reliability

Perfect quality and cutting speed. Accurate mechanic engineering. State-of-the-art electronics.

Optimized Nesting

Customized automatic nesting system. User friendly interface. Reduction of the process times and maximum material yield.

Design and Ergonomics

Original and ergonomic design combining easiness of use and style.

Picking Assistance

Speedy and easy picking of cut pieces thanks to the original software managing the back projectors, allowing to gather parts by size and color.

Acquisition Systems

To speed up the overall time for placing the shapes and optimize skilled manpower.

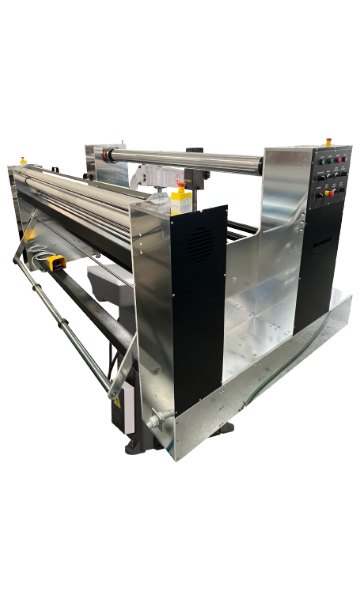

Modular Material

Handling Solutions

Standard & custom engineered material unwinds stands & winders, feeding and spreading machines, sheet-loaders, and in-line loading & off-loading tables.

Downloads

Download FASHION Series Brochure

PDF - 172 KB

Download FASHION ALL-IN-ONE Brochure

PDF - 81 KB