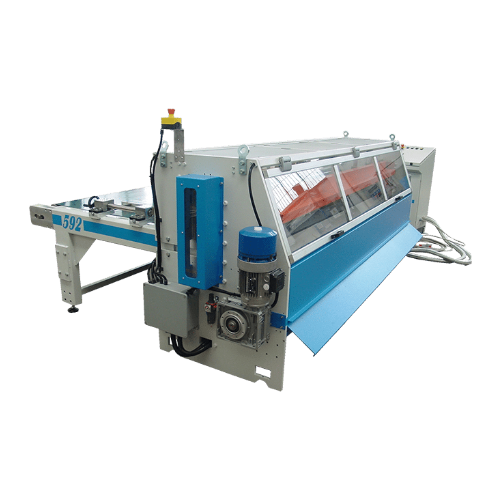

IMESA Model 591/592

Automatic Guillotine Cutting System

The IMESA model 591/592 range of electronic automatic programmable guillotine cutting systems are commonly used for transversally cutting-sheeting materials in both sheet and roll form

The IMESA model 591/592 range of electronic automatic programmable guillotine cutting systems are commonly used for transversally cutting-sheeting materials in both sheet and roll form including coated rubbers & resonated-fabrics, gum rubber, foam & laminated foams, self-adhesive tapes, non-asbestos materials, PTFE, silicone, SBR, PVC, nitrile, polyester, & urethane belting materials, fiberglass & Kevlar fabrics, prepreg & composites, textiles & non-wovens, and similar materials.

Robust construction, designed for extreme reliability, sheeting the hardest materials, the 591/592 series is available in working widths from 800mm up to 2500mm and can successfully sheet products using a shear (upper blade /lower counter-blade) assembly up to 38mm in maximum thickness with extreme accuracy & repeatability.

In addition to the standard machine configuration, the IMESA Model 591/592 transversal guillotine cutting system can be equipped with a variety of auxiliary material handling devices including:

- Cradle Unwinds: Suited for sheeting heavy materials wound in reels without cores.

- Roller Tables: Suited for sheeting heavy sheets of materials. The roller tables are fitted both on the in-feed and out-feed of the slitting line.

- Conveyor Belt Tables: To increase production, primarily for the handling of heavy materials in roll or sheet form, the IMESA shearing machine can equipped with powered in-feed & out-feed conveyor belt tables.

- Powered Unwinds: Designed to unwind the jumbo, & sheet to the desired length. A variety of sizes and features available to handle rolls of materials up to 10,000 Lbs in weight.

- Stacking System: Automatically stack finished sheets on the outboard. Optional indexing conveyor reduces downtime when changing out stacks.

The IMESA model 591/592 can also be installed in an existing production line. The speed of the feeding & guillotine cutting is adjusted with a mechanical or electrical dancer roller according to the end-users production requirements.

The flexibility and strength of IMESA allows them to integrate standard guillotine cutting systems with special equipment engineered & manufactured on demand indicative of the customer’s unique production requirements. All of the IMESA machinery ranges are strictly compliant with the latest European CE safety requirements and the quality as well as the reliability is guaranteed by continuous tests to which they are subjected to at the end of each manufacturing process.