ICZ 1600/2100 E LCA Slitter Rewinder

The ICZ 1600/2100 E LCA is a high-performance machine designed for longitudinal cutting of materials. It features controlled feeding and can be equipped with both an unwinder and a rewinder for efficient material handling.

The ICZ 1600/2100 E LCA is a robust and versatile machine for longitudinal cutting, offering precision, safety, and efficiency. With its advanced control system, adjustable features, and safety mechanisms, it provides a reliable solution for handling a variety of materials.

Key Features

The machine is designed to deliver precision and efficiency in longitudinal cutting operations. It features a controlled material feeding system, allowing for seamless processing. The machine supports optional unwinder and rewinder integration, making it a flexible solution for various material handling needs. With a user-friendly 7-inch HMI touch screen, operators can easily control the machine's settings and functions. Additionally, it includes a CE declaration, ensuring compliance with safety and quality standards, and comes with a comprehensive English manual for easy operation and troubleshooting.

Technical Specifications

This machine is built to handle a variety of materials with precision and durability. It accommodates rolls with a maximum width of 1,702 mm (67'') and an entrance roll diameter of 762 mm (30''). The maximum weight of the entrance roll is 500 kg (1,100 lb), allowing for robust material handling. It can process materials with a thickness of up to 30 mm (1.18''), making it suitable for heavy-duty applications. The ICZ 1600 E LCA operates at a maximum cutting speed of 20 meters per minute (65 feet per minute), ensuring efficiency in production. Furthermore, the machine is equipped with a connector for an exit rewinder, providing seamless integration for further processing.

ICZ 1600/2100 E LCA Slitter Rewinder

Machine Components

Cradle Unwinder

Input Table

The input table ensures smooth material entry into the machine. It is equipped with guiding rails to maintain precise alignment, preventing material shifting during processing. Users can choose between two table options based on their operational needs: a Stainless Steel Flat Entry Table for a firm, stable surface or a Roller Table for smoother feeding of materials.

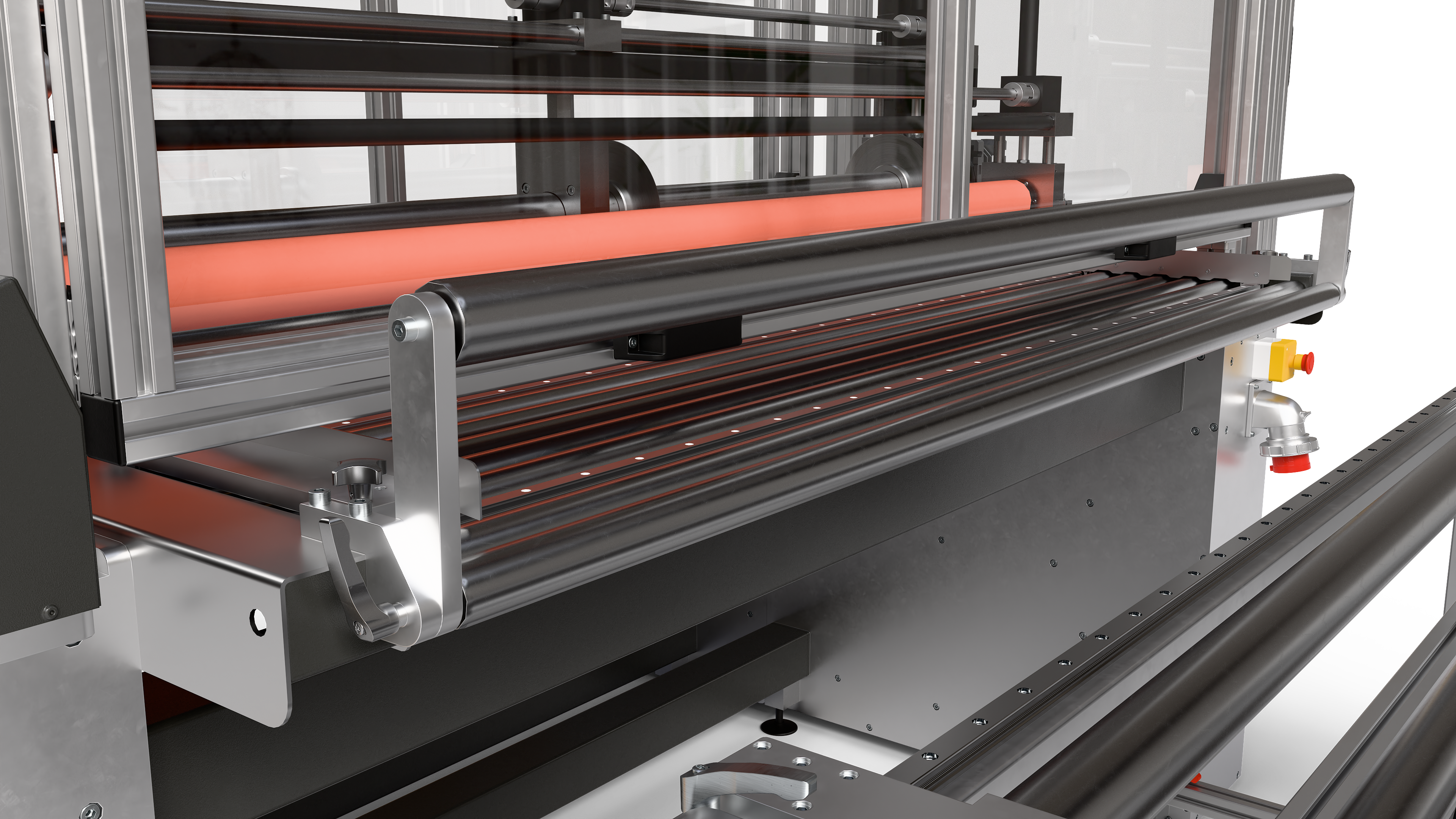

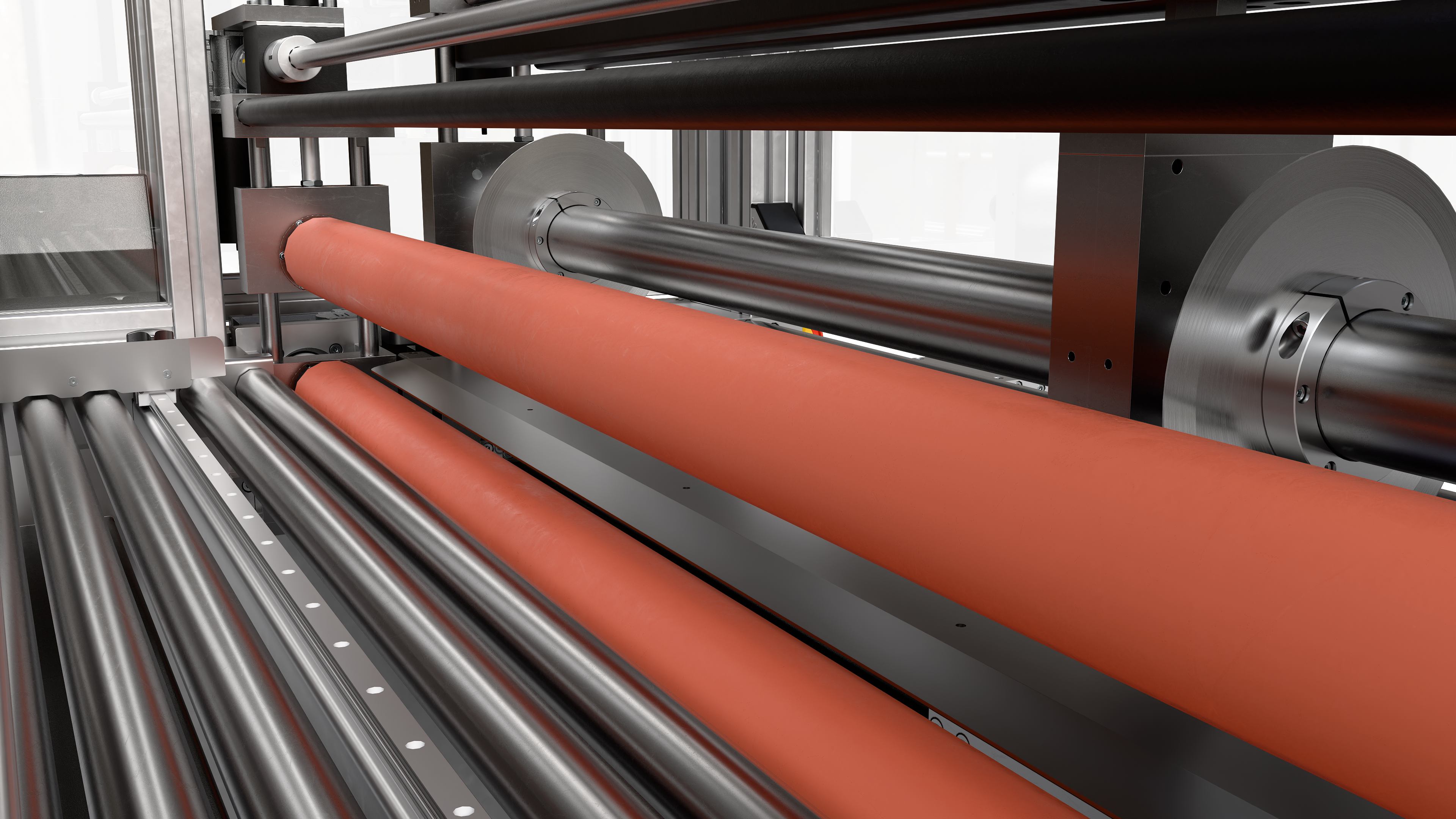

Feeding Unit

The feeding unit ensures a controlled and precise material feed into the machine. It holds the material securely in place during the cutting process, preventing movement that could affect accuracy. This unit also allows operators to set the approximate length of the material to be processed. Featuring a motorized stroke controlled from the panel, it offers smooth operation. The gap between the rollers is adjustable within a range of 0 – 55 mm, accommodating different material thicknesses. The feeding unit consists of two metal cylinders with a special silicone anti-slip surface, ensuring stable and consistent material feeding.

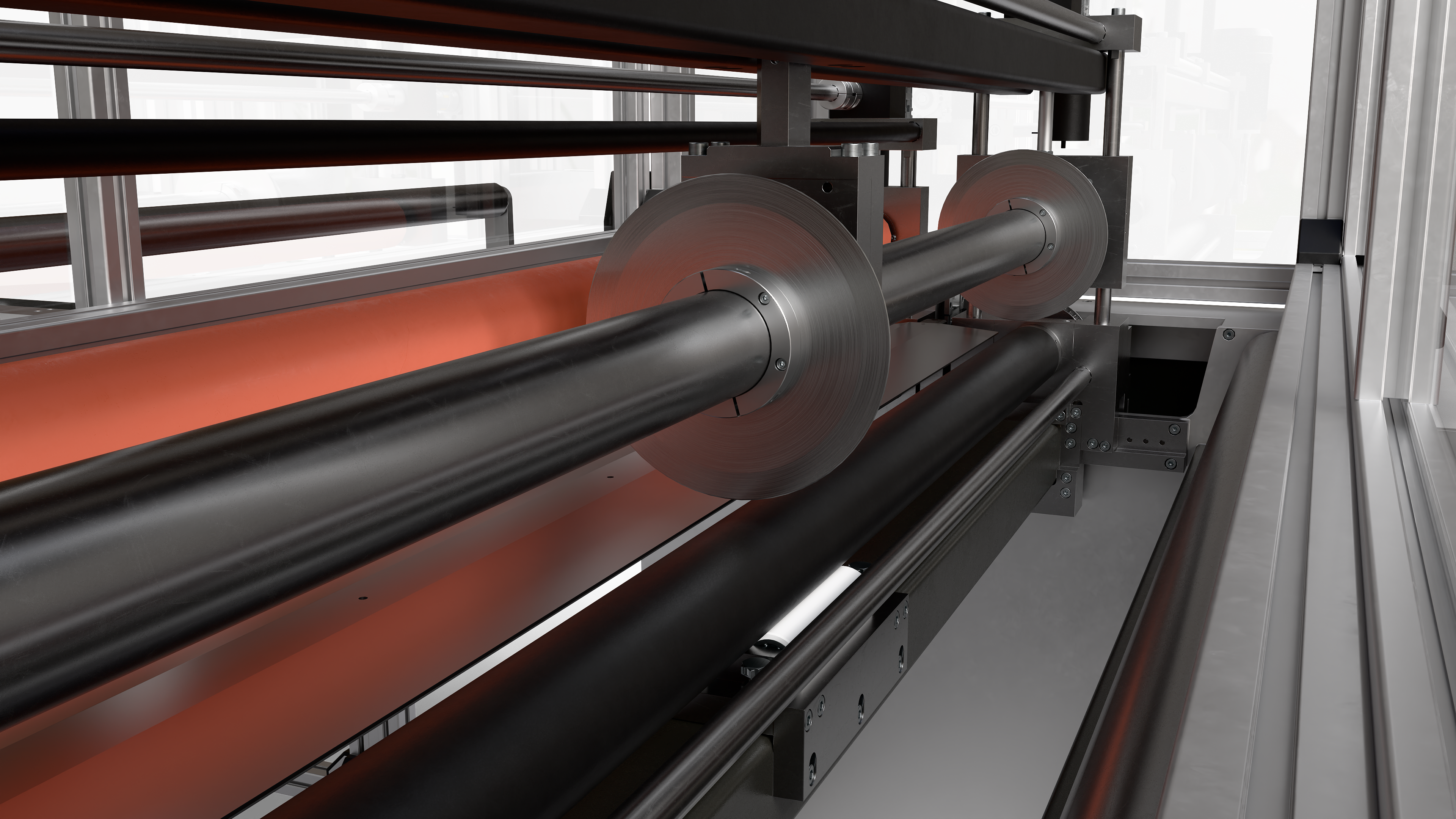

Longitudinal Cutting Unit

The longitudinal cutting unit is responsible for the primary cutting process. It utilizes circular knives with a diameter of 160 mm to achieve precise cuts. These knives cut into replaceable plastic sleeves, which enhance durability and ease of maintenance. The knife shaft is equipped with an adjustable support system to prevent bending, while the lower shaft is reinforced with a central support for added stability. The machine features independent motorized control for both the knife shaft and the shaft with sleeves, allowing for customized speed settings. Additionally, the cylinder gap adjustment is motorized and can be controlled directly from the panel. This unit accommodates materials up to 30 mm (1.18”) thick and 1,702 mm (67”) wide, with a minimum blade distance of 29 mm (1.15”). The unit comes with 10 cutting knives for efficient operation.

External Output Rewinder

The external output rewinder is responsible for winding the processed material. It connects to the machine via a Harting connector and is fully controlled from the machine’s control panel, ensuring seamless operation. The rewinder features an adjustable, controllable torque system for optimal performance. It supports a maximum roll width of 1,702 mm (67”) and a maximum roll diameter of 762 mm (30”). The unit can handle roll weights of up to 500 kg (1,100 lb), provided the roll width is at least 1,000 mm (40”). The rewinder is equipped with a shaft for coreless winding, but it also supports various shaft diameters, including 2”, 3”, 4”, 6”, and 70 mm, offering flexibility in material handling.

Control Panel

The control panel provides a user-friendly interface for managing machine operations. It features a Schneider 7” HMI display, which allows for easy navigation and control of various functions. The panel also includes analog buttons for additional manual control. A recipe-saving feature is integrated into the system, enabling operators to store and recall cutting settings for increased efficiency and repeatability.

Safety Cover

The safety cover is designed to protect the operator and enhance workplace safety. It consists of sturdy covers with plexiglass windows that provide visibility while maintaining protection. Additionally, the system includes microswitches that enhance operational safety and Total Stop Buttons for emergency shutdowns, ensuring a secure working environment.