FEBA, IMESA & ANTARES

SLITTING & REWINDING

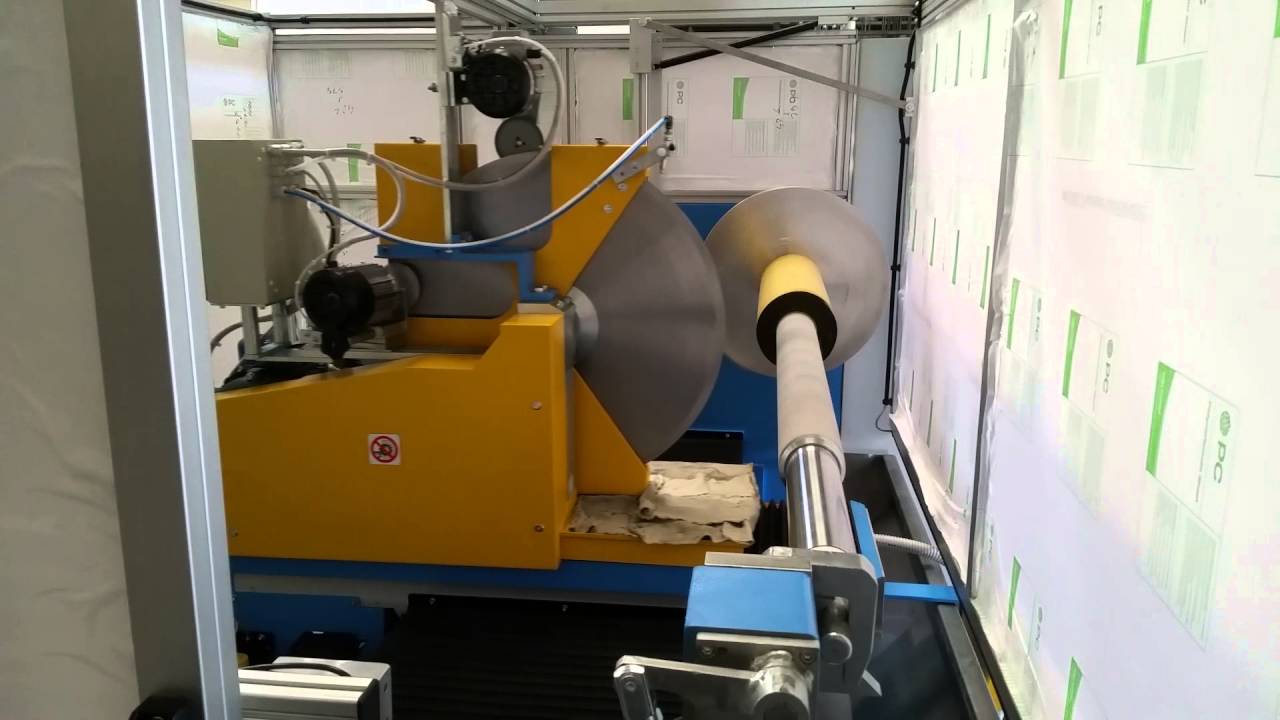

As a leading manufacturers' supply company, we offer a comprehensive suite of cutting and converting solutions through renowned brands like FEBA, Antares, and IMESA. FEBA Converting Machinery Srl stands at the forefront, delivering innovative slitters-rewinders that cater to a wide range of materials, from self-adhesive tapes to flexible packaging. With a focus on customization, FEBA ensures optimal production with features like unwind tension control and in-line packaging solutions, providing clients with exceptional roll quality and efficiency.

Antares, with its extensive history dating back to 1967, specializes in precision cutting machines tailored for industries such as footwear, leather goods, and mechanical sectors. Compliant with CE regulations, Antares' machines offer unparalleled accuracy in cutting materials like synthetics, leather, and rubber. Moreover, their ability to provide bespoke solutions, including roll holders and winders, showcases their commitment to meeting diverse customer needs and delivering precise, reliable performance.