FEBA

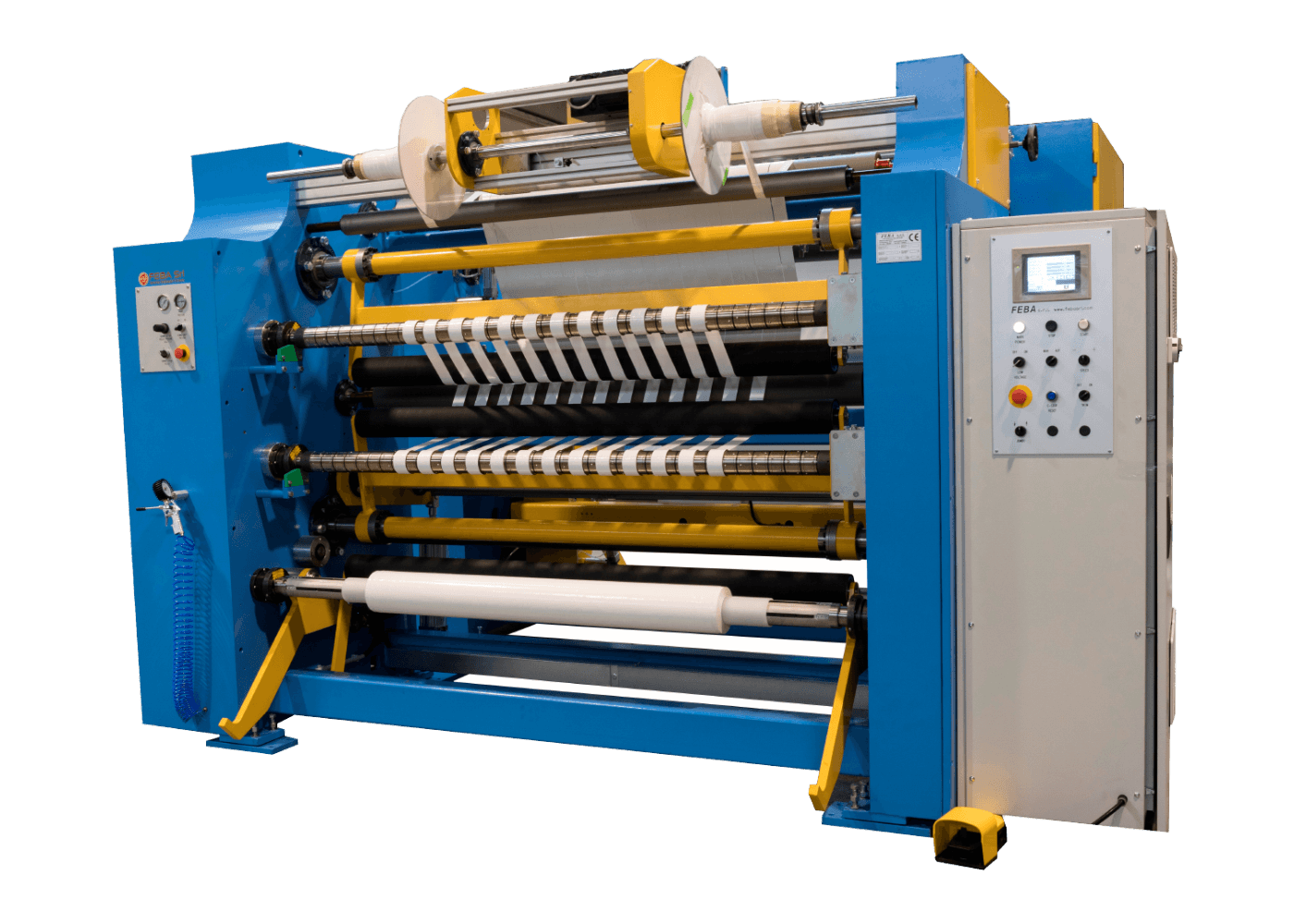

Single Knife Automatic Log Slitters

FEBA Srl Converting Machinery manufactures a complete range of fully automatic single knife log slitters & lathe slitting systems for the adhesive and non-adhesive tape markets, foam and rubber converters, textile manufacturers, producers of foils, protection films, graphite, roofing membranes, paper, laminates & similar products.

FEBA Srl Converting Machinery manufactures a complete range of fully automatic single knife log slitters & lathe slitting systems for the adhesive and non-adhesive tape markets, foam and rubber converters, textile manufacturers, producers of foils, protection films, graphite, roofing membranes, paper, laminates & similar products. All models, from the F400 to the larger F720 & F1000 now each incorporate 3 different levels of specifications with the top levels – SL & EMDS series, providing the ultimate in precision CNC control.

Single Knife Log Slitters

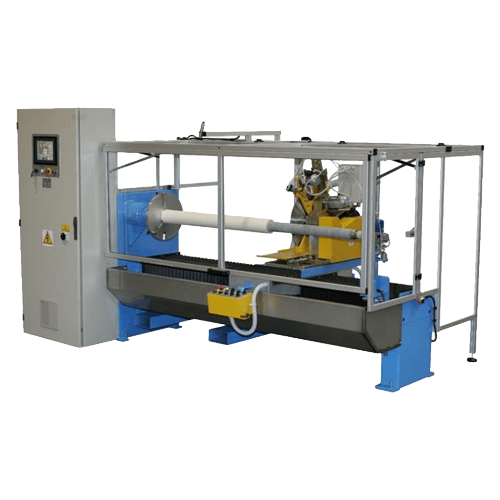

FEBA F400

The FEBA model F400 Automatic Single Knife Log Slitter is the most advanced lathe slitting machine for converters & manufacturers of pressure sensitive tapes, technical tapes, self-adhesive tapes, foam & rubber, gasket & cork materials, graphite, PVC, polyester, polyethylene, protection film tapes, silicone paper & similar products with a maximum outside diameter of 400mm.

| Maximum Material Width | 1200mm – 3100mm |

| Maximum Log Diameter | 400mm |

| Cutting Width | 1-1600mm |

| Cutting Tolerance | +/- 0.1mm |

| Blade Speed Range | 0-1200 RPM |

| Material Speed Range | 0-1200 RPM |

| Core ID | 1”, 1.5”, 2” & 3” |

FEBA F600

The FEBA model F600 Series Single Knife Lathe Slitter is the ideal automatic slitting machine for a variety of small to large diameter materials including adhesive and non-adhesive tapes, self-adhesive tapes, VHB, foam & laminated foams, non-asbestos & cork materials, textiles & non-wovens, rubber, roofing membranes, & similar products with a maximum outside diameter of 600mm (23 5/8”).

| Maximum Material Width | 1650mm – 2200mm |

| Maximum Log Diameter | 600mm |

| Cutting Width | 1-2200mm |

| Cutting Tolerance | +/- 0.1mm |

| Blade Speed Range | 0-1200 RPM |

| Material Speed Range | 0-1200 RPM |

| Core ID | 3”, 4.5” & 6” |

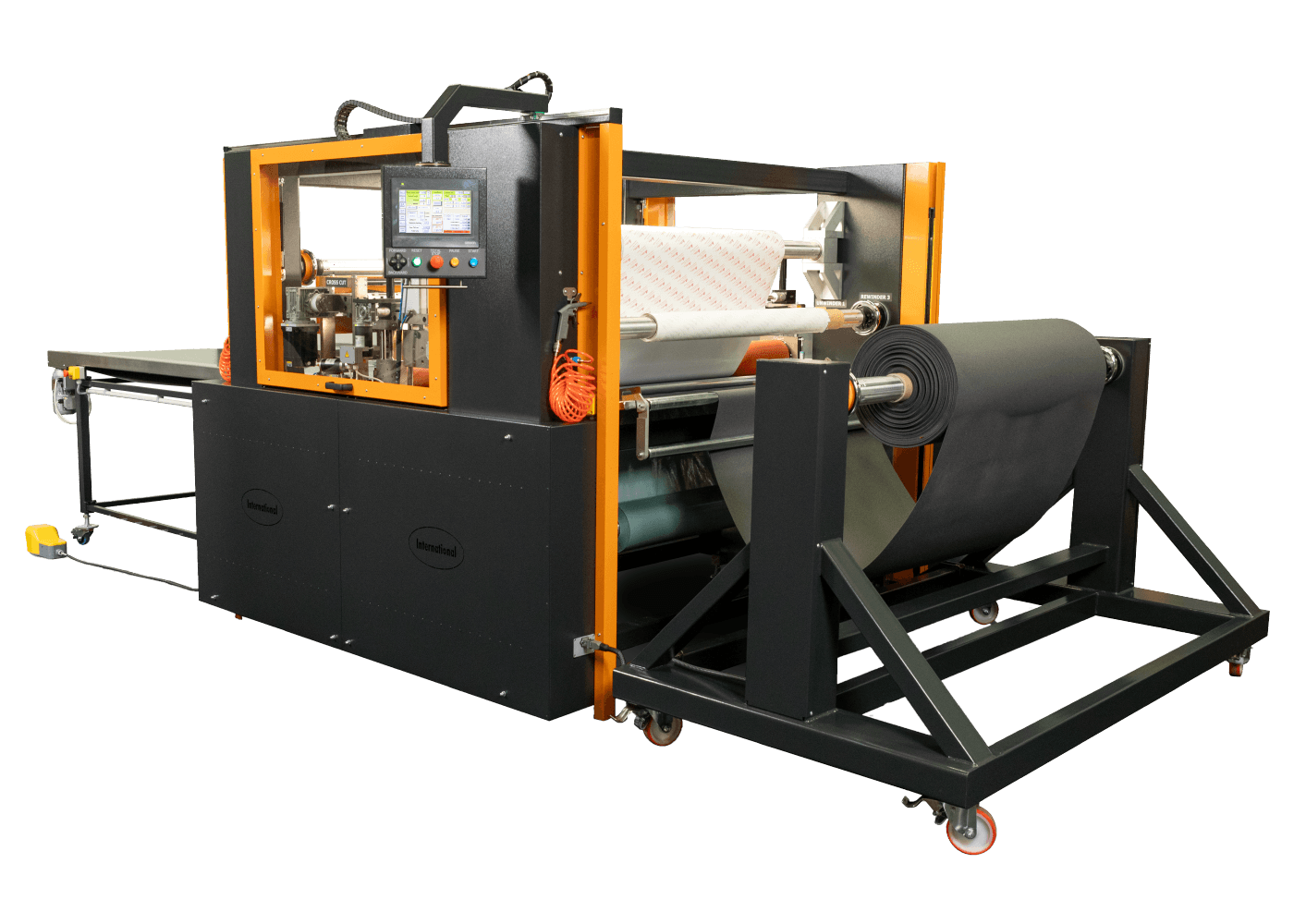

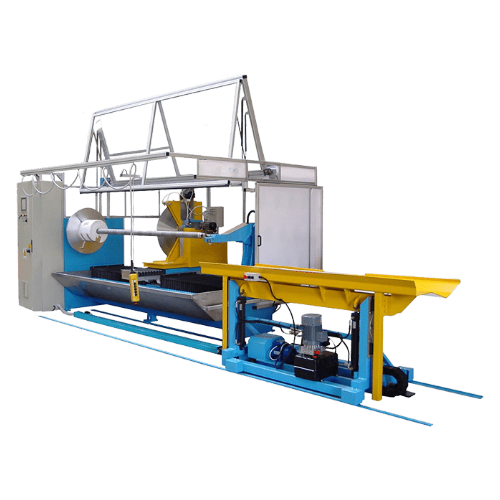

FEBA F720

The FEBA model F720 Series Automatic Single Knife Slitter with the Easy-Load Trolley is the ideal automatic slitting machine for a variety of large diameter materials including foam & laminated foams, textiles & non-wovens, rubber, with a maximum outside diameter of 720mm (28”). In addition, the versatile F720 can be used to slit a wide variety of adhesive and bi-adhesive materials, papers & laminates, films and foils and similar materials in varying diameters and widths.

| Maximum Material Width | 1650mm – 2200mm |

| Maximum Log Diameter | 720mm |

| Cutting Width | 1-2200mm |

| Cutting Tolerance | +/- 0.1mm |

| Blade Speed Range | 0-500 RPM |

| Material Speed Range | 0-500 RPM |

| Core ID | 3”, 4.5” & 6” |

FEBA F1000

The FEBA model F1000 Series Log Slitting System is the ideal automatic single knife slitter for converting large diameter foam materials including PPL foams, PE foams, PVC foams, convoluted foams and similar materials with a maximum outside diameter of 1,000mm (39.5”).

| Working width | mm 1600 – mm 2200 (87″) |

| Maximum Log Diameter | 1000mm |

| Max Ø of the roll | mm 400 (15.7″) |

| Max Ø of the blade | mm 500 (19.6″) |

| Cutting System | Single rotating blade on one mandrel |

| Dimensions | mm. 2650x1350x1320H |

| Weight | Kg. 950 |

The World’s First Truly Automatic Cutting Cycle – FEBA Revolutionizes Lathe Slitting

Having constructed over 2000 various types of slitting & converting machinery for the adhesive tape & general converting industries, FEBA prides themselves in offering their customers the most up to date & technically efficient production machinery. Its strong relations with industrial automation & electronic specialists in the Milan region of Italy have allowed FEBA to borrow a vision from the industrial transportation field (Electro-Magnetic Displacement System) and applied it to the mechanical & electrical efficiency of their lathe slitting line thus effectively removing mechanical servicing & lubrication from the most critical portions of an automatic log slitter.

EMDS actually lifts the slitting head and moves it to the next slitting position, faster than lead screws, without any mechanical inertia what so ever. The EMDS has also been fitted to perform the slitting action (blade penetration) and has been extremely successful on dealing with high density automotive foams at narrow slit widths as well as mid yardage filmic tapes. The newEMDS single knife log slitter now incorporates automatic roll edge acquisition, whereby the operator leaves the machine to automatically find the edge of the log and traverse to the pre-determined trim width. Add to this programmable blade AXIS angles and the new electro-magnetic displacement system (another world’s first which removes the need for lead screws and pistons) and you have the world’s first Truly Automatic Cutting System, without any operator intervention.

Take in to account that, in order to cut the overall cost in lathe slitting conversion, thus increasing profitability, machine users are looking toward Lean Manufacturing techniques that allow one machine to be extremely flexible, handling all blade sizes, log sizes and slit width changes, quickly and efficiently. Having to set any machine manually totally ruins the inherent basis for lean manufacturing and will only have a detrimental effect on production and profitability.

Ideally suited for Lean Manufacturing Techniques, the new EMDS also improves cycle times by up to 35%, removes the need for lubrication of the displacement system and reduces noise, vibration and wear & tear.