IMESA

Shearing Machines

Imesa’s range of shearing machines, equipped with guillotine cross cutting, is designed to achieve high productivity levels.

IMESA Srl Converting Machinery, a 40 year old Italian company based in Vigevano Italy, engineers & manufactures a complete range of multi-blade slitting equipment, automatic sheeting machine & the combination of slitting & transversal guillotine cutting in one system, with working widths from150mm to 3200mm. Their range of slitting & converting equipment are primarily used by companies working in several industries including; heavy rubber, conveyor belting, calendared materials for pipe production, gaskets, textiles, plastics, expanded materials, leather, transportation upholstery and similar fields.

The IMESA machinery range are commonly used for slitting & converting coated rubbers & resonated-fabrics, gum rubber, foam & laminated foams, non-asbestos materials, PTFE, silicone, SBR, PVC, nitrile, polyester, & urethane belting materials, fiberglass & Kevlar fabrics, adhesive tapes & foam tapes, insulation, textiles & non-wovens, and flexible materials in general.

equipped with a variety of auxiliary material handling devices

- Cradle Unwinds: Suited for cutting heavy materials wound in reels without cores.

- Roller Tables: Suited for cutting heavy sheets of materials. The roller tables are fitted both on the in-feed and out-feed of the slitting line.

- Powered Conveyors: In-feed and out-feed conveyors can be fitted for handling heavy rolls of rubber materials. Conveyors can be integrated or independent depending on the application, and in addition, a dancer roll assembly can be fitted to place the slitter in-line with existing equipment.

- Powered Unwinds & Rewinds: Designed to unwind the jumbo, slit to the desired width, and rewind on the outboard. A variety of sizes and features available to handle rolls of materials up to 10,000 Lbs in weight.

- Stacking System: Automatically stack finished cut sheets on the outboard.

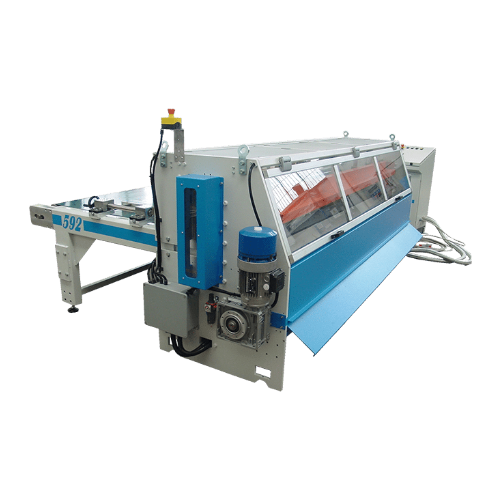

Transversal Guillotine Cutting Systems

The IMESA model 591/592 range of electronic automatic programmable guillotine cutting systems are commonly used for transversally cutting materials in both sheet and roll form. Robust construction, designed for extreme reliability, sheeting the hardest materials, the 591/592 series is available in working widths from 800mm up to 2500mm and can successfully sheet products using a shear (upper blade /lower counter-blade) assembly up to 38mm in maximum thickness with extreme accuracy & repeatability.

MOD 591 Technical data

- Useful material working width up to 800 mm

- Control system with auto-diagnosis of machine main functions

- PLC for managing work programs

- Conveyor system and operation with stepper motor

- Adjustable material conveyor speed

- Pneumatically controlled lifting/lowering conveyor rollers

- Adjustable scissor blade/counter blade cutting group

- Material lateral guides

- Roll holder device

- Safety protection guards in polycarbonate with safety microswitch

- Emergency stop button

MOD 592 Technical data

- Useful working width: 800 – 2500 mm

- Control system with auto-diagnosis of machine main functions

- PLC for managing work programs

- Conveyor system and operation with stepper motor

- Adjustable material conveyor speed

- Pneumatically controlled lifting/lowering conveyor rollers

- Adjustable scissor blade/counter blade cutting group

- Material lateral guides

- Roll holder device

- Safety protection guards in polycarbonate with safety microswitch

- Emergency stop button

Slitting & Guillotine Cutting Systems

The IMESA model 593 electronic automatic programmable slitting & guillotine cutting system is the ideal solution for converting, in sheet and roll form, a wide range of materials & is especially useful in the rubber, insulation, automotive, construction, petro-chemical, conveyor belting & textile industries. With this system, it is possible to cut the material lengthwise and transversally cut with a single operation. Solid construction, engineered for extreme reliability, slitting & sheeting the most difficult materials, the 593 slitter-sheeter is available in working widths from 800mm up to 2500mm and can successfully slit using a blade & counter-blade configuration or a pressure cut (air score w/ anvil) system and sheet products using a shear (upper blade /lower counter-blade) assembly up to 38mm in maximum thickness with extreme precision & repeatability. The flexibility and strength of IMESA allows them to integrate standard slitting systems with special equipment engineered & manufactured on demand indicative of the customer’s unique production requirements. All of the IMESA machinery ranges are strictly compliant with the latest European CE safety requirements and the quality as well as the reliability is guaranteed by continuous tests to which they are subjected to at the end of each manufacturing process.

MOD 593 Features

- Pneumatically controlled lifting/lowering conveyor rollers.

- Length check operated by encoder.

- Shear-cutting system with electronic measurement settings.

- Adjustable blade/counter-blade group.

- Adjustable cutting speed from approx. 0 to 15 m/min.

- Separate control cabin.

- Control system with auto-diagnosis of machine main functions

- Safety protection guards in polycarbonate with safety microswitch.

- Emergency stop button

- Tilted surface for cut piece output.

593

- Roll holder arms, with steel tube and 2 flanges.

- Mechanical brake for material tension adjustment.

- Manually positioned slitting system using circular blades.

- N° 05 diam. 160x70x2HSS circular blades.

- N° 05 blade holders.

- Lower counter roller device.

- Manually-operated blade shaft lifting device.

- Adjustable material guides

- Conveyor system operated by stepper motor