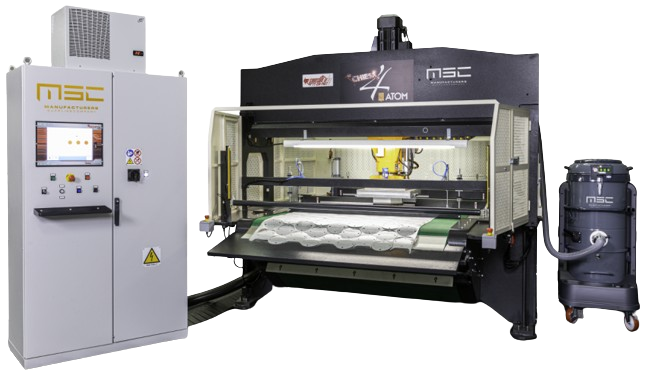

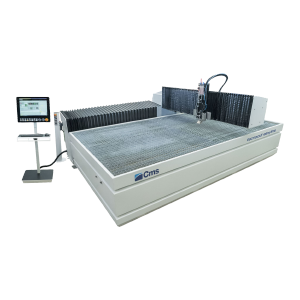

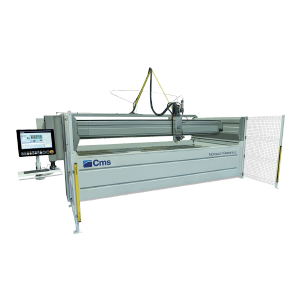

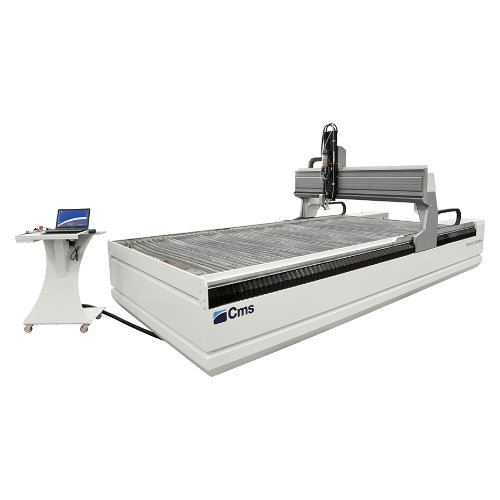

The Complete Solution in Waterjet Cutting Technology

Tecnocut is a leading manufacturer of complete waterjet cutting systems. Tecnocut is the only manufacturer in Italy, and among the few in the world to engineer and develop everything internally. Three basic components: ultra-high pressure intensifiers, cutting robots and highly sophisticated software.

Tecnocut’s product line and technology is especially attractive for companies seeking in-house waterjet cutting capabilities requiring highly productive cutting solutions for the manufacture of products made from soft materials such as rubber, foam and insulation to the hardest materials like stainless steel, stone, glass & composites. Tecnocut is an industrial partner that can supply complete systems with cost effective cutting performances, thorough training, applications advice and post-sales technical support.

How a Waterjet Works

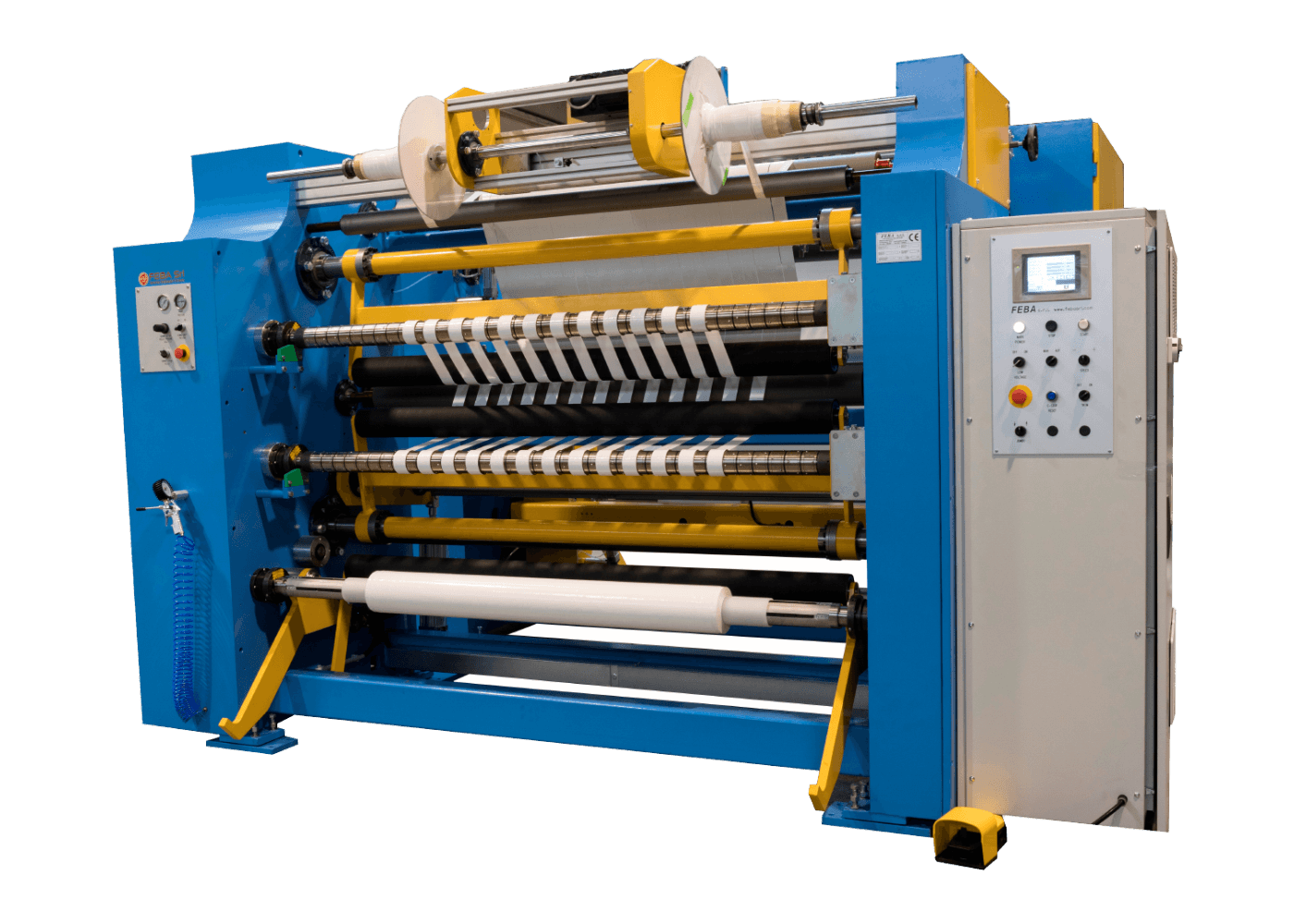

Waterjet cutting is a technology that uses a jet of water at very high pressure (up to 7,000 bar) to cut many types of materials. The energy necessary for cutting is obtained by concentrating through a calibrated hole, a flow of water up to a pressure of 413.7 MPa (60,000 psi) which produces a coherent jet of water projected at twice the speed of sound. The jet, which can be abrasive or not, by reason of the material to be cut, is directed against the surface of the work piece and determines the separation of the parts through a dual action: the combined erosion and abrasion.

The pressurized water is carried out by a special pump hydraulically actuated referenced as “ultra high pressure intensifiers,” the heart of waterjet technology, allowing for a high quality cut, fast and accurate processing of all materials, even long complex shapes, generating the cut surfaces that have an exceptional surface finish and free from any processing residue.

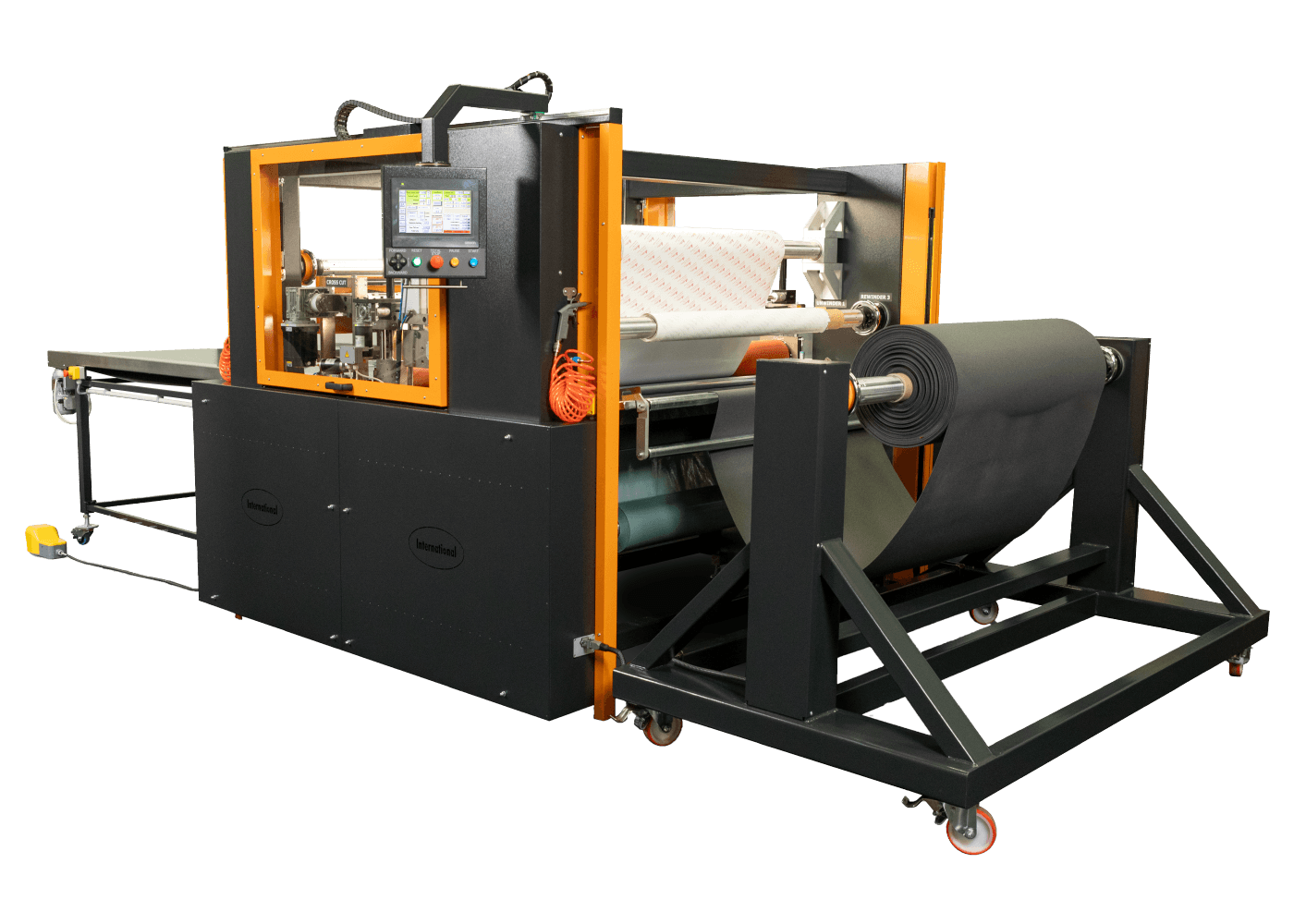

Why Waterjet ?

Waterjet cutting offers many unique abilities over other CNC cutting methods such as EDM, laser or plasma. These features include the ability to cut virtually any material to thicknesses over 12”. Waterjet technology reduces the waste of material removed for the separation of the parties and facilitates the operation of sheet optimization (nesting). There are numerous advantages with this technology: immediate implementation times, because with it you can go directly from design to manufacture and allows you to manage even small batches regardless of the type of material.

It is clear that the use of Waterjet technology can be beneficial in the processing of materials in which any thermal or mechanical stress may compromise the physical-chemical characteristics. Water jet technology is absolutely non-polluting: the absence of fumes or dust ensures a comfortable, risk free working environment. In addition, waterjet cutting can produce remarkably complex cuts with up to 5 axes of motion (3D components), produces high depth to diameter ratio through holes that won’t damage threading taps and can achieve high accuracy parts while being able to obtain almost square inside corners.

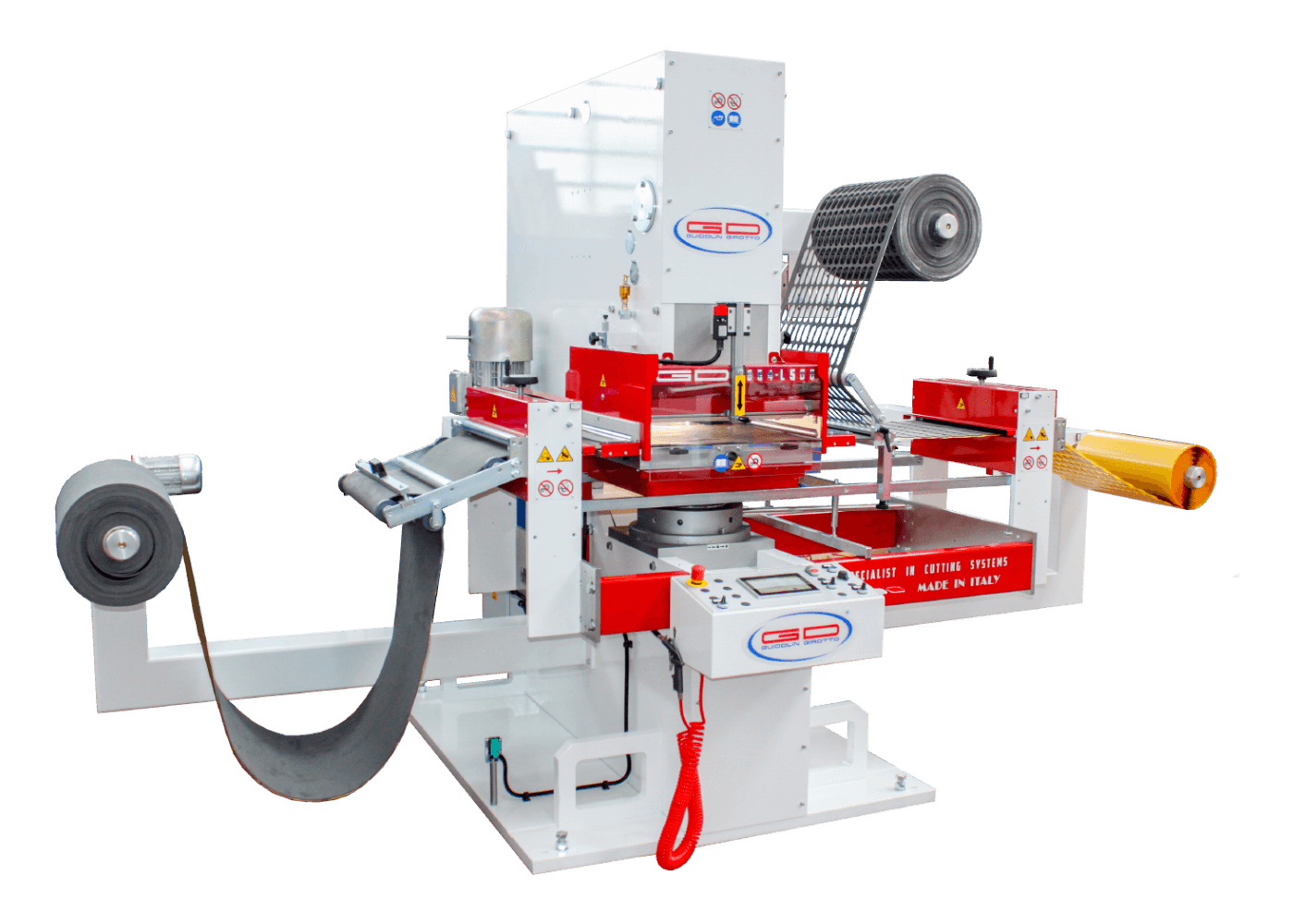

Waterjet Cutting Solutions – Pure Waterjet or Hydro-Abrasive Waterjet

Tecnocut machines are designed to operate both as a pure and abrasive waterjets. A pure waterjet cutting system is used to cut soft materials, and within a couple minutes, the same waterjet can be transformed into an abrasive waterjet to cut hard materials.

Pure waterjet cutting

Pure waterjet cutting is typically used to cut materials with low and medium density and hardness; basically everything you could cut with a pair of scissors. These materials include foams, rubber & synthetic rubber, gasket materials, insulating & sound absorbent materials, textiles, felt, carpet, Kevlar, plastics and flexible materials in general.

Abrasive waterjet cutting

Abrasive waterjet cutting is different from pure waterjet cutting in just a few ways. With the abrasive waterjet, the waterjet stream accelerates abrasive particles and the abrasive, not the water like a pure waterjet, actually cuts the material. The abrasive waterjet is more powerful than a pure waterjet and is capable of cutting high density hard materials. These materials include metals (stainless steel & generic steels, iron, aluminum, copper, titanium, silver, etc..), glass, composites, hard rubber, printed circuit boards, carbon fiber, stone materials & similar products.

Tecnocut’s focus on technological innovation, performance & reliability has made it a worldwide leader in high performance waterjet cutting systems. In addition to its full range of standard waterjet cutting machines and high pressure intensifiers, Tecnocut also offers advanced CAD/CAM software solutions and custom systems.