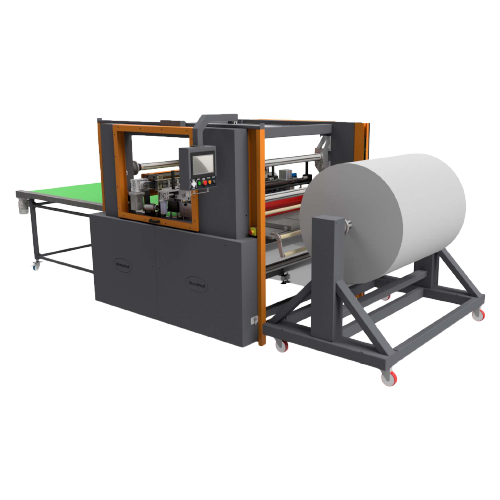

International ICZ 5H

Laminator

Machines designed for lamination using heat-activated or cold adhesive materials up to a thickness of 100 mm and widths of 1300, 1600, and 2300 mm. The machines serve for laminating, rewinding, and cutting materials with the option to wind a protective adhesive layer before lamination.

Machines designed for lamination using heat-activated or cold adhesive materials up to a thickness of 100 mm and widths of 1300, 1600, and 2300 mm. The machines serve for laminating, rewinding, and cutting materials with the option to wind a protective adhesive layer before lamination. Each operation can be performed separately or together. The machine is equipped with a foot switch, which facilitates work on the machine. The maximum processing speed of the material is 20 m/min. The machine is designed with the highest regard for operator safety, and all hazardous parts are covered during operation. The machines are manufactured with a modular structure and can be adjusted based on requirements of the customer.

Options

- External unwinder + machine + output conveyor

- External input conveyor + machine + output conveyor

- External unwinder + external input conveyor + machine + output conveyor

- External unwinder + external input conveyor + machine + output conveyor + external winder

Wide variation of ICZ 4H Laminators

| Type of the machine | working width of the machine |

| ICZ 1300 5H | 1 300 mm |

| ICZ 1600 5H | 1 600 mm |

| ICZ 2300 5H | 2 300 mm |

Units inside of the machine

Lamination unit

- Rolls with rubberized surfaces.

- Possibility to set the temperature of individual rolls up to 100°C.

- Adjustable gap between rolls from 0 to 100 mm.

- Material processing speed from 0 to 20 m/min.

Unit of longitudinal cut

Pneumatic knives

- Cut against a hardened roller.

- Option to choose the number of knives.

- Knife pressure is pneumatic.

Round blades

- Cut against rubber covers on the roller.

- Rubber covers can be easily replaced when worn out.

- Adjustable blades height.

- Option to choose the number of blades.

Puller

- Device designed for material tightening between units.

- Prevents material slippage.

- Used for material movement inside of the machine.

Transverse cutting unit – Cross cut

- Possibility to use a pressure bar.

- Cut performed by a circular rotating knife.

- Possibility to set knife lubrication and sharpening.

- Adjustable sheet length.

Rewinders

- Adjustable material tightening force.

- Adjustable speed for tightening of material.

- Two rewinders in the machine.

- Maximal material weight 100 kg.

- Maximal material diameter 600 mm.

- Swing-out shaft with a ruler for easier material alignment.

- Shaft placed in a swing-out chucks.

- Clamp for 3″ cores.

Unwinders

- Adjustable brake force for unwinding.

- Adjustable speed for tightening of material.

- Two unwinders in the machine.

- Maximal material weight 100 kg.

- Maximal material diameter 600 mm.

- Swing-out shaft with a ruler for easier material alignment.

- Shaft placed in a swing-out chucks.

- Clamp for 3″ cores.

Entrance table

- It serves to guide the material into the machine.

- Ensures consistent material entry angle.

- Prevents material ripple before lamination.

- Possibility to tilt the table.

External Unwinder

- Clamp for 3“ cores.

- Maximal material diameter 1200 mm.

- Maximal material weight 800 kg.

- Shaft with a ruler for easier material alignment.

- Shaft placed in a swing-out chucks.