IMESA

Laminators & Laminating Systems

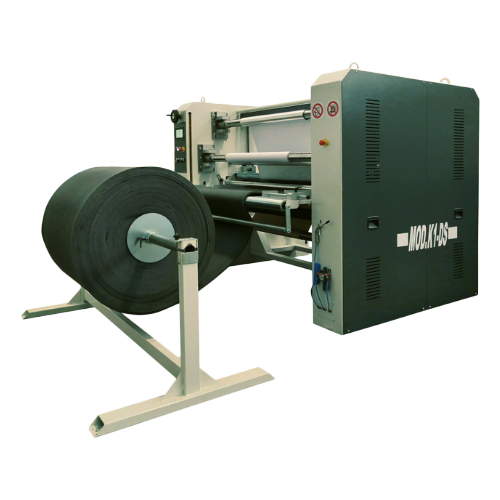

K1 S & DS Laminator

The IMESA K1 DS Double Sided Laminating System is the ideal laminator to applying self-adhesive papers or films to both the top and bottom of various materials including foams and rubbers, adhesive & non-adhesive tapes, foam tapes, fiberglass, non-wovens, technical textiles and similar materials. The version K1 DS main advantages over the K1 Easy Laminator is the ability to apply an adhesive transfer tape to both sides of foams or flexible materials in both roll and sheet form. In addition to featuring a second unwind for adhesive film; the model K1 DS also incorporates a second tension controlled winder for rewinding the adhesive protective liner. Additional features include a second heated nip roll (top and bottom heated) and more accurate tensioning controls for elastic or thin foam materials.

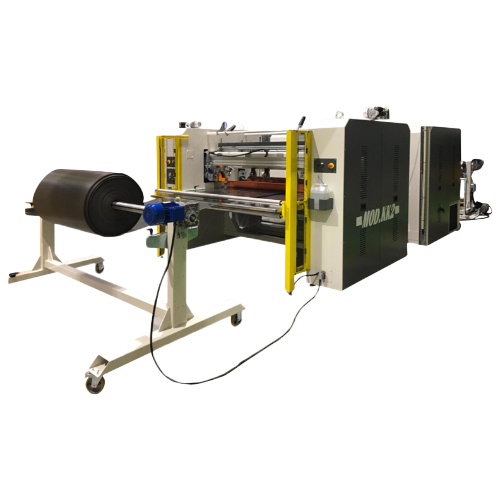

KK1 Laminating Systems

The IMESA KK1 Laminating System combines the ability to laminate adhesive and self-adhesive tapes to both the top & bottom of foams materials along with in-line slitting & sheeting capabilities. IMESA offers a wide range of material handling solutions including center & surface unwinds, web guides, various tensioning control devices, sheet handling, center & surface winders, & accumulators. For heat activated adhesives, the IMESA Laminator can be equipped with infrared preheaters and infrared heated calendars.

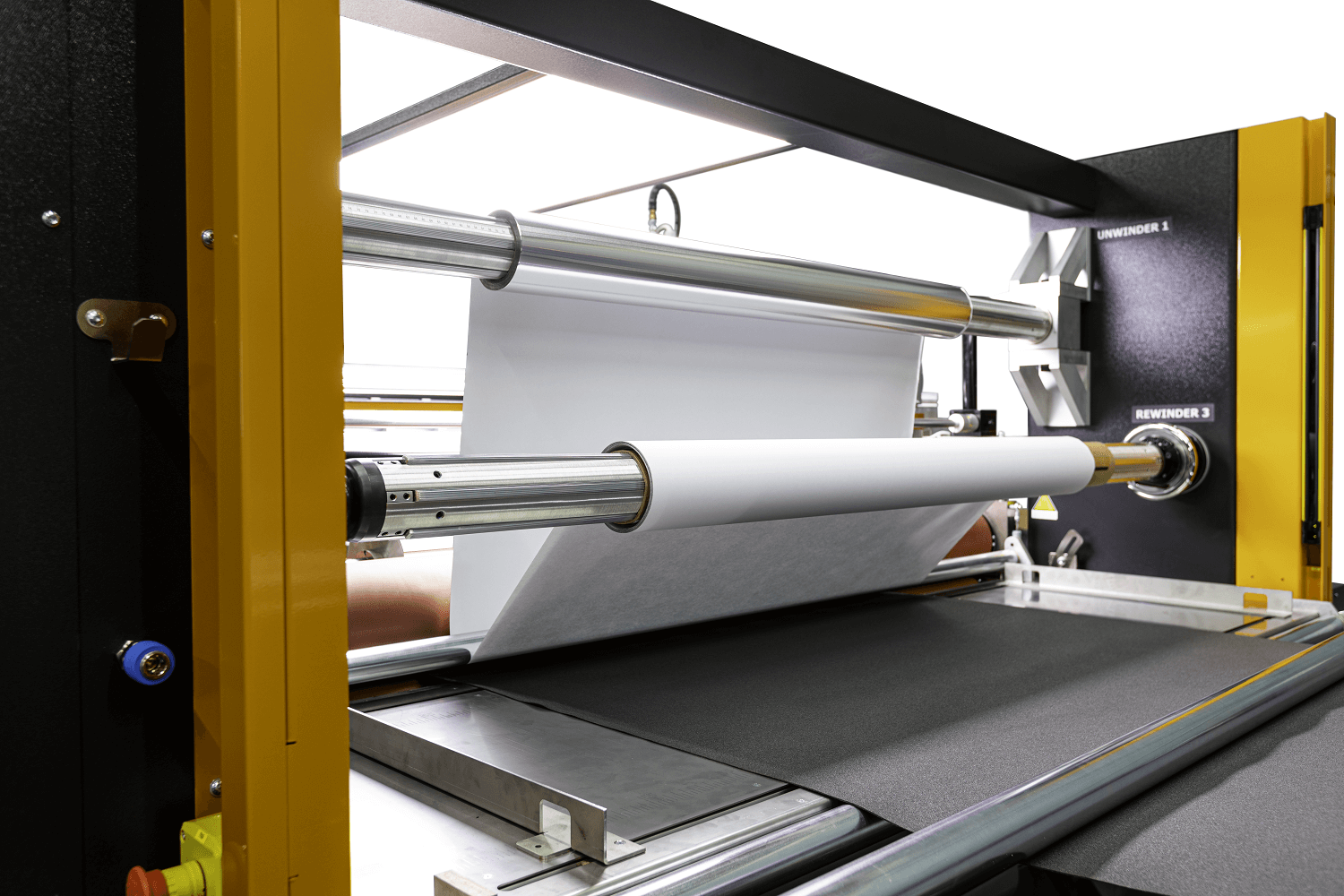

Model K1 Belt

The K1 Belt is specifically designed for sheet-to-sheet applications. It can laminate materials onto foam or other materials such as rubber, melamine, EPDM, polypropylene, polyethylene, polyurethane, etc. Thanks to the special material conveyor system, it ensures optimisation of all sheet-to-sheet applications, integrating them with slitting or cross cutting systems. Depending on the applications and materials, contactless sensors are also available to detect the presence, thickness and colour of the sheets.

Mod K2

The IMESA KK2 Multi-Layer Laminating System combines the same advanced features as the KK1 series but also lamination capabilities to manufacture custom composites from a wide variety of foams and other materials using hot melt films and pressure-sensitive adhesives. These materials include, but are not limited to, open and closed-cell foams, woven textiles, films, coated fabrics, rubber, cork, adhesive & non-adhesive tapes and other specialized materials.