Software

Nesting Software

The ATOM CNC digital knife cutting systems can take advantage of powerful nesting software both automatic and interactive in order to maximize the productivity of the operator as well as the material yield.

Benefits at all levels of company

Management

Based on historical data, it can perform economic analyses on costs, material usage, and consumption.

Production director

You can have all the data relating to the operation of the machines (what they produced, in how much time, how much material they used) to better plan the work.

Line Manager

It can monitor the operating status of all machines and the overall production progress. The system supports him in distributing work among various machines.

Modeling and design

CAD systems are directly connected to the machines' information system to be able to prototype parts quickly.

Machine operator

In addition to having control over the correct functioning of the cutting system, the operator is freed from the burden of programming the work and has a real-time overview of the progress of daily production.

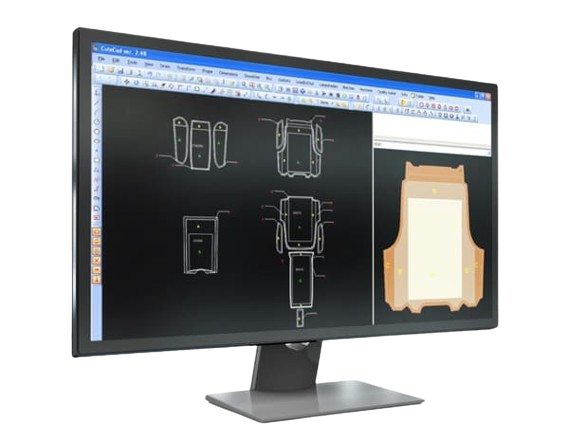

Design software

CuteCad

CuteCad is the 2D CAD software designed for all users. No previous experience is required to get started. CuteCAD is designed with modularity, extensibility and portability in mind, to speed up the prototyping process and reduce the time to market of your products.

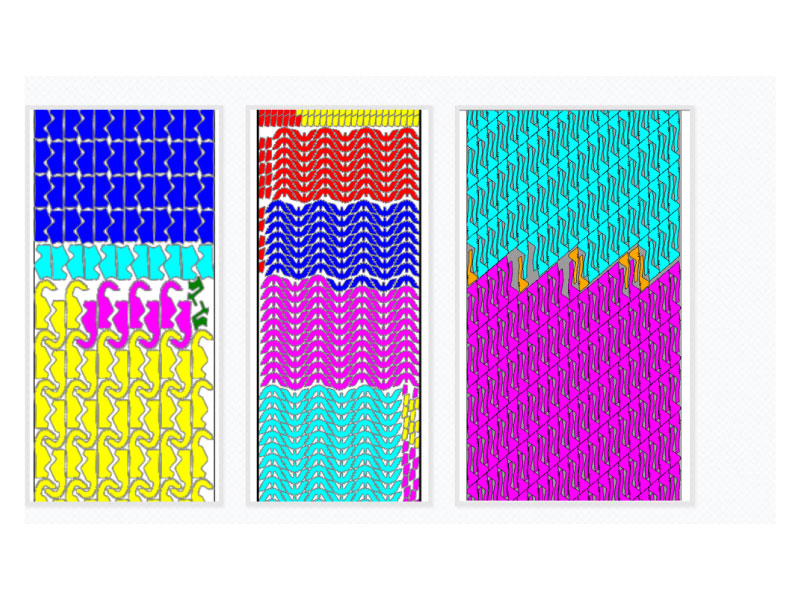

Nesting Systems

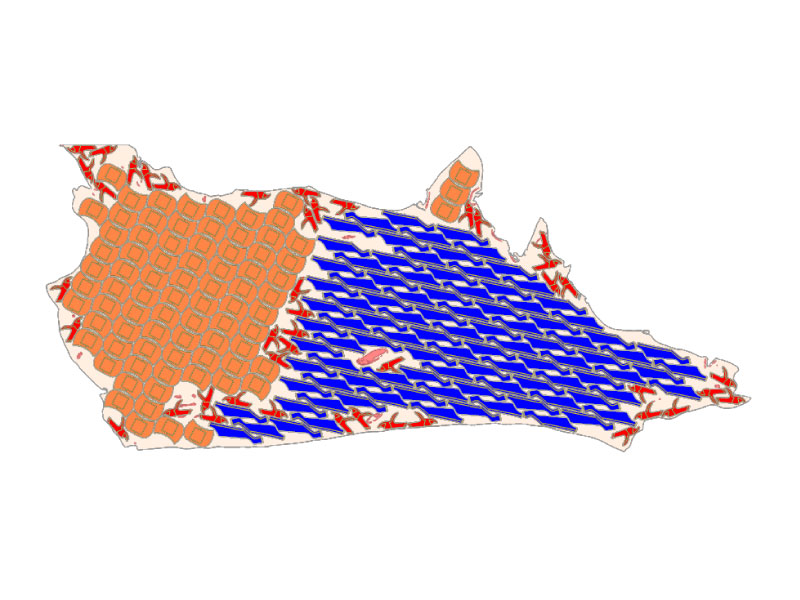

Our Nesting strategies are based on a high-level logic that drives optimization processes using low-level nesting functions, to maximize efficiency and meet each customer’s requirements. We develop specific nesting strategies based on the individual production need: here are some examples

EagleNest

EagleNest - for footwear on synthetic materials

EagleNest is a nesting product designed to meet the typical positioning requirements of the footwear industry when cutting man-made materials. When EagleNest places lasts, it respects the orientation constraints specified for the material and takes into account the manual labor involved in picking and selecting the pieces after cutting.

EagleNest tends to nest parts of a single shape together, so that it is easier for the operator to collect parts for the same stack of parts. While pursuing this goal, the most important goal is to save material, and EagleNest calculates very compact patterns when nesting a block of parts of the same shape.

EagleNest can easily cooperate with the Atom Flashcut cutting table control software and is best suited for off-line nesting of rolls achieving yields in line with typical cost parameters.

ShoeNest

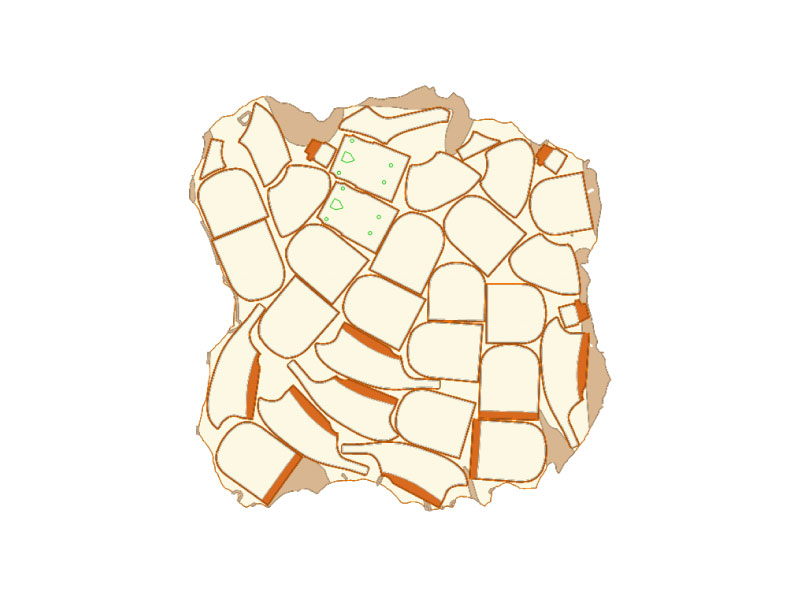

ShoeNest - for leather shoes

ShoeNest is a nesting strategy designed to meet the typical positioning requirements of the footwear industry in leather cutting.

When ShoeNest places lasts, it respects material quality levels and uses lower quality areas and leather defects only for last areas where they are allowed.

ShoeNest naturally tends to place entire items on the same hide and starts with the largest available size and can easily cooperate with the Atom Flashcut cutting table control software and supports both in-line mode (hide acquisition, nesting and cutting are performed sequentially without repositioning the material) and offline mode on previously acquired hides for better yield.

LuxuryNest

LuxuryNest- automotive on leather

Yield optimization is a topic of great interest when it comes to leather cutting. LuxuryNest software is an automated nesting that can be successfully used in both in-line (nesting performed directly on the cutting table) and off-line systems, characterized by two different phases: the marking of defects and the unfolding of the material on the cutting machine

Automatic nesting is parameterized to respect all quality constraints and to obtain the best yield on the available hides.

BagNest

BagNest

Production Control

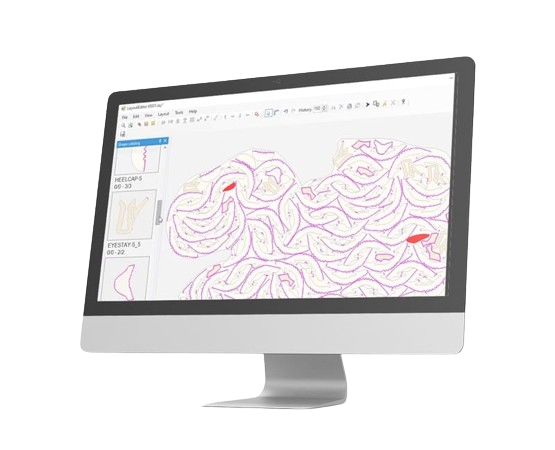

Job Manager

It is the complete solution for the management of cutting rooms, from the smallest to the most complex and structured. It integrates many features in a simple user interface: import orders from ERP, automatic nesting, output to cutting machines and reports from the workshop.

-

Centralized management

It is possible to control through a single database

-

Initial Input

The system provides a large amount of data and the tools to use it. It is able to integrate internal data to the process with external data from other business areas, since it manages all the most popular formats. The Job Manager is also integrated with CuteCad and the Shoemaster platform.

-

Order Entry

Custom automatic import procedures from ERP or external databases can be easily implemented through the development of custom plugins.

-

Complete choice of placement strategies

Atom offers a number of different strategies to suit any type of production. The nesting process is performed entirely in deferred mode, so that cutting layouts are calculated overnight and do not impact production times.

-

Report

Job Manager provides standard reports on order processing and material consumption. Custom report sheets can be provided upon request. All data that is recorded can be made available to business intelligence software for business analysis on material usage, machine usage, production etc.

-

Cutting Room Viewer

Applications to monitor cutting room activities.

For the management of the cutting department – ATOM developed a special software package to create production orders following the given priorities. The JOB Manager software produces various cutting layouts on different materials executing “standard” or customized auto nestings, verifying the yields & material consumption, prior to the cutting process. Finally, it assigns the obtained production orders to the ATOM Flashcut knife cutting machines & collects all the statistical data of the yield & the production time in order to examine the details when requested.

Automatic Nesting Strategies to Optimize Material Yields

- SoleNest – Strategy designed to optimize the nesting of soles on thick leather.

- BagNest – Strategy to nest leather goods such as leather bags, wallets and suitcases.

- BeltNest – Strategy designed to satisfy the makers of leather belts in straight as well as curved shapes.

- UpperNest – Strategy dedicated to the nesting of uppers on leathers used in the footwear industry.

- LuxuryNest – Strategy designed to optimize the nesting of leather used in the upholstery and furniture industry.

- EchoNest – Strategy designed to place shoe components on materials in roll or sheet form – multi-layer materials.

- StripeNest – Strategy aimed @ optimizing the automatic nesting of insoles on material strips.

- TexNest – Strategy to nest on rolls typically used in the apparel & fashion industry.

- SIPECO CAD – Development software for footwear industry – 2D and 3D CAD specific for design, development, shape acquisition, grading and pattern cutting.

- Job Manager Software – For the management of the cutting room – ATOM can supply a special software package to create production orders following the given priorities.

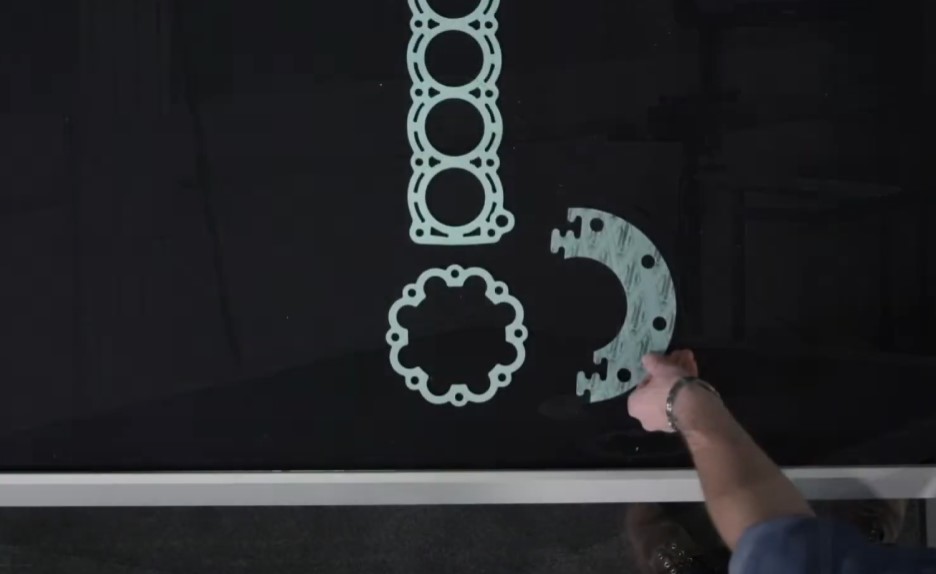

- CuteCAD – The new 2D design software for gaskets designed to speed up the prototyping process and shorten the time-to-market of your products.

* Our customers can also ask for custom nesting solutions able to fully support their production requirements.

+PLUS|Acquisition Systems & Nesting Software

Sequential Acquisition

Sequential steps acquisition system allows the acquisition of hides larger the acquisition area, but above all, processing hides step-by-step, it eases hide inspection., by approaching the area to be inspected to the operator. Moreover, it optimizes the processing time, allowing to nest the shapes over the parts already examined.

FlashTracer Optical Pen

It allows to easily mark defects and quality area of the hides, and to display them both on the screen ad directly on the hide, each one with a proper color. Moreover, FlashTracer operates as a mouse, able to launch nesting and cutting operations and to modify parameters directly on the working area.

Bar Code

After scanning and nesting calculation, the off-line acquisition systems print an identification label with bar code to be applied to leather. Thanks to the label reader, the operator can quickly and easily find the cutting layout which corresponds to the leather processed.

Optimized Nesting

Customized automatic nesting system. User friendly interface. Reduction of the process times and maximum material yield.

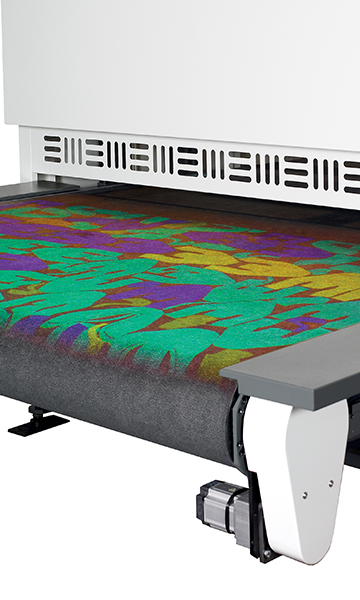

Pre-Printed Materials

The in-line IntelliScan system scans the logo typed materials and coupled with the nesting algorithm, it automatically places the shapes to be cut according to the printed configuration on the materials.

Integrated Systems

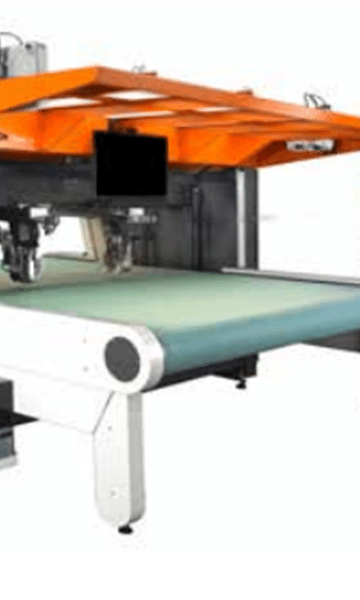

Integrated acquisition systems with ATOM FlashCut knife cutting tables combine acquisition, nesting, cutting & piece collecting in one solution. These “All-in-One” solutions cut operating & labor costs and allow the complete production cycle in one single machine.

Shape Acquisition

Availability of digital scanning systems to automatically acquire pre-cut shapes or sets, eliminate the costly time associated drawing these files in an AutoCAD type software. The system takes a photo of the shape, vectorizes them, automatically corrects optical distortions, and exports data in .dxf or ATOM format ready to be cut.

Downloads

Download

Ring Gasket Layout

PDF - 1.00 MB

Download

Nesting Strategies-1

PDF - 106 KB

Download

Nesting Strategies-2

PDF - 93 KB