Acquisition Systems

ATOM IntelliScanner

The ATOM IntelliScanner Shape Acquisition System is a revolutionary camera digitizing device which is able to automatically acquire the geometric data from cardboard models, paper patterns or pre-cut components.

+PLUS|Acquisition Systems & Nesting Software

Sequential Acquisition

Sequential steps acquisition system allows the acquisition of hides larger the acquisition area, but above all, processing hides step-by-step, it eases hide inspection., by approaching the area to be inspected to the operator. Moreover, it optimizes the processing time, allowing to nest the shapes over the parts already examined.

FlashTracer Optical Pen

It allows to easily mark defects and quality area of the hides, and to display them both on the screen ad directly on the hide, each one with a proper color. Moreover, FlashTracer operates as a mouse, able to launch nesting and cutting operations and to modify parameters directly on the working area.

Bar Code

After scanning and nesting calculation, the off-line acquisition systems print an identification label with bar code to be applied to leather. Thanks to the label reader, the operator can quickly and easily find the cutting layout which corresponds to the leather processed.

Optimized Nesting

Customized automatic nesting system. User friendly interface. Reduction of the process times and maximum material yield.

Pre-Printed Materials

The in-line IntelliScan system scans the logo typed materials and coupled with the nesting algorithm, it automatically places the shapes to be cut according to the printed configuration on the materials.

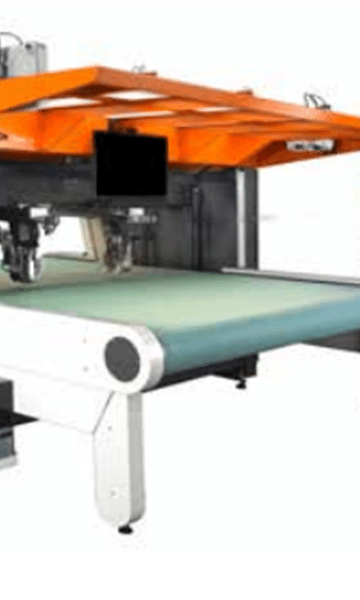

Integrated Systems

Integrated acquisition systems with ATOM FlashCut knife cutting tables combine acquisition, nesting, cutting & piece collecting in one solution. These “All-in-One” solutions cut operating & labor costs and allow the complete production cycle in one single machine.

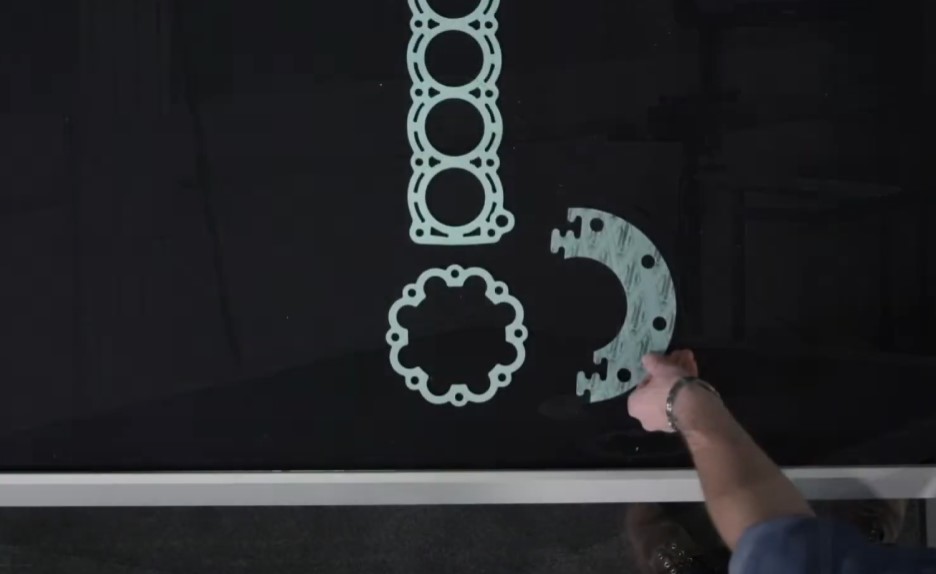

Shape Acquisition

Availability of digital scanning systems to automatically acquire pre-cut shapes or sets, eliminate the costly time associated drawing these files in an AutoCAD type software. The system takes a photo of the shape, vectorizes them, automatically corrects optical distortions, and exports data in .dxf or ATOM format ready to be cut.

Downloads

Download ATOM IntelliScanner Brochure

PDF - 623 KB