- Description

- Technical Specifications

- Modular Stations

- Points of Strenghts

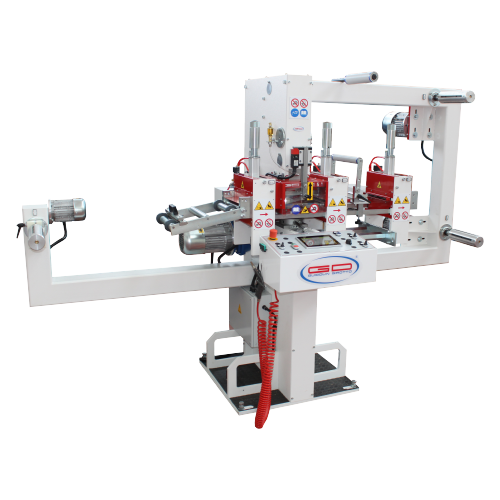

The Guidolin Girotto rotary die cutting machine, model RO EL, is the ideal Entry Level rotary cutting press for converters of neutral and printed labels, laminated foams and textiles, adhesives & double sided adhesive materials. This compact die cutting & converting machine is available in three working widths; 175mm, 250mm and 350mm, and is capable of running at speeds from 0-60 meters per minute. The new EL version employs the same features as the traditional RO series rotary die cutting systems; rigid electro-welded steel frame, modular stations, numerous options and computer controlled system making it extremely versatile, fast & easy to use, assuring rapid changeover which in-turn decreases down time and production costs.

Every station on the EL series is movable with fixed locating pins for quick change station to station and the machine may be purchased with limited options to fulfill current requirements and stations can be added in the future as needed. The single motor and in-line drive shaft with precision worm gears keep the machine simple yet accurate eliminating the inherent problems associated with complex servos and electronics.

The transport and laminating stations have a single adjustment hand wheel screw in the center for easy closure allowing the path rollers to stay completely level – eliminating the wandering of the web – a common problem associated with dual adjustable transports – saving the operator a significant amount of time during set-up. The 4” color touchscreen, with the ability to save parameters for 500 different jobs, can count in distance or parts cut based upon the number of teeth in the gear or cavities in the tool for the precise count of individual pieces or distance traveled. For additional safety measures, the machine will not start until the speed control is set to zero to avoid the crashing of the web or injury to the operator.

High structural quality, accurate die cutting precision, silence, versatility and excellent relation between quality and price are the best representation of our rotary die cutting machines in the world.

Contact us to get Technical Specifications

The RO EL Rotary Die Cutter can be equipped with the following modular stations:

- Single or Double Unwind with Mechanical Friction (Optional Ultrasonic Sensor for Precise Tension Control)

- Lamination System Complete with Guides & Counter-Roll Covered in Anti-Adherent Silicone

- Die Cutting Station with Transversal or Longitudinal Micro-Metric Regulation

- Single Motorized Rewind with Adjustable Bar for Scrap Removal

- Liner Change Assembly

- Slitting System : Razor Blade, Scissor Cut or Pressure Cut

- Outboard Conveyor with Feed Rolls Covered in Anti-Adherent Silicone Rubber.

- Single or Double Rewind on the Outboard Side

Modular Strengths

- Every station is movable

- Gears are worm gears for extra precision

- Fixed locating pins allow for quick change station to station

- Machine may be purchased with limited options to fill current needs and stations can be added as needed in the future

- Off-line trolley to stock the modular stations while not in use.

Simplicity Strengths

- Simple spring clutches, less electronics, less dials for operator adjustment & error

- Single brushless servo motor coupled with an in-line drive shaft and precision worm gears in order to grant the same torque strength from zero to maximum working speed

- Transport and Laminating stations have a single adjustment screw in the center, for easy closure allowing the path rollers to stay completely level – eliminating the wandering of the web – a common problem with dual adjustable transport rollers

Electronics & Software

- Touch screen with the ability to save parameters for 500 jobs

- Operate in both start/stop mode & continuous mode

- Can count in distance or parts cut based upon number of teeth and cavities in the die for precise count of either parts or distance traveled

- Although the desired speed can be saved for a job, the machine will not start until the speed control is set to zero to prevent crashing the web or injuring an operator.

- Sonar to control the tension of the lower unwinds for sensitive materials when needed, controlled in touch screen PLC.

- Automatic web guide system for the automatic alignment of the material with electronic edge guide to grant a constant & suitable alignment of the material with seperate electronic control device for set-up