- Description

- Sectors

- Technical Specifications

- Points of Strenghts

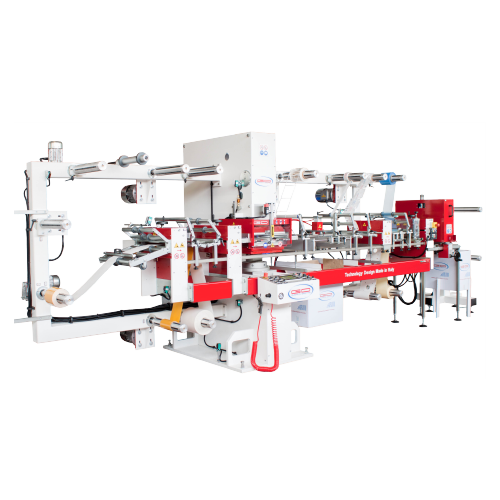

The Guidolin Girotto automated flat-bed die cutting press, model GD 401D, is the ideal automated converting system for converters of pressure sensitive adhesive and double sided adhesives, foams & laminated foams (open & closed cell), converters in the transportation industry (internal gaskets & car emblems), manufacturers of electronic & medical devices, plastics etc.. The 401D high speed kiss cutting machine develops 20 mechanical tons of cutting force, has a cutting platen of 400mm x 400mm, a fixed stroke of 40mm, with speeds ranging from 30-150 strokes per minute.

The traditional architecture and features that qualify the Guidolin product worldwide are employed; robust frame structure, mechanical fly-wheel operation (which eliminates the problems associated with PRECO style 4-post hydraulically operated cutting presses), single cylinder positive stop adjustment for precise cutting accuracy (+/- .01mm), quick die change, ease of use, and modular design.

High structural quality, accurate die cutting precision, silence, power and excellent relation between quality and price are the best representation of our die cutting machines in the world.

The main sectors for our machinery include the following: abrasives, automotive, aerospace, composites, electronics, gaskets, labels, medical, packaging, plastics, & self-adhesive tapes.

In the automotive sector, our customers are direct suppliers of: Alfa Romeo, Audi, BMW, Ferrari, Fiat, Ford, Honda, Mercedes, Mitsubishi, Nissan, Peugeot, Renault, Skoda, Toyota and Volkswagon. In the field of adhesive and double sided adhesive tapes, we work on a global scale with converters of 3M, Tesa, Avery Dennison, Lohmann, Nitto Denko, Scapa and many others.

Our products are developed in close cooperation with our clients starting from the design stage, to reflect the specific needs of their requirements, to increase productivity and optimize material utilization and labor.

Abrasives

- Polishing Pads

- Kiss-cut Discs/Sheets

- Sanding blocks

Automotive

- Car emblems

- Sealing & insulation

- Sound & vibration dampening

- Protection

- Gaskets

- Self-adhesive tapes

Aerospace/Composites

- Protection films

- Kapton

- Laminated foils

- Plastics

- Self-adhesive tapes

- Gaskets & Foam

Electronics Sector

- Protective gaskets

- Bonding circuits

- Surface protection films

- Phone screens

- Optical films

- Self-adhesive tapes

Foams (Open & Closed Cell)

- PU

- EPDM

- Neoprene

- EVA

- PVC

- Silicone

- NBR

- Viton

- SBR

Gaskets

- Silicone Gaskets

- Rubber Gaskets

- Foam Gaskets

- Mylar Gaskets

- Nomex/TNT Gaskets

- Textile & Non-Textile

- Velcro

Labels

- Neutral Labels

- Printed Labels

- Special Labels

- Stickers

- Bar Codes

Medical Sector

- Orthopedic parts

- Velcro

- Felt, TNT & textile

- Non-woven textile

- Foams

- Self-adhesive tapes

- Blood-strips

- Corn Pads

Packaging

- Protection films

- Foams

- Self-adhesive tapes

- Labels

Plastics

- Electronic cards

- Computer components

- Mobile components

- Optical Polishing pads

Self-Adhesive Tapes

- Double Sided Tapes

- Transfer Tapes

- Masking Tapes

- Converters of 3M, Tesa, Nitto Denko, Lohmann, Avery Dennison

Contact us to get Technical Specifications

| Operating Features | Guidolin Girotto Benefits |

|---|---|

| Mechanically Operated | Flywheel & camshaft driven allows the energy from the power source to be supplied at a constant rate throughout the operation. Thus allowing higher cutting power, precision, less set-up and noise- less operation. |

| Single Cylinder Adjustment | Micrometric single cylinder adjustment (+/- .01mm) guarantees perfect platen parallelism & eliminates the problems associated with 4-post hydraulically operated presses – i.e. die board shimming, hydraulic leaks, seal wear & loss of pressure. |

| Quick Die Change | Plate support cutting knife with guides that are dove tailed @ 60° for a quick and easy change of the cutting die. Cutting dies can be changed without removing the material from the machine during the production cycle. |

| Single Nip Roll Adjustment | A single (centered) nip roll adjustment allows for the nip rolls to be set perfectly parallel during the lamination process greatly reducing the time associated during set-up with traditional dual mechanical stop adjustments (left & right). |

| Modular Design | A variety of options are available to automate and customize the system to suit a wide variety of converting requirements. Most options can be added in the future. |

| Industrial PLC | Industrial PLC can store up to 400 jobs for quick set-up. Operational controls can be customized for special/custom converting applications. |

| Vision System – Cut to Print | Various vision (registration) systems are availabile utilizing an optical photocell for reading a notch, printed references (clear, dark, color) & holograms. Registration systems are available for one (X), two (X-Y) and three (X-Y-Z) axes in a variety of accuracy levels. |

| Knock-Out / Part Expulsion | A wide variety of knock out stations are available with registration on the X,Y & Z axes. Centers or scrap can be removed via pneumatic expulsion, vaccum, air etc.. And finished, total-cut parts, can be stacked on a table or conveyor. |

| Guillotine Cutting Systems | Automatic guillotine cutting system assembled on the machine for the transversal cut, equipped with motorized feeding rolls, friction & adjustable on the axes. Equipped on a table with a slide to move out of the way when running roll-roll applications. |

| In-Line Slitting Systems | A variety of in-line slitting systems are available including razor blade, blade counterblade (scissor), & pressure cut (Score) with regulation on the axes. Slitting units can be set-up for total cutting or kiss-cutting applications. |

| Automatic Sheet Loading | Automatic sheet loading device with vacuum pick and place system equipped with a hydraulic lift and optical photocell to register the sheet location. |

| In-Line Printing | A wide variety of in-line printing systems are available for printing on various substrates. |

| Custom Converting Solutions | Custom solutions available for the most challenging converting applications & requirements. |