Chiesa CNC Die Cutting Systems

with MATCHED METAL TOOLING

Chiesa Artorige, the pioneers behind automatic CNC die cutting, and the innovators of the EDI servo driven automatic cutting press, has developed & patented a new technology utilizing matched metal (male/female) tooling for processing a variety of substrates in wide web formats.

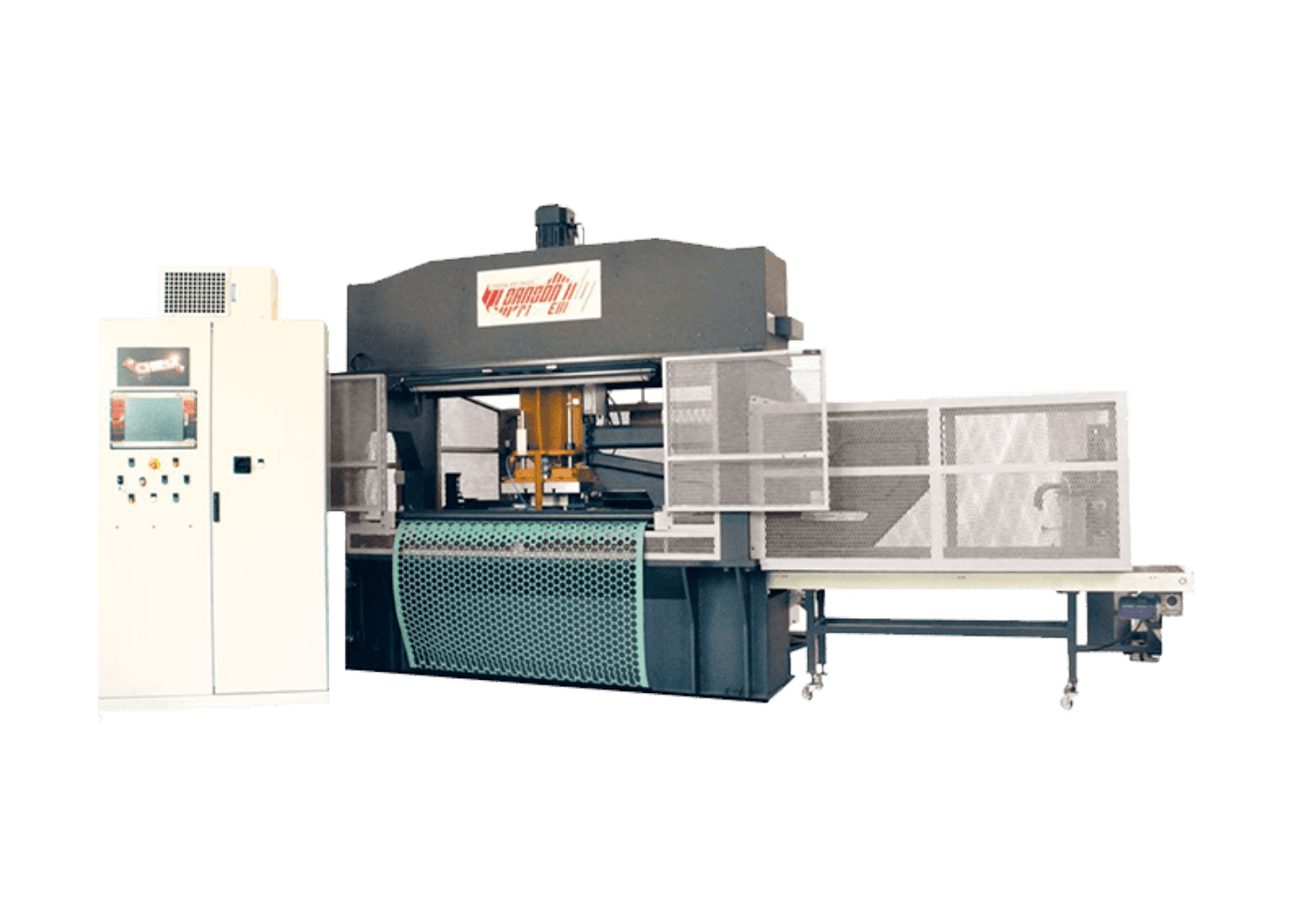

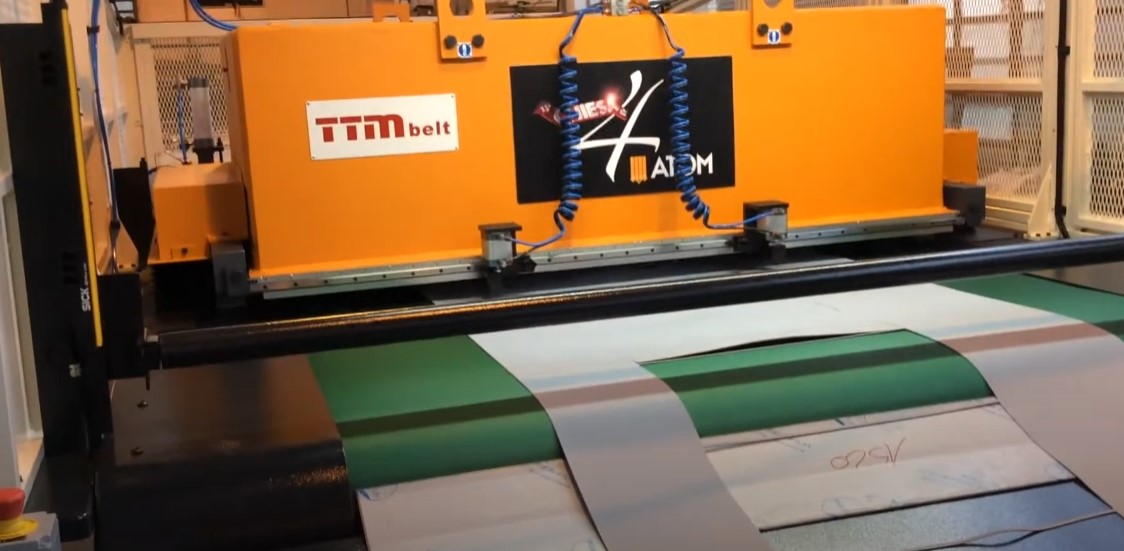

The standard Chiesa F1 EDI CNC Die Cutting System structure and has been strengthened and designed to sustain a new moveable trolley with a “C” structure on the lower extremity of which the female die holder is installed. The material indexing is provided by a “pinch & grab” system with two pincers; one that is moveable for material feeding and the second which is fixed to hold the material in place during the cutting operation. During the indexing, the material slides on two metal plates placed on the front & back of the female die holder which can move freely between these two plates. The die cut components fall onto a conveyor that transport them to the outside of the machine for efficient handling.

Match-metal die cutting is the process of cutting materials by passing the materials through the blades of a cutting die which is constructed of a top die and a bottom die and are matched (male/female) to provide an extremely precise cut. Match-metal die cutting is used in applications which require extreme precision and are designed to cut a wide range of thin substrates & specialty materials for medical, industrial, electronics, consumer care & other thin substrate die cutting applications.

Typical substrates and specialty materials that are die cut with matched metal dies include gasket materials, thin steel, technical textiles, nonwovens and composites, films (PP, PE, PET etc..), adhesive coated laminates & tapes, open & closed cell foams,

Benefits with matched metal (male/female) tooling:

- Extreme cutting accuracy – high tolerance capabilities

- Ideal for cutting complex geometries or small features

- Burr free cutting

- Elimination of the edge bending

- Clean cutting of very hard materials – engine head gaskets.

Chiesa are considered the market leader for industrial die cutting applications – particularly for the abrasive, automotive, gasket, electronic & medical sectors. The long experience gained in the automatic cutting industry through thousands of installations and the steady dialog with our customers helped in creating a reliable, safe, user friendly performing product.

These die cutting systems are extremely efficient. The robust structure and the quality of mechanical components allow cutting speeds beyond 100 punches per minute, with a precision of a few hundredth of a millimeter, which allows parts to be kept as close as possible, increasing the material savings & tooling life.

Points of Strength

- EDI Technology: The first electrically servo driven automatic CNC die cutting press (NO HYDRAULICS) – Eliminates all components associated with hydraulics; i.e. hydraulic oil, seals, pumps, valves, hoses, filters, hydraulic tank etc..

- Energy Savings – GREEN Technology: Reduction of direct power consumption by 50% – the higher power is only required while cutting; minimal power is absorbed while in “hold” or during the accessory operation like Y & Z axes movements.

- Rapid Die Set-Up: Compared to a traditional hydraulic system, no down-stroke movement in low pressure is required to the set the die height. Simply enter the tool height, 23.8mm as an example, and the die setting is complete.

- Accurate Die Setting: The die setting tolerance is in the range of one hundredth of a millimeter (0.01mm), thus allowing a perfect penetration of the die into the material & remarkably reducing the belt consumption. The setting is so accurate; you are able to perform kiss-cutting operations on laminated materials.

- Reduced Noise Emissions: The electrically servo driven cutting head is virtually noiseless; you can barely hear the machine operate.

- Reduced Maintenance: The ball screw driving the cutting head does not require any maintenance. The absence of the hydraulic system avoids the need of maintenance, like hydraulic oil & filter replacement, gasket & seal wear, high-pressure hoses, pumps, valves etc.

- Air Conditioned Electrical Cabinet: Keeps the electronics cool and eliminates any dust or debris from entering the cabinet.

Advantages

- Rigid Construction – Designed for Reliability & Low Maintenance: This die cutting press is a pure CNC machine, not a manual press retrofitted with automatic features. The construction of the press, designed on the latest CAD systems, is the most robust and rigid available. The ball screw driving the cutting head does not require any maintenance. The absence of the hydraulic system avoids the need of maintenance, like oil & filter replacement, seal & gasket wear, high-pressure hydraulic hoses etc..

- Material Savings: The quality of design and components allows extreme precision in positioning, minimizing the distance between cut pieces. The automatic nesting software calculates automatically optimal layouts to take advantage of the allowed precision.

- Time Savings and Increased Flexibility: The software can prepare the cutting program in a few seconds. Using a die plate it is possible to change the die very quickly from the side of the press or when equipped with the automatic tool changing device, a die can be changed in as little as 10 seconds – automatically. This fast configuration change makes even the cutting of small production batches, of a few hundred parts, cost effective.

- Labor Savings: The system allows high quality cutting even with inexperienced operators. A single CNC cutting machine can substitute 3-5 traditional trolley presses and their skilled operators. The die setting is quite simple and can be done by simply entering in the tool height unlike a hydraulic system which requires a low pressure set-up.

- Low Operating Costs: The special design, which takes advantage of patented Chiesa solutions, grants high cutting power and speed with limited power consumption. The higher power is required when cutting only, very low power is absorbed while in “hold” or during the accessory operation like axes movement. On average, our customers typically see a 50% reduction in energy consumption when compared to traditional hydraulically operated die cutting presses. The quality of components reduces the maintenance costs and minimizes the time associated.

- Easy Operation: No special skills are required to operate the press. Your current press operators can use it. Machine programming and nesting may be carried out either locally or remotely from your production planning office. Cutting programs can be transferred through network or thumb drives. The work schedule automatically controls the press and informs the operators when material and tool changes are required. If your material width varies, or rush jobs require immediate priority, the operator can instantly re nest the schedule to accommodate these changes. Standard cutting tools are fitted onto a simple steel carrier plate and easily replaced on the cutting head in less than ten seconds via the automatic tool changing device.