Chiesa

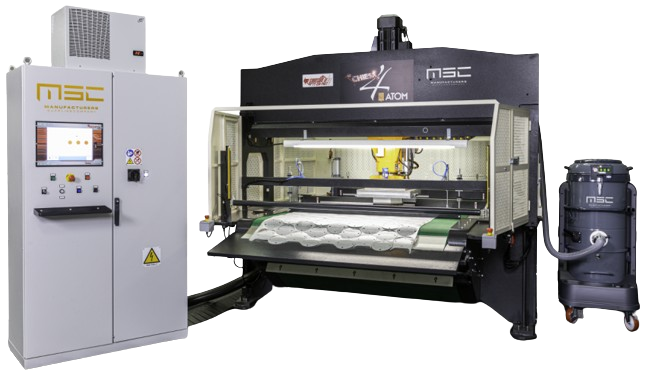

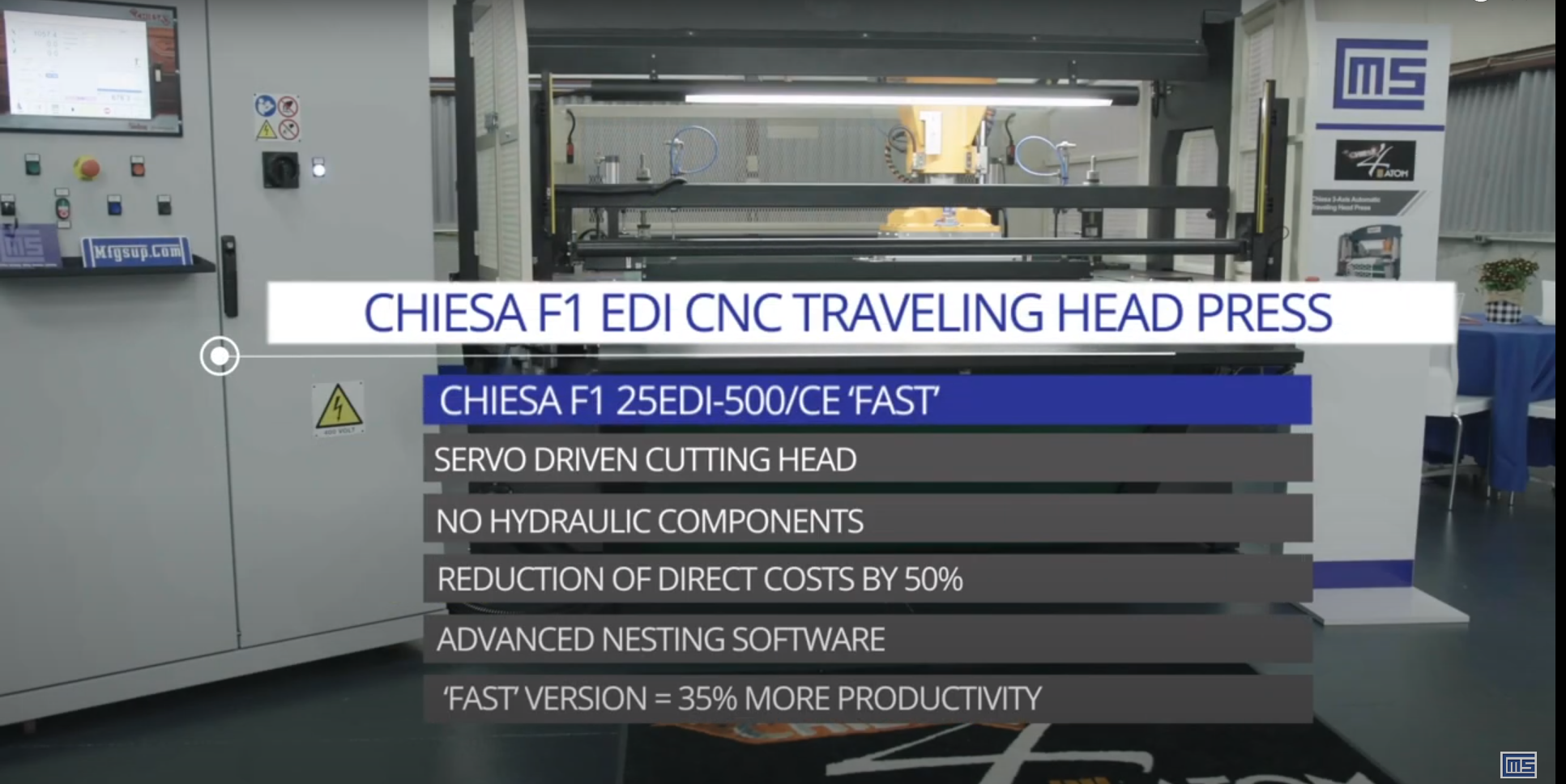

F1 Automatic TRAVELING HEAD PRESS

This ‘GREEN’ technology reduces power consumption up to 50%, eliminates all the maintenance associated with hydraulic components, and improves overall accuracy, repeatability & production throughout. In addition, to improve overall productivity & material yields, the press is equipped with either a 4, 7 or 14 position automatic tool changing device which is attached to the side of machine.

Chiesa are considered the market leader for industrial die cutting applications – particularly for the abrasive, gasket & automotive sectors. The long experience gained in the automatic cutting industry through thousands of installations and the steady dialog with our customers helped in creating a reliable, safe, user friendly performing product.

These die cutting systems are extremely efficient. The robust structure and the quality of mechanical components allow cutting speeds beyond 100 punches per minute, with a precision of a few hundredth of a millimeter, which allows parts to be kept as close as possible, increasing the material savings & cutting belt life.

The cutting power, up to 110 tons, is kept steady even for extremely long production runs allowing these machines to cut hard materials of high thickness, in single or multiple layers, and use multiple dies or dies with long blade development. Wide variety of modular feeding systems available for both roll & sheets in single and multiple layers:

Cutting Belt & Feeding Clamps

Suitable to cut any type of synthetic material both in rolls and sheets, loaded both from the front or back of die cutting press; the material is moved and fixed by three independent clamps. One clamp is mobile and supports the belt in the movement of the material to grant the maximum positioning of the material(s) even for soft, elastic products, cut in single or multiple ply.

Mobile Cutting Pad & Clamps

Suitable to cut sheeted goods only, both in single & multiple layers. The sheets are loaded onto a polypropylene cutting pad with automatic movement and equipped with special clamps. The clamps allow the cutting of multiple layers without stapling.

Automatic Sheet Feeding

The material is loaded onto a hydraulic platform, both in single or stapled multiple layers. A special vacuum suction cup device grips the material and positions it onto the back of the machine. The feeding system will automatically stop the machine when there is no longer material available. The sheet feed system is available on all models equipped with the cutting belt & clamps. The system can also be equipped with an automatic part unloading device.

The advanced nesting software allows to calculate, with considerable precision, for each material consumption and time required (thus labor cost) in order to make accurate simulations of the cutting cost, enabling better production planning and more precise offers to customers.

Manufacturers Supplies Company

has installed over 300 CNC die cutting systems throughout North America. We provide complete support for both hardware and software along with on-line diagnostics and software assistance. MSC has appointed service technicians exclusively to maintain our CNC equipment and this is why we stand above the rest because we “service and support what we sell.”

Material Handling Solutions

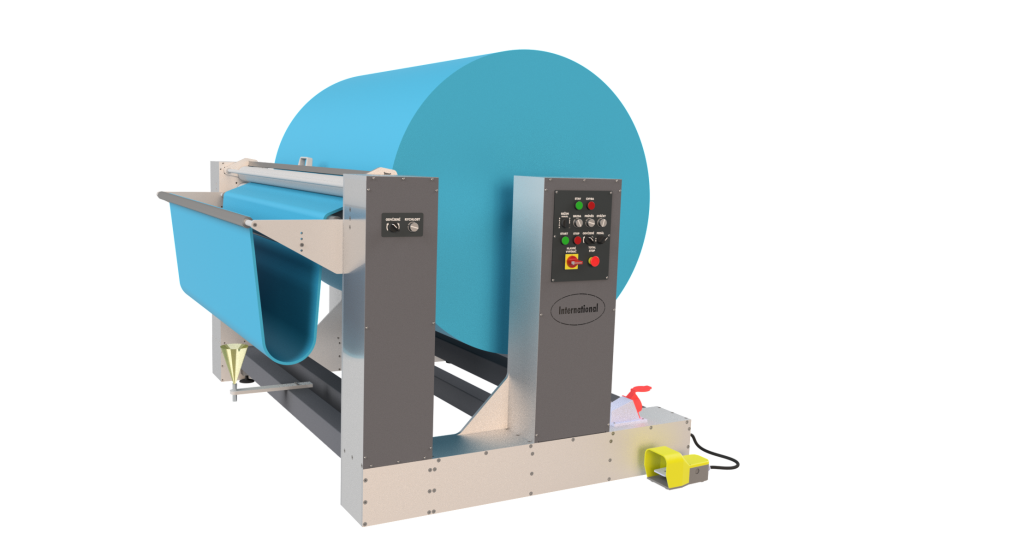

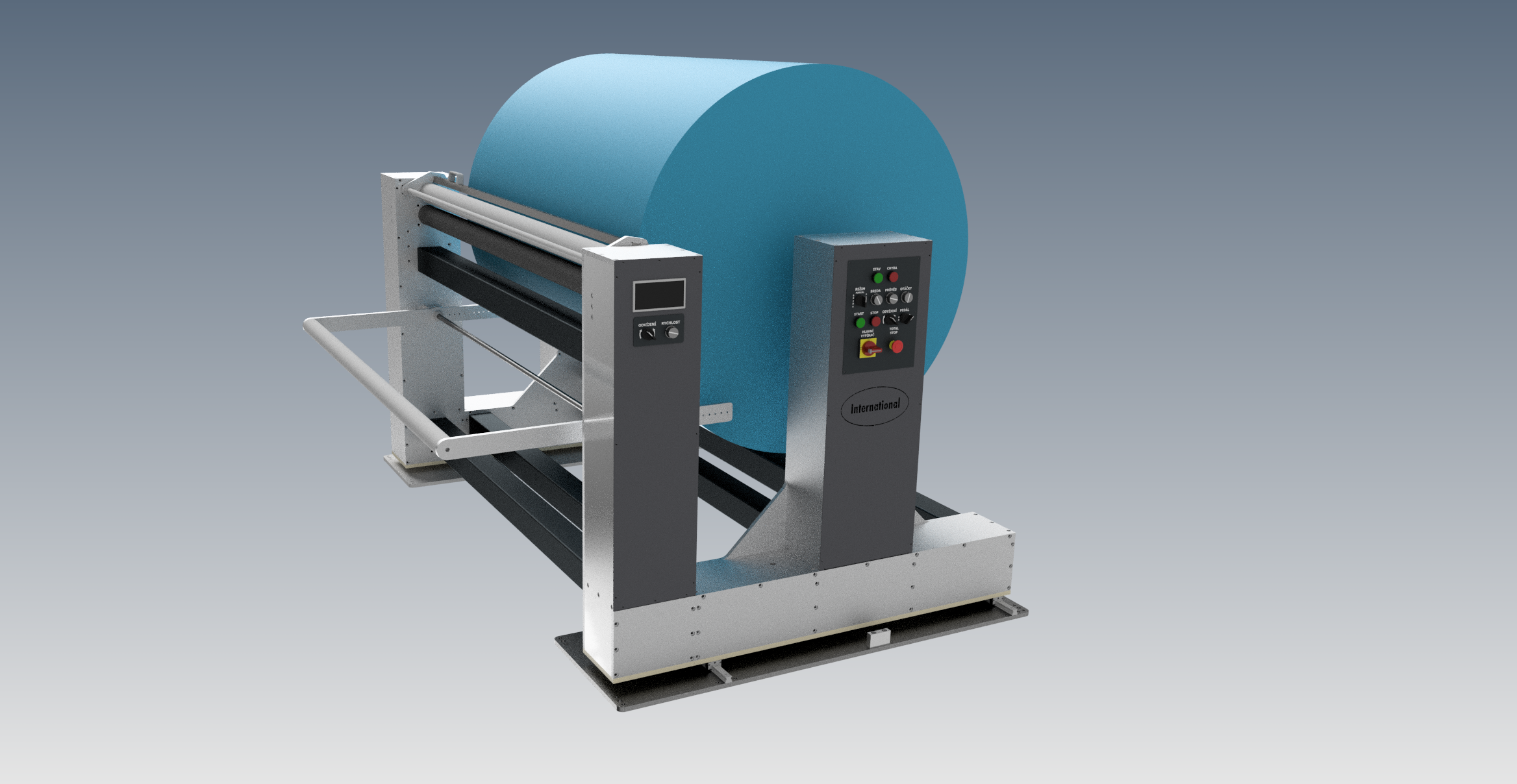

International Unwinders-Rewinders

PDF - 720 KB

The machine is equipped with:

Dancer: A sensor for monitoring material sag, controlling the drive shaft based on its data. Winding with sag allows for reduced stretching during material uptake

The machine is equipped with:

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Sensor: Monitors material sag, adjusting winding speed accordingly

The machine is equipped with:

Dancer: A sensor for monitoring material sag, facilitating reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Side Control: A device for aligning winding; it adjusts the position lightly if the material is unwound off-center.

The machine is equipped with:

Dancer: A sensor for monitoring material sag, optimizing drive shaft control for reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder

The machine is equipped with:

Dancer: For sag monitoring and optimized drive puller, ensuring reduced material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: Ensures precise winding alignment, adjusting position if material is unwound off-center.

The machine is equipped with:

Dancer: For sag monitoring and optimized drive shaft control, minimizing material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: For accurate winding alignment, making slight adjustments if material is unwound off-center

The machine is equipped with:

Loader: A device for enhanced material handling, automatically raised by the machine for improved efficiency.

Puller: Assists the drive during winding

The machine is equipped with:

Holder: A device for shaft retention, with a maximum capacity of 4 units.