Chiesa

RH Series

The Chiesa RH Series Receding Head Full Beam Die Cutting Presses features all the advantages achieved from a traditional full head beam die cutting machine with the addition of the increased visibility of the machine’s working surface.

The shoulder supports are linked to the movement of the hydraulic cylinders as well as being guided by guide units for the vertical movement. The receding beam is constrained to the shoulder supports which represent the heart of the guide system. The guide unit (sliding type) is solidly linked to the machine base structure & the anti-friction material is non-compressible to operating pressure, with an extremely low friction level even in dry mode.

Material Handling Solutions

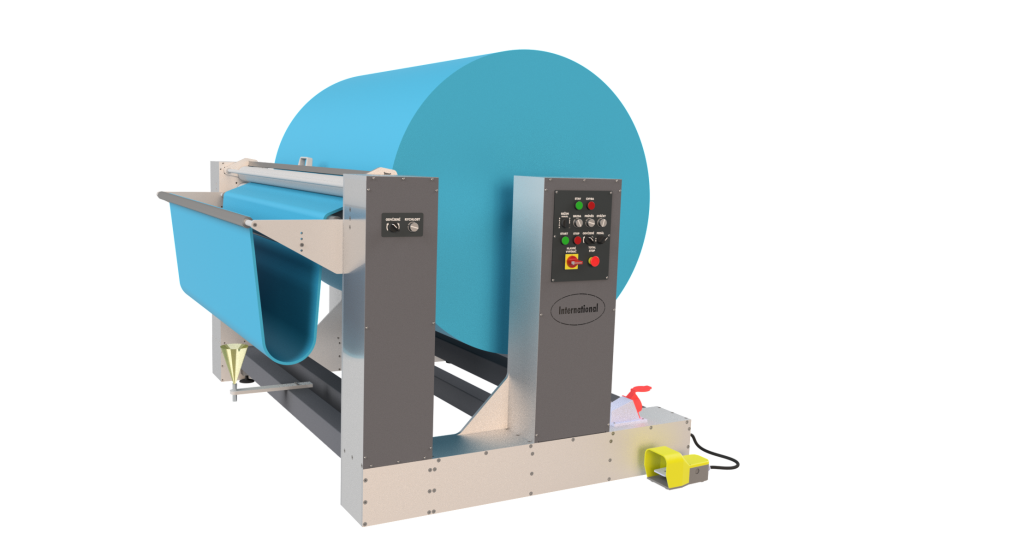

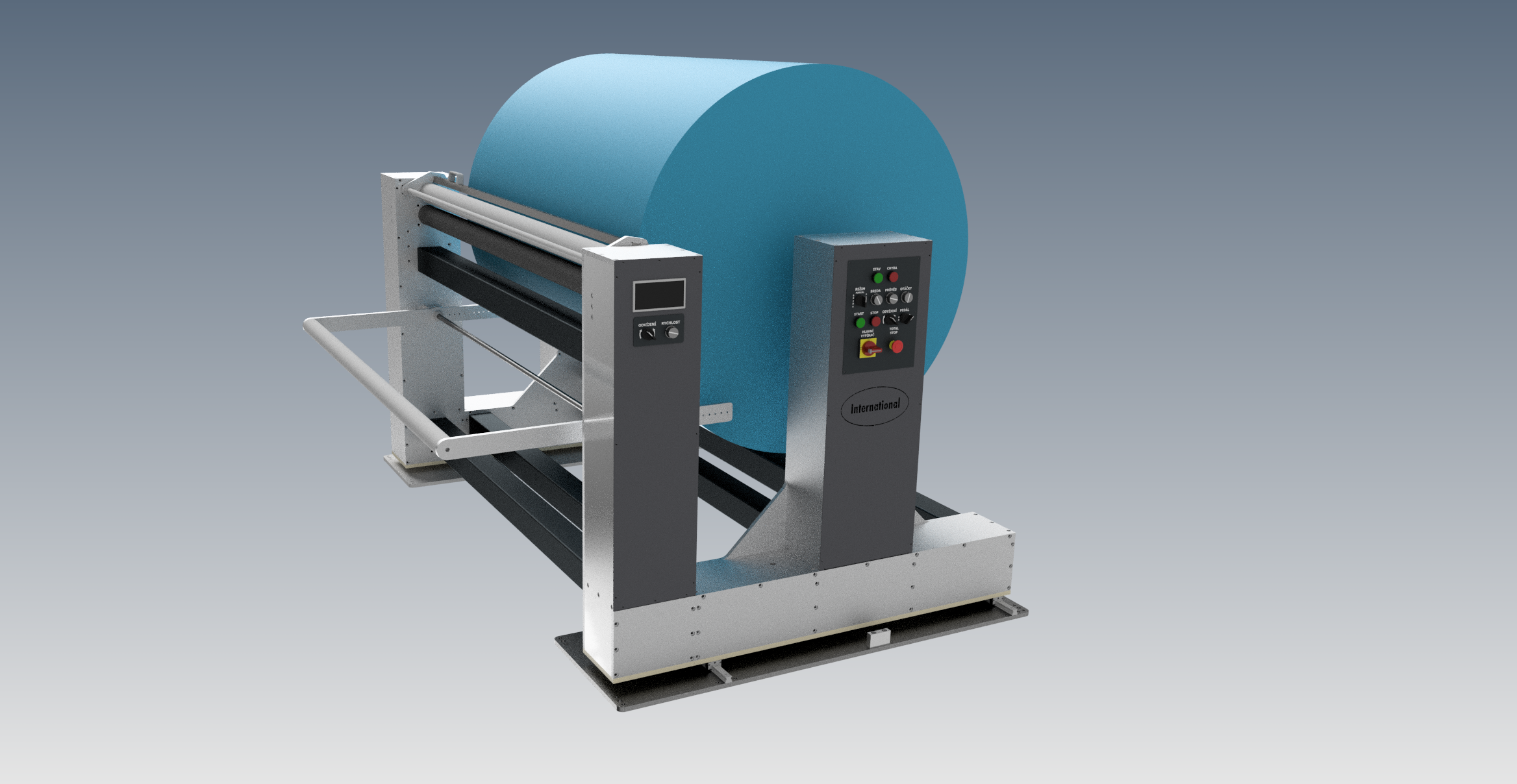

International Unwinders-Rewinders

PDF - 720 KB

The machine is equipped with:

Dancer: A sensor for monitoring material sag, controlling the drive shaft based on its data. Winding with sag allows for reduced stretching during material uptake

The machine is equipped with:

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Sensor: Monitors material sag, adjusting winding speed accordingly

The machine is equipped with:

Dancer: A sensor for monitoring material sag, facilitating reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Side Control: A device for aligning winding; it adjusts the position lightly if the material is unwound off-center.

The machine is equipped with:

Dancer: A sensor for monitoring material sag, optimizing drive shaft control for reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder

The machine is equipped with:

Dancer: For sag monitoring and optimized drive puller, ensuring reduced material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: Ensures precise winding alignment, adjusting position if material is unwound off-center.

The machine is equipped with:

Dancer: For sag monitoring and optimized drive shaft control, minimizing material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: For accurate winding alignment, making slight adjustments if material is unwound off-center

The machine is equipped with:

Loader: A device for enhanced material handling, automatically raised by the machine for improved efficiency.

Puller: Assists the drive during winding

The machine is equipped with:

Holder: A device for shaft retention, with a maximum capacity of 4 units.

Downloads

Download CHIESA TTM Receding Head Press

PDF - 1.00 MB

Download CHIESA TTM Open With Mechanical Stop

PDF - 2.00 MB

Start a Conversation

Get in Touch

Don’t hesitate to contact us by calling the numbers below or filling out the form link.