ATOM Manual

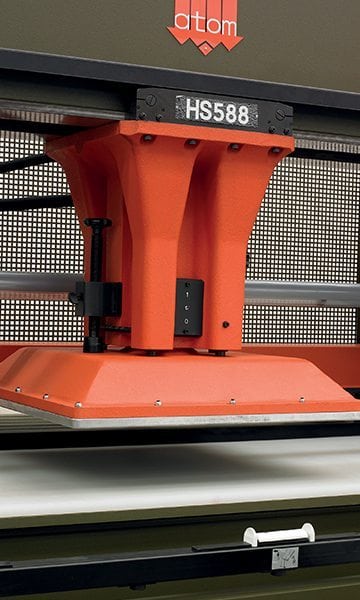

Traveling Heads

ATOM traveling head die cutting presses offer a wide & easily accessible working area suitable for cutting a wide variety of synthetic materials in either roll or sheet form.

ATOM Traveling Head Press Training Video

The cutting platen is motorized and chain & sprocket driven with either manual or automatic head movement left-right via timer. The machine operator simply places the cutting tool on the material, actuates the push-button on the side of the head to position the beam over the die, cycles the two-hand push button controls (3/10 second delay for optimal safety) & the platen descends under hydraulic pressure, cuts the shape, and returns to the pre-set location so the operator can pick the cut piece(s) with full visibility of the illuminated work surface.

The main features of a traveling head press are defined in two ways; structural & control system. Structural refers to cutting power, working area dimensions, material size and cutting platen dimensions. Control system refers to automatic power & stroke end adjustment, automatic detection of die position on cutting surface & automatic trolley displacement.

All models can be equipped with a variety of options including;

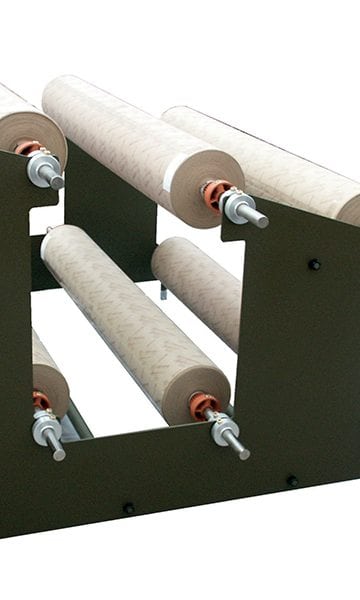

- AL Series Semi-automatic nip roll feeding system

- Roll material carts (Designed Accordingly)

- Simple or programmable cut counting device

- Overload / Under voltage protection device

Traveling Heads 588 CE Version

All 588-Series models are available both in CE version and in non-CE version and in two different adjustable cutting strokes: up to 100 mm or 150 mm, according to the material thickness or the number of layers to be cut.

Points of Strength

- High speed of trolley positioning & cutting which ensures increased productivity.

- Pushbutton controls (time interlock synchronization during cutting phase) to ensure optimal safety for the operator

- Automatic adjustment of cutting power

- Dynamic brake system, which improves performances & reduces the motor consumption

- Patented hydraulic system that limits power consumption by using motors with less HP than our competitors

- Heavy duty framework, extremely rigid & resistant, designed with top quality components which ensure low maintenance costs

- Consistent cutting power for continuous use

- Overload / Under voltage protection device

Downloads

Download ATOM 588 Series Brochure

PDF 191 KB

+PLUS|Traveling Head Presses

Time Interlock Synchronization

Pushbutton controls with time interlock synchronization during cutting phase ensure maximum safety to the operators and allow great precision both in trolley motion and in cut.

Dynamic Breaking

System

The exclusive and powerful dynamic braking system stops the trolley in a very short time; virtually no wear and tear of the motor gear box unit and no need for primary maintenance.

Programmable

Cut-Counter

Every machine is available with an optional cut-counter, to control the exact number of pieces cut or to plan the automatic stop of the cutting sessions as the planned quantity is reached.

Feeding

Systems

To optimize productivity, every 588 series model can be equipped with feeding systems for materials in roll, both manually and motorized.

Downloads

Download ATOM 588 Series Brochure

PDF - 191 KB

Download ATOM Traveling Head Overall Dimensions

PDF - 86 KB