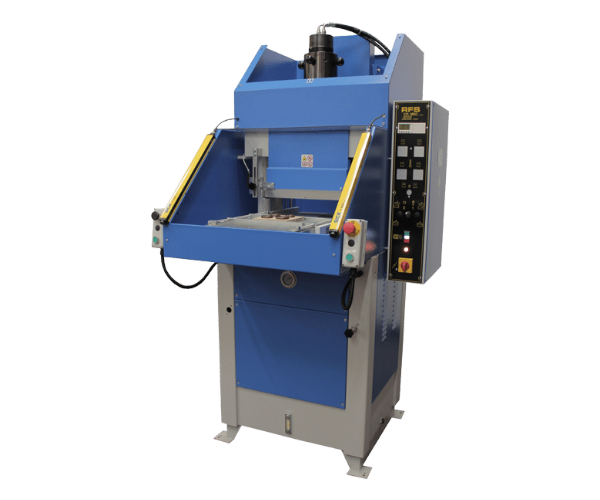

RFS Co.MEC

Plating & Hot Stamping Presses

The RFS Co. Mec hydraulic up-stroke platen presses for printing & stamping, plating, & embossing leather goods, shoe components, textiles and synthetic materials.

The adjustment of the impression or die cut is controlled via the PLC + Touchscreen with the following confirmed:

- Automatic detection of the die height

- Electronic confirmation of impression depth

- Proportional valve to check pressure on the PLC

The upper and lower heated platens are controlled by 3 independent temperature regulators, or three independent zones, for precise temperature control. Pressure, controlled heat and dwell time are the key elements that make the RFS line of hydraulic plating & hot stamping presses the leaders in the industry.

Work areas range from 200mm x 300mm up to 1400mm x 900mm with working pressures from 10 to 220 tons. Working table can include semi-automatic or fully automatic shuttle trays, or a rotary table with two positions for increased production throughput.

Preforming & Screen Printing

The RFS Co. Mec PV Series presses are fast and completely reliable machines for the preforming of soles and insoles. The ascent of the piston is particularly quick due to its acceleration system, so as to ensure high productivity. The machines are equipped with a photocell system to ensure the highest level of safety for the operator. The pressure is regulated by means of independent valves. The pressing time is controlled by a PLC. The machines are also equipped with a heating unit for the upper part of the mold and, on request, can supplied with lower heating for the use of chrome plated molds.

RFS also manufactures hydraulic presses for screen printing soles and insoles in leather, split leather, and bonded leather, with fully automatic transport and timing in 2 positions, for maximum production throughput with up to 2,500 pairs in an eight hour shift.

Presses for Leather Belts

The RFS 92C series belt presses can be used for plating, hot stamping, embossing and punching leather or synthetic belts. The machines are equipped with an automatic carriage & safety photocell barrier for maximum operator safety. The 92C series belt press are equipped with 3 interchangeable belt housings, a centering system to facilitate the belt positioning, with working area from 100mm x 1300mm up to 190mm x 1500mm. The B15 series are used for plating, hot stamping and belt slicing and are designed with an automatic foil transport & mechanical stop to set the printing depth.

Downloads

Download Platen Presses Specifications

PDF - 111 KB

Get in Touch

Don’t hesitate to contact us by calling the numbers below or filling out the form link.