Guidolin Girotto

Flat Bed Series

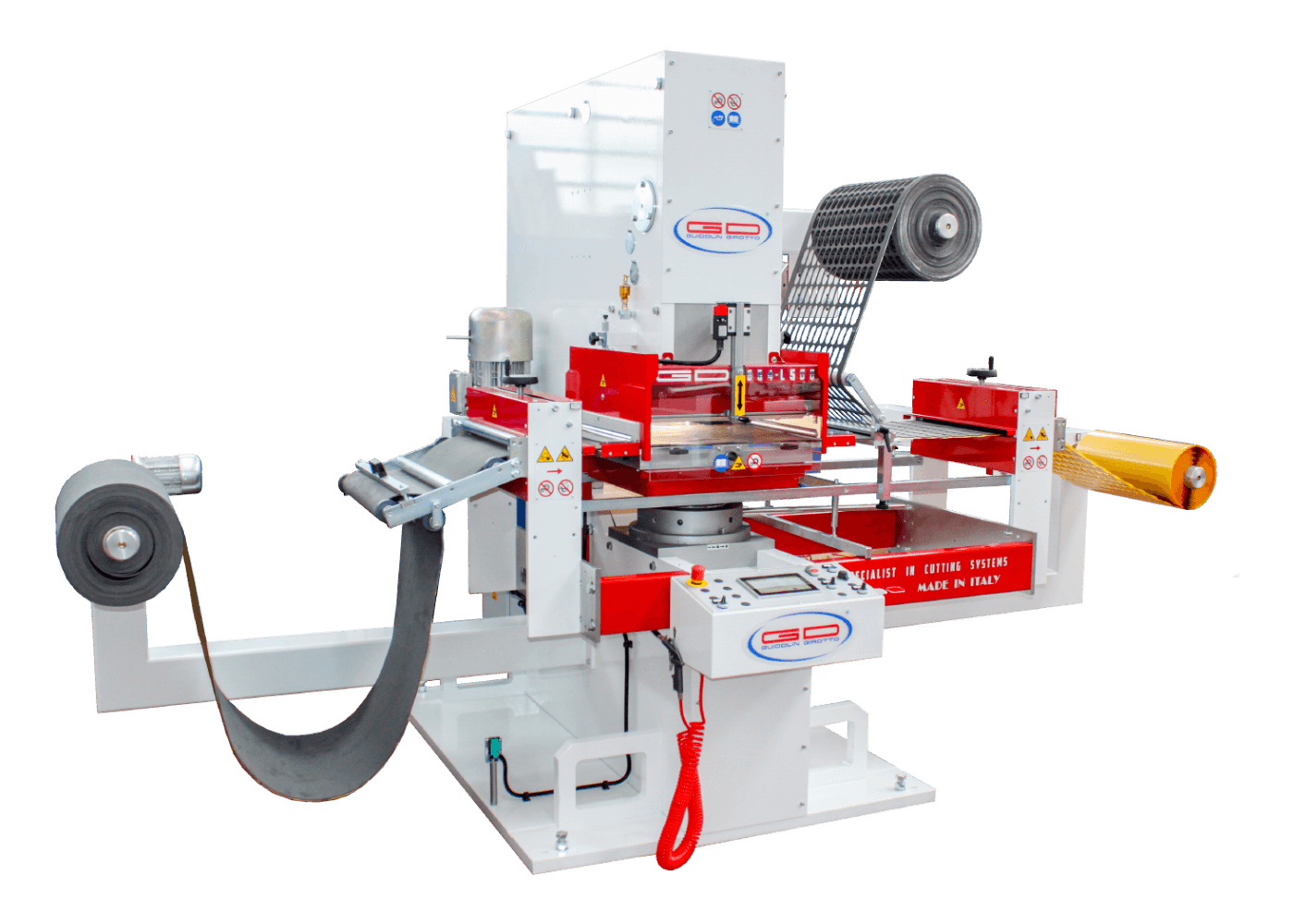

Guidolin Girotto Srl, the leading manufacturer of standard and custom engineered automatic electro-mechanical flat-bed die cutting & kiss cutting presses offers a complete range of narrow web converting machinery with cutting powers ranging from 5-10-20-35 tons and platen sizes ranging from 200-320-400-500-600mm (Special sizes upon request) with production speeds from 30 to 150 cycles per minute.

The Guidolin range of flat-bed die cutting & kiss cutting machinery are entirely mechanical & electronic, therefore they require minimal maintenance & considerably reduce electrical consumption. The mechanical operation and single cylinder micrometric adjustment allows for higher cutting power & precision, less set-up and noise-less operation. The working parameters are managed by an industrial Touchscreen & PLC which can store up to 500 different jobs to guarantee quick & easy changeover. The special software, with immediate interface, grants a high feeding accuracy to reduce material waste and dramatically increase production throughput.

Technical Material Converting

Due to the modular design, single cylinder adjustment, rapid die change accessibility and ease of set-up, these machines are ideal for companies that need to convert a wide range of materials and applications in a given shift – reduce time and labor, save on die costs and improve on overall material yields.

Recognized worldwide as the machine of choice by the most prominent converters for a wide variety of materials & industrial sectors:

- Converters of adhesives and double sided adhesive tapes (3M, Lohmann, Avery, TESA)

- Abrasives – Kiss cut discs, polishing pads

- Converters in the automotive sector (car emblems, internal gaskets)

- Converters of neutral and/or printed labels

- Converters of paper & plastic materials

- Foam materials with open or closed cells / kiss-slitting (foam strip gaskets)

- Companies in the medical field

- Manufacturers of electronic devices

These die cutting systems process material in both sheet and roll form and operate with standard wood or plastic based steel rule dies, flexible etched dies, male/female dies or matched tooling to die cut or kiss cut the widest range of materials.

Quality construction, high precision, high cutting power, noise-less operation and quality/price ratio are distinctive marks that represent the Guidolin Girotto brand name worldwide.

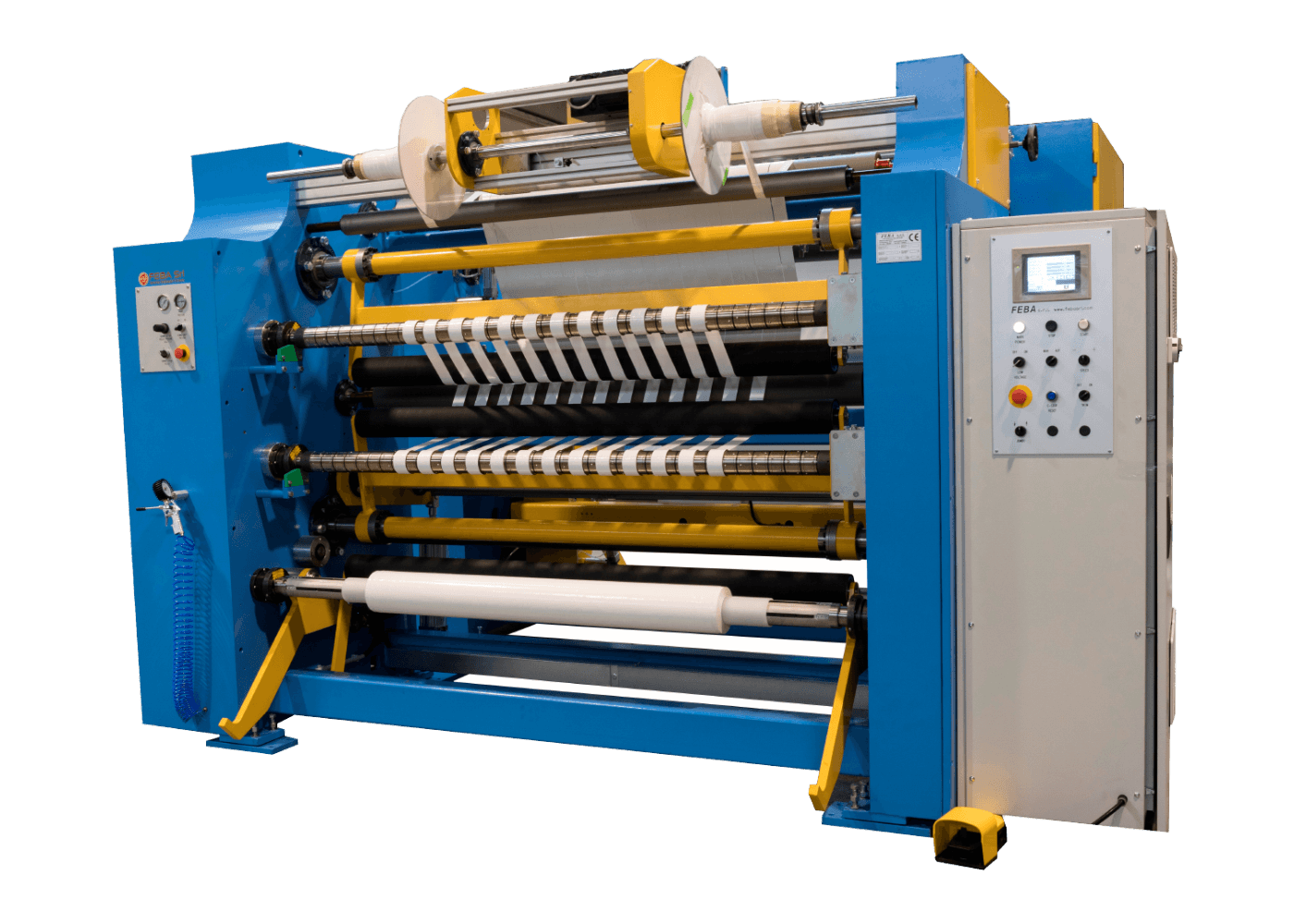

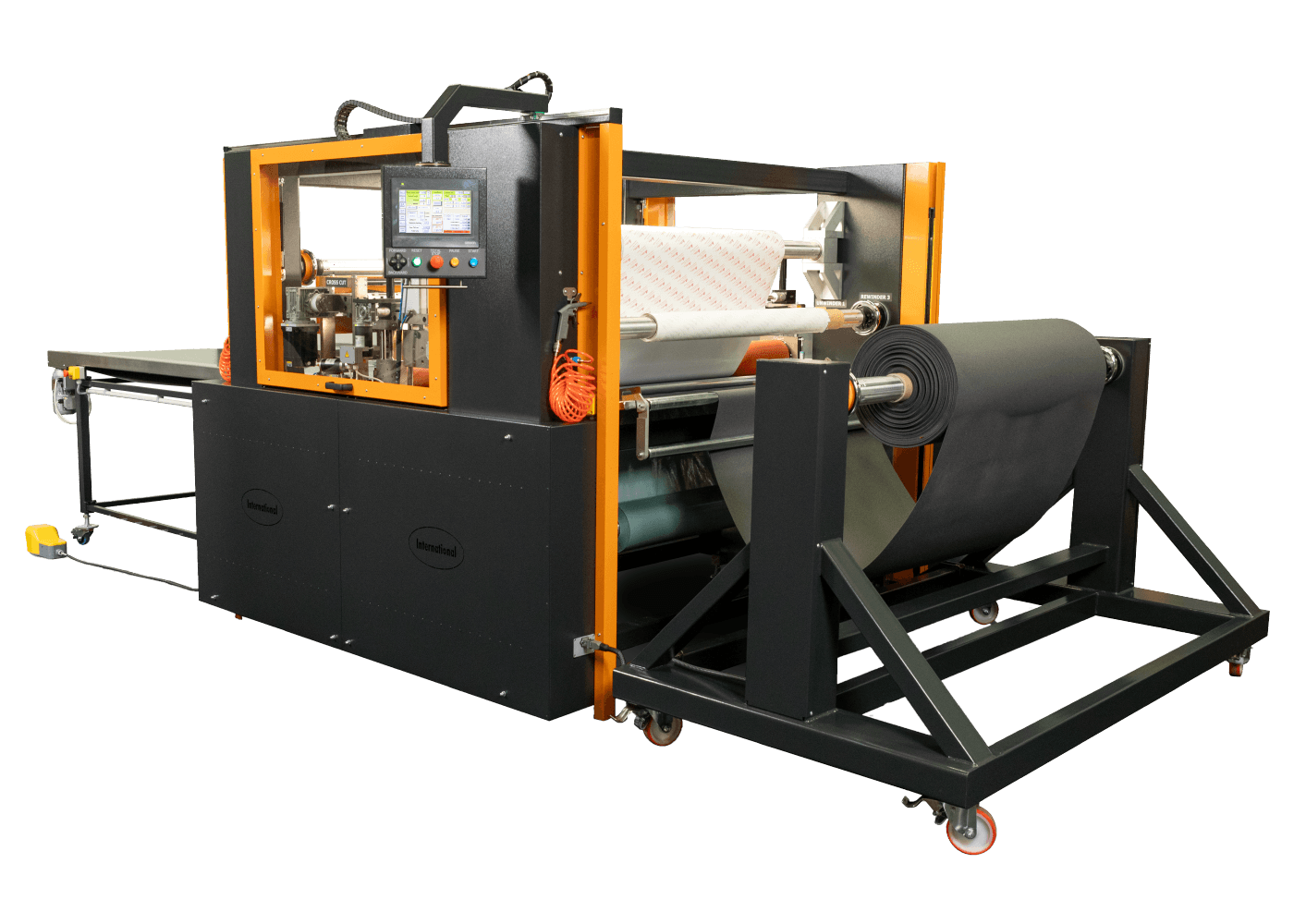

Versatility & Modular Design

The modular design allows for a wide variety of options to be added to automate and customize the system to suit your specific converting requirements. These options can include lamination, liner change assembly (change or add a liner), in-line rotary kiss-slitting, registration for pre-printed materials and in-line printing capabilities, scrap/matrix removal, part expulsion or stacking, transversal guillotine cutting, longitudinal razor blade slitting, motorized rotary slitting, & rewinding. Guidolin Girotto pays close attention to the market trend, it’s changes, and to the customer requirements. Our team of engineers reviews your application and requirements, listen to your needs, and respond to offer a more innovative die cutting & converting solution to improve your current manufacturing process. Each machine is designed after a careful evaluation of the customer needs, the challenges of the material to be converted, therefore every machine produced is “made to order” for each client.

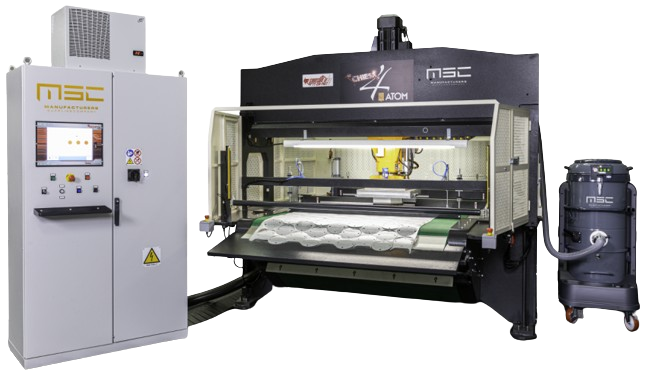

Flat Bed Die Cutting Presses

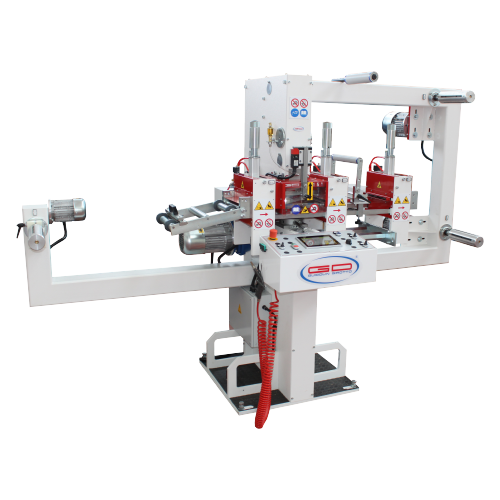

GD 151

The Guidolin Girotto high speed mechanical die cutting / kiss cutting machine, model GD 151D, is the ideal narrow web cutting press for converters of adhesive and double sided adhesive tapes, laminated foams (open & closed cell), converters in the automotive field (internal gaskets & car emblems), manufacturers of electronic devices etc.. The 151D automatic kiss cutting system develops 5 mechanical tons of cutting force, has a cutting platen of 200mm x 200mm, a fixed stroke of 40mm, with speeds ranging from 30-150 strokes per minute & special systems designed with speeds up to 300 strokes per minute.

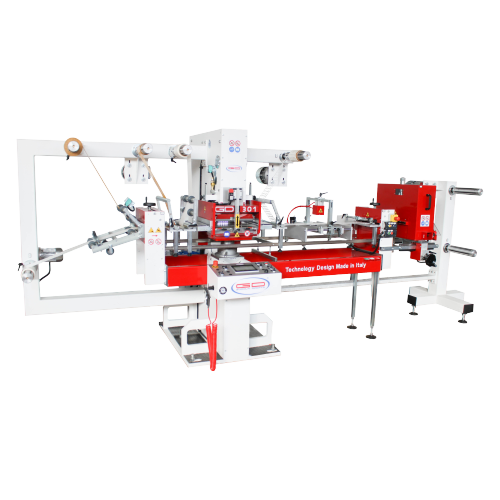

GD 301

The Guidolin Girotto narrow web flat-bed die-kiss cutting press, model GD 301D, is the ideal automated converting system for converters of pressure sensitive adhesive and double sided adhesives, foams & laminated foams (open & closed cell), converters in the transportation industry (internal gaskets & car emblems), manufacturers of electronic & medical devices, plastics etc.. The 301D high speed kiss cutting machine develops 10 mechanical tons of cutting force, has a cutting platen of 320mm x 320mm, a fixed stroke of 40mm, with speeds ranging from 30-150 strokes per minute.

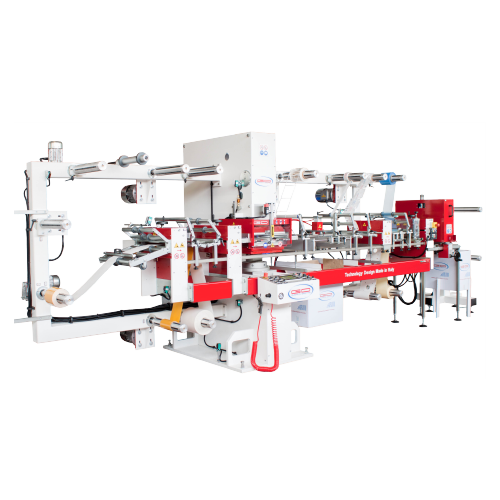

GD 401

The Guidolin Girotto automated flat-bed die cutting press, model GD 401D, is the ideal automated converting system for converters of pressure sensitive adhesive and double sided adhesives, foams & laminated foams (open & closed cell), converters in the transportation industry (internal gaskets & car emblems), manufacturers of electronic & medical devices, plastics etc.. The 401D high speed kiss cutting machine develops 20 mechanical tons of cutting force, has a cutting platen of 400mm x 400mm, a fixed stroke of 40mm, with speeds ranging from 30-150 strokes per minute.

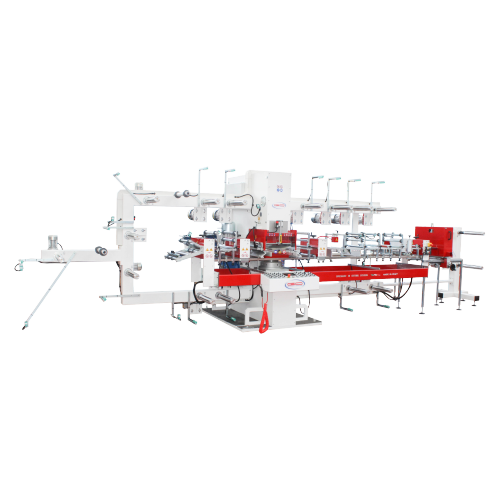

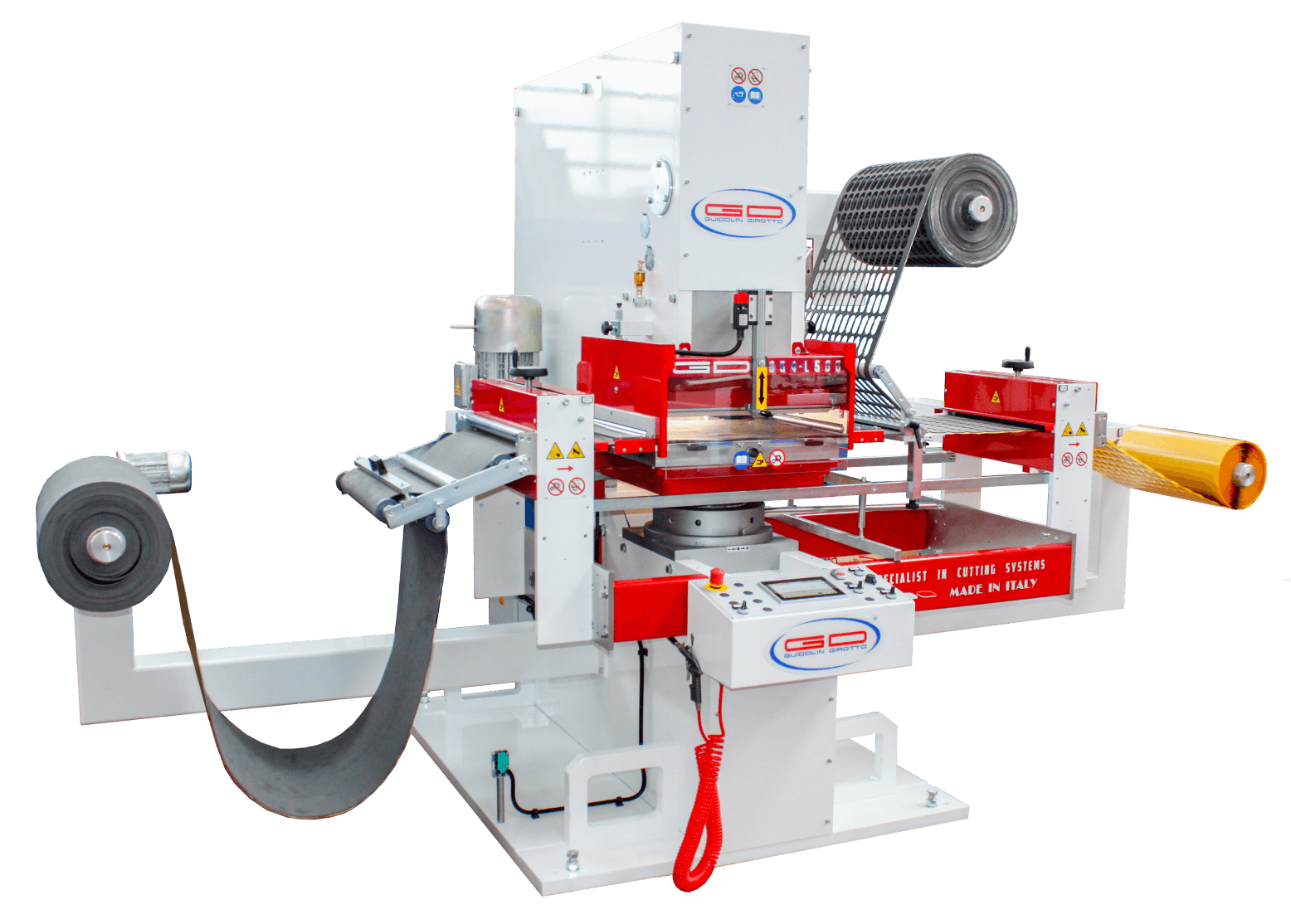

GD 654

The Guidolin Girotto high speed narrow web flat-bed die cutting systems, model GD 654D, are the ideal automated kiss cutting presses for simple & complex applications, & can be equipped with numerous optional systems to ensure excellent results in technical material converting. Recognized worldwide as the machine of choice for manufacturers & converters of self-adhesive tapes, single & double sided tapes, die cut tapes, glue dots, foams & laminated foams (open & closed cell), rubber & silicone rubber, converters in the transportation industry (anti-squeak & vibration control, acrylic foams, internal gaskets, car emblems, high bond adhesives), manufacturers of electronic & medical devices, textiles & non-textiles, plastics & similar materials. Our customers convert die cut and kiss cut tapes from the world’s leading manufacturers and are preferred converters of 3M, Avery Dennison, Lohmann Group, TESA, Nitto Denko, Tyco Adhesives, & Stokvis Tapes.

GD EL Series

The Guidolin Girotto models 151 & 301 EL automatic electro-mechanical flat-bed die cutting machines are the latest versions of the successful GD 151 D & 301 D lines. The new EL version keeps its solid frame structure, mechanical fly-wheel operation with micro-metric single cylinder adjustment for precise cutting tolerance & noise-less operation, yet represents some improvements related to the hardware and software, including the new TFT 4” color touchscreen. The rewinds are electro-mechanical with gear motors and mechanical friction with manual regulation which allows for accurate tension control.