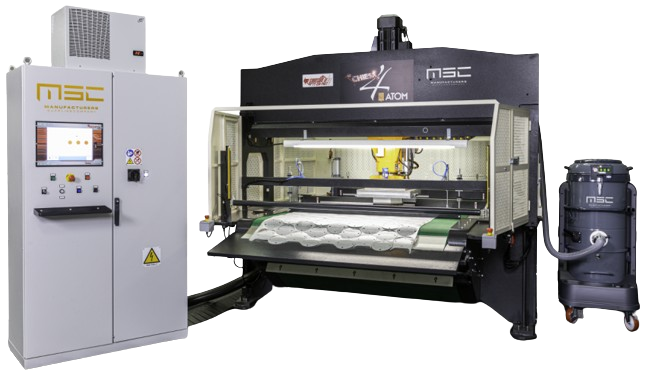

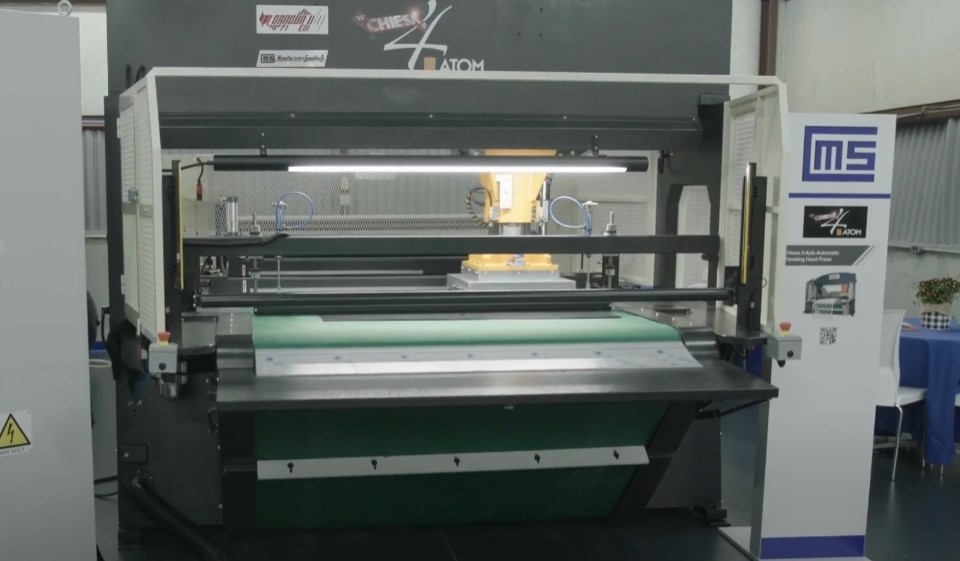

ATOM, Chiesa and RFS CO.MEC

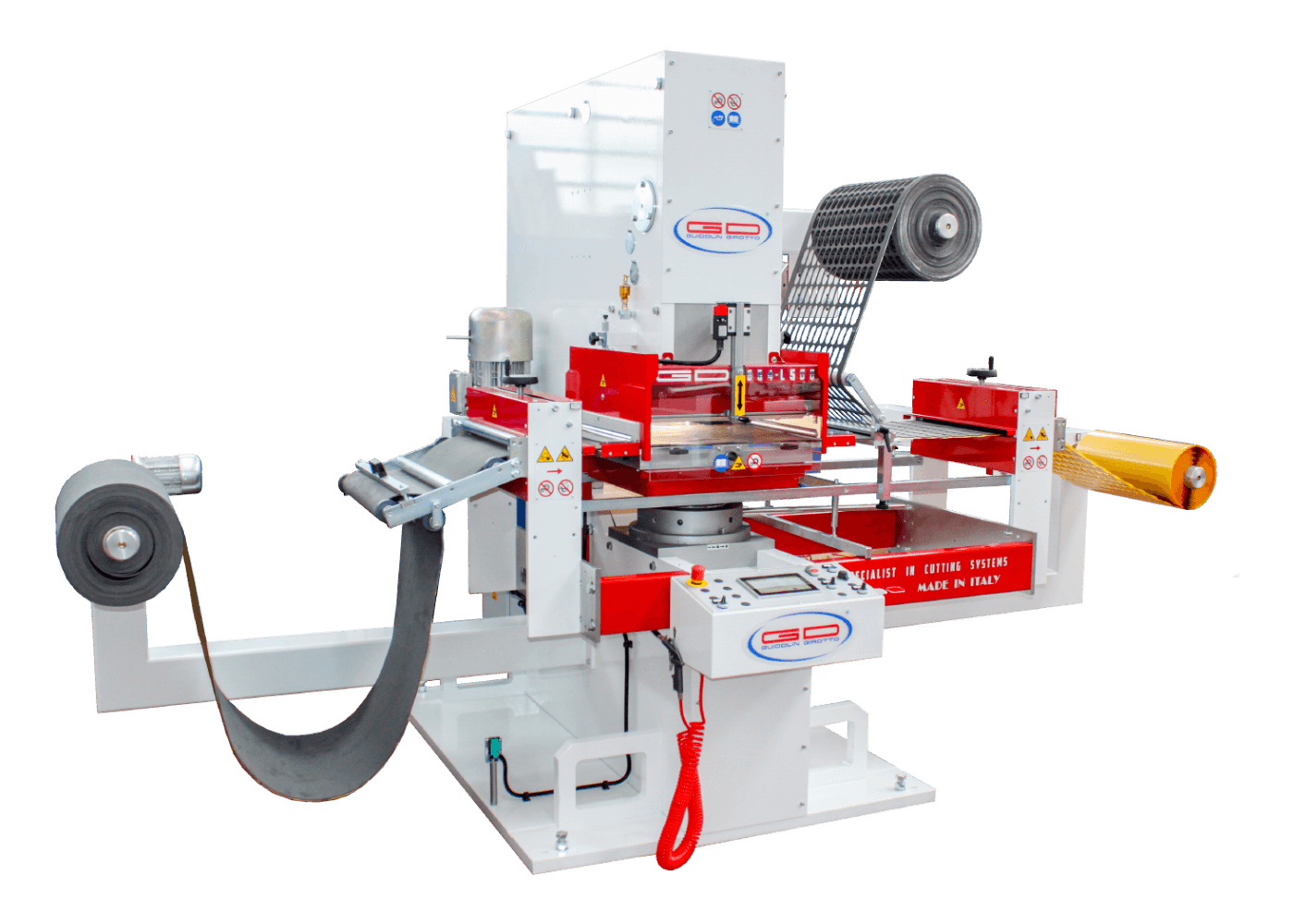

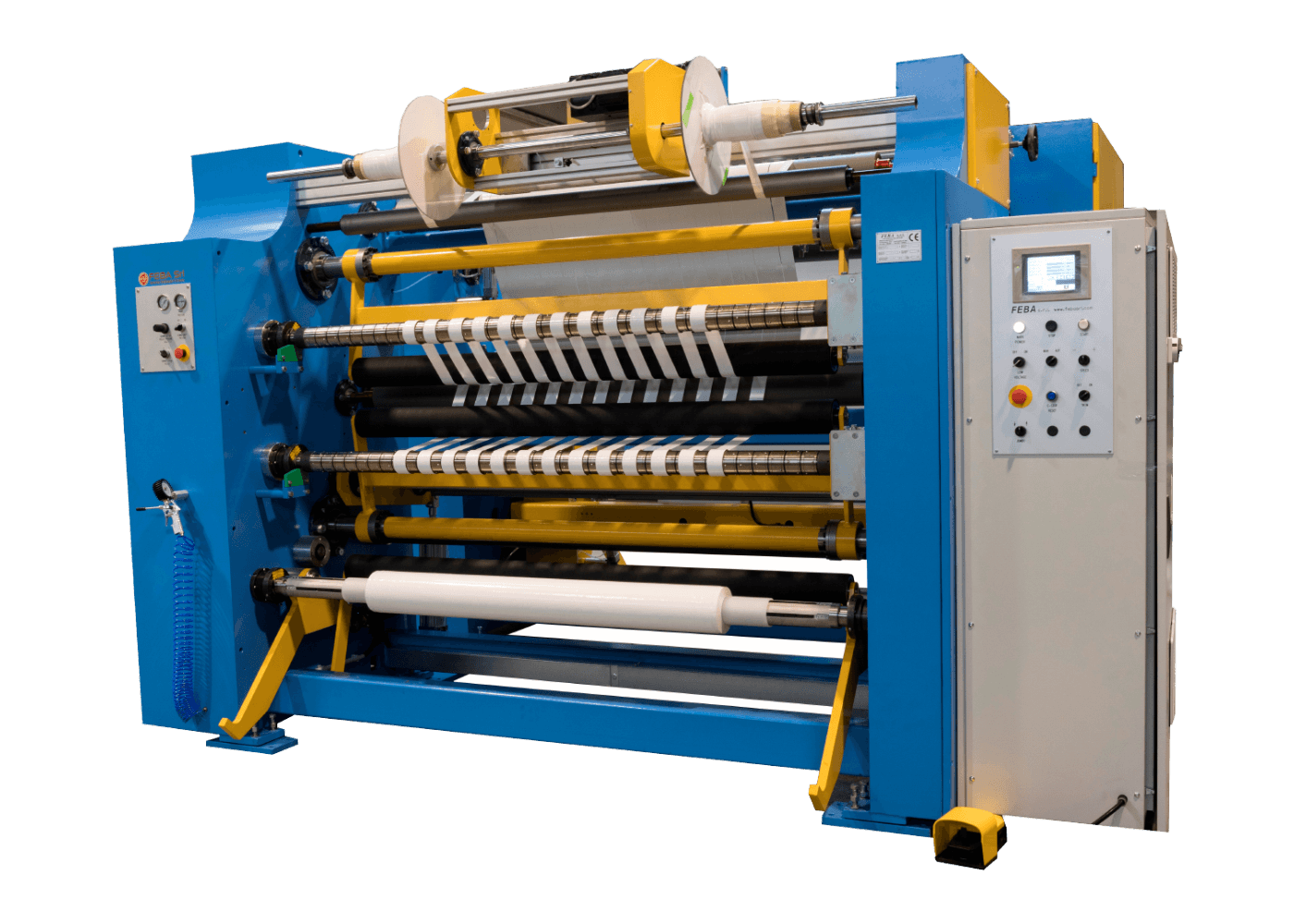

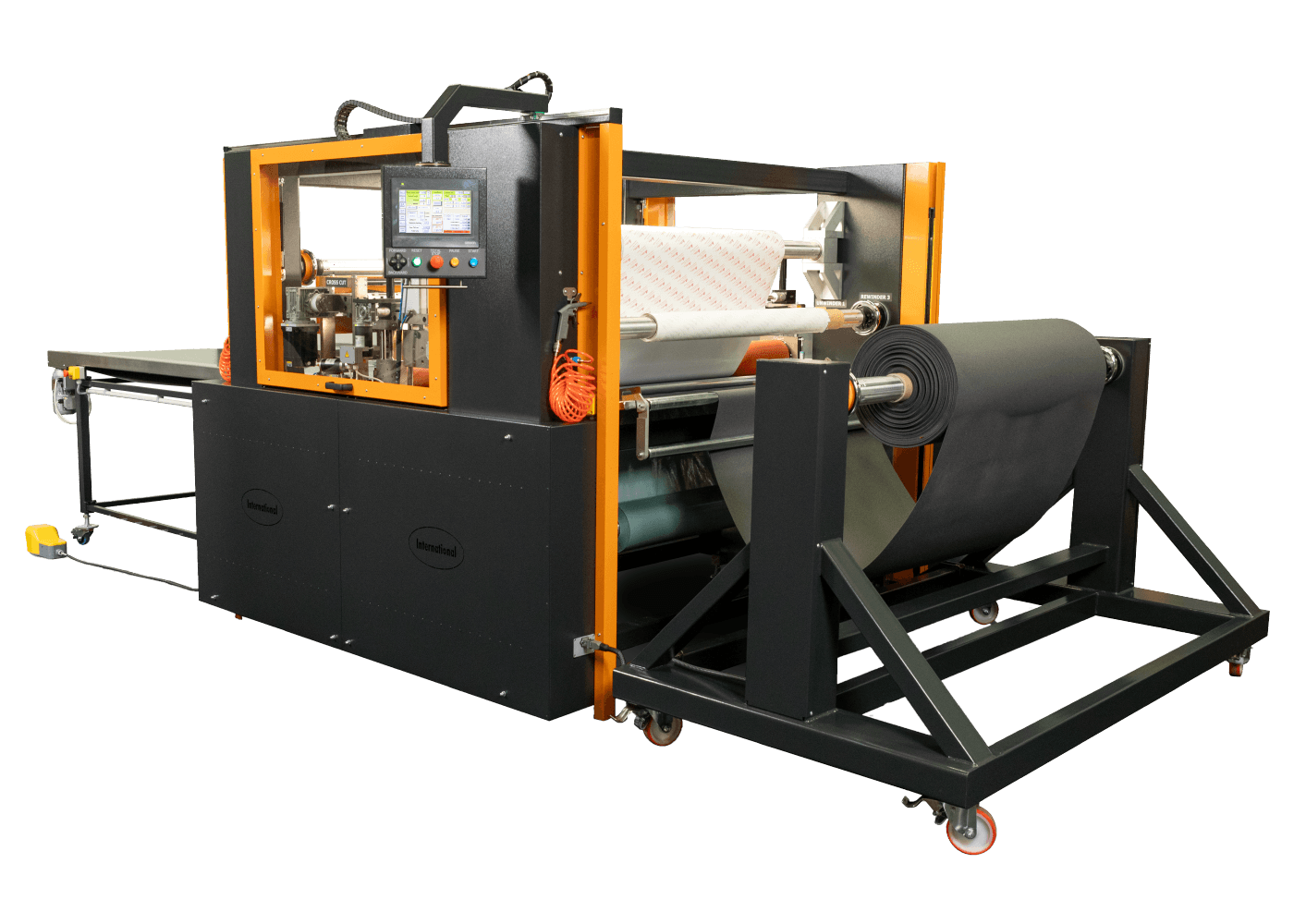

Die Cutting Presses

GROUP STRENGTH – Specialists in Innovative Technologies – Cutting Away with the Past.

ATOM SpA & Chiesa Artorige (Vigevano, IT), with over 60 years of experience in the die cutting equipment sector aiming to offer their clients an even superior technical & commercial service, united their forces & skills in 2012 to start a new collaboration. This joint venture will allow ATOM, CHIESA & their group affiliates throughout the world the ability to offer their clients the most complete range of die cutting presses & systems for a wide variety of industrial markets.

Established in 1958, ATOM SpA – Vigevano Italy – has become the world’s leading manufacturer of die cutting presses & systems. With over 250,000 oil dynamic clicker presses in production today, the ATOM name has become a symbol of quality, reliability & technology in the cutting world.

Chiesa Artorige Srl has been manufacturing cutting presses in Vigevano, IT for over 50 years and is considered the market leader for industrial die cutting applications – particularly for the abrasive, gasket, foam & automotive markets. Chiesa pioneered automatic die cutting and developed the first belt fed diecutting press in the late 1980’s & patented the electrically driven (no hydraulics) CNC automatic cutting press in 2006.