Chiesa

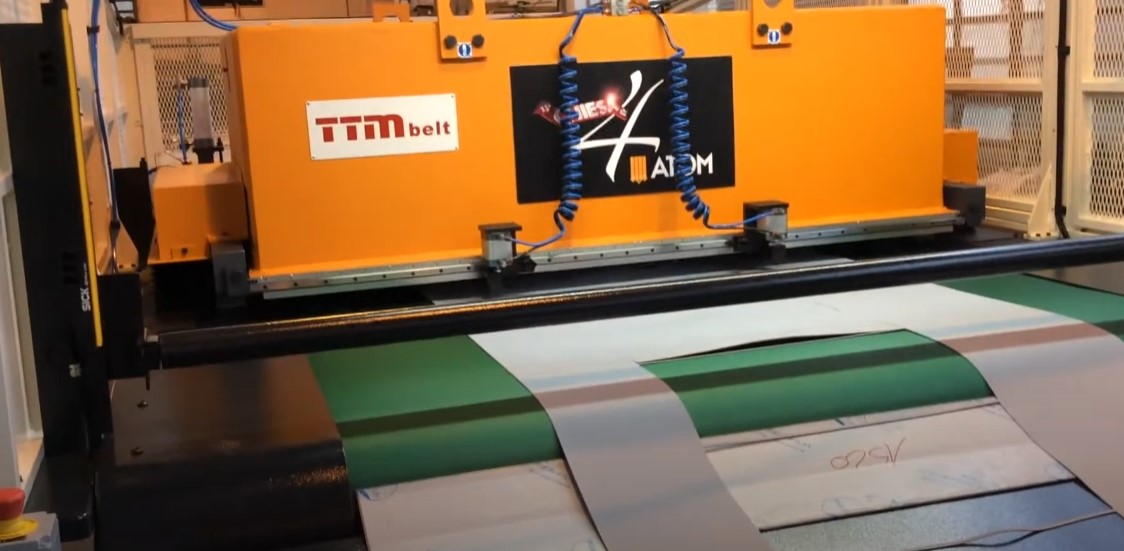

TTM Belt Series

The Chiesa Series Automatic Full Beam Die Cutting Systems equipped with “pinch & grab” feeding clamps and transport cutting belt are powerful, extremely precise & fast which allow for a fully automatic cutting cycle, with cutting speeds up to 23 strokes per minute on the entire width of the material.

The Chiesa TTM Belt Series Automatic Full Beam Presses are engineered with two hydraulic cylinders coupled with a synchronization bar – the bar includes a crank gear to synchronize the movement of the two hydraulic cylinders. This mechanical balancing system guarantees the maximum cutting force of the press and keeps the cutting base and upper platen parallel even under uneven loads. The Chiesa hydraulic press can execute its total force at any point in the down stroke.

The Chiesa Hydraulic Heated Cutting Presses have a maximum operating temperature of 500°F and are available with a variety of cutting powers, platen dimensions and feeding systems. Platen dimensions, cutting power, dwell time, heat specifications (top and bottom) along with the level of the control software are critical components to maximize users’ manufacturing processes. The heated platens are insulated to maintain uniform temperature, and the platen heaters are specially coated to improve heat transfer and ease of removal. Insert heaters provide efficient energy usage and rapid heat up and recovery times coupled with higher-temperature capabilities, with lower maintenance when compared with hot oil systems.

Points of Strength

- Robust reinforced structure with heavy duty weldments – Quality & Design Made in Italy

- Central self-lubricating system reduces maintenance & increases production

- Electrically controlled mechanical positive head stops via servo motors.

- Separate hydraulic unit with triple stage accumulator for ease of maintenance & increased production throughput.

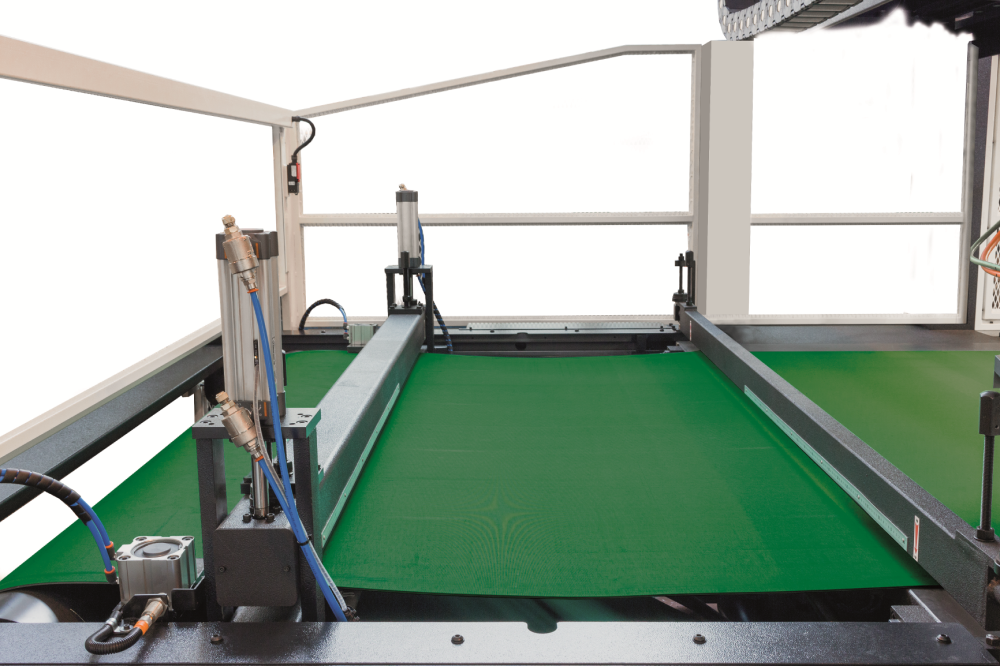

- Automatic pad shifting device increases the life of the cutting board & provides an even surface to accurately cut onto.

- Adjustable die rail supports with automatic height adjustment so cutting dies of different dimensions & thicknesses can be utilized.

- Motorized belt brush to keep cutting surface free from debris

- Variety of auxiliary material handling devices including single & multi-position roll carts with independent controls & automatic sheet loading devices.

- Vision system & sheet detection with camera & pertinent software.

- Advanced Safety Features – European CE Mark of Conformity

Other Video

Automatic Cutting-die machine with

Fixed head and number control

Pliers Power Supply

Specially designed for multi-layer materials, combined with the cutting belt it guarantees the most accurate advancement precision.

Touch Screen Computer

Number control designed to simplify all automation procedures and to fulfill all functions for setting, travel, cut, speed, feeding, advancement quotas etc... And to ensure at all times complete diagnostics of machine functions.

Hydraulic Tank

Separate from the machine, easily accessible.

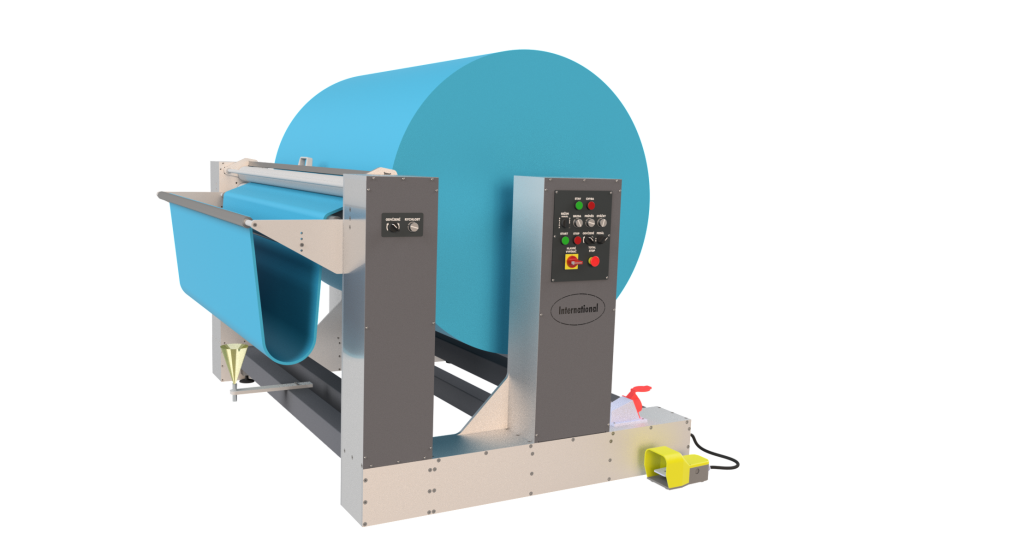

Material Handling Solutions

International Unwinders-Rewinders

PDF - 720 KB

The machine is equipped with:

Dancer: A sensor for monitoring material sag, controlling the drive shaft based on its data. Winding with sag allows for reduced stretching during material uptake

The machine is equipped with:

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Sensor: Monitors material sag, adjusting winding speed accordingly

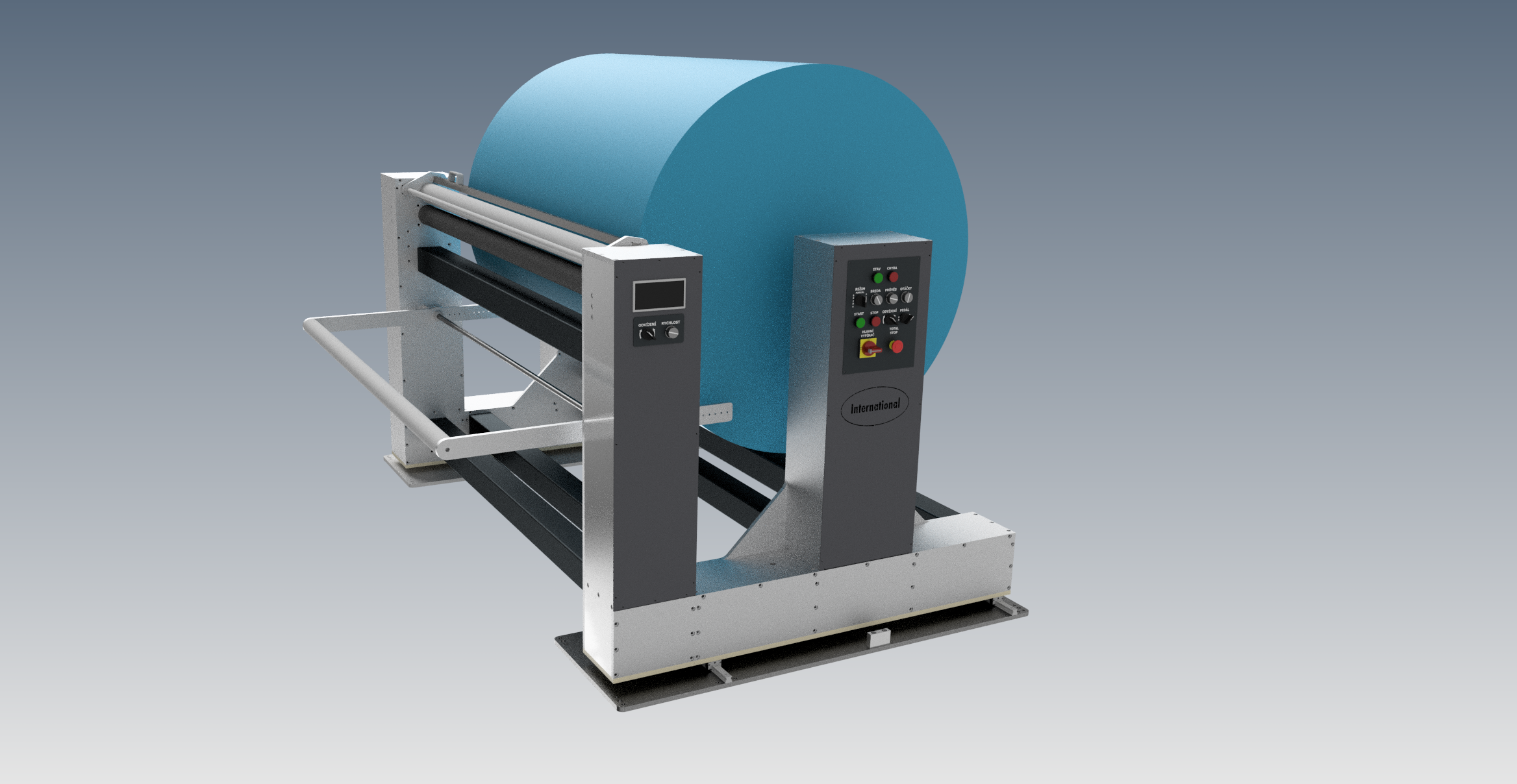

The machine is equipped with:

Dancer: A sensor for monitoring material sag, facilitating reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder.

Side Control: A device for aligning winding; it adjusts the position lightly if the material is unwound off-center.

The machine is equipped with:

Dancer: A sensor for monitoring material sag, optimizing drive shaft control for reduced stretching during material uptake.

Puller: Assists the drive during winding and creates tension between subsequent machines and the unwinder

The machine is equipped with:

Dancer: For sag monitoring and optimized drive puller, ensuring reduced material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: Ensures precise winding alignment, adjusting position if material is unwound off-center.

The machine is equipped with:

Dancer: For sag monitoring and optimized drive shaft control, minimizing material stretching during uptake.

Puller: Assists the drive during winding.

Side Control: For accurate winding alignment, making slight adjustments if material is unwound off-center

The machine is equipped with:

Loader: A device for enhanced material handling, automatically raised by the machine for improved efficiency.

Puller: Assists the drive during winding

The machine is equipped with:

Holder: A device for shaft retention, with a maximum capacity of 4 units.

Downloads

Download CHIESA

TTM Belt Series

PDF - 12.3 MB