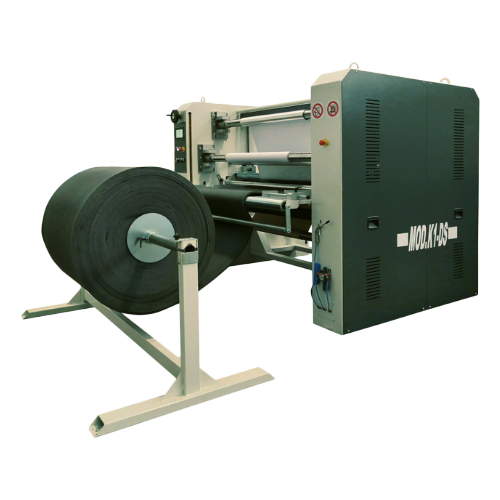

IMESA K1 DS

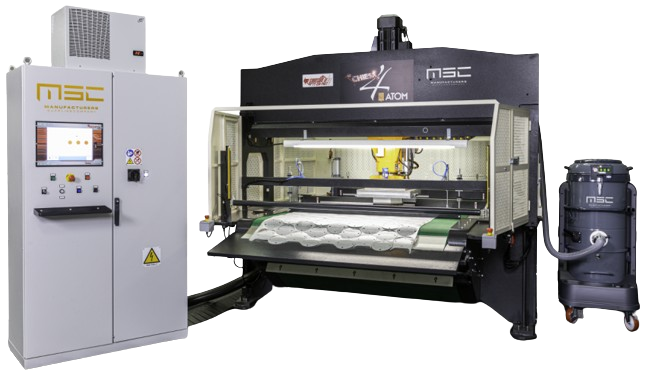

Double Sided Laminator

The IMESA K1 Easy Laminator is an economical entry level laminator for the lamination of heat-activated or cold bond adhesive to various foam materials, textiles, adhesive & non-adhesive tapes, rubber, cork and similar products.

The IMESA K1 DS Double Sided Laminator is cost effective laminating solution for the lamination of heat-activated or cold bond adhesive to both sides of the substrates including foam materials, textiles, adhesive & non-adhesive tapes, rubber, cork and similar products. This Foam Laminator is engineered to achieve consistent results with minimal set up time whilst adopting a versatile approach to current and future requirements all at a very competitive level of investment.

The K1 will laminate self-adhesive paper & films to foams and similar materials direct from the roll, either cold (pressure only) or with heating integrated into the calendaring nip rollers.

This machine is very simple to set and to operate with the following features incorporated as standard:

- Motorized material unwind, complete with 3” pneumatic expansion shaft – Maximum diameter of 1400mm

- Automatic alignment (Edge Guide) system controlled by photocell with a travel stroke of +/- 25mm

- Dancer roller for loop control

- Variable operating speeds from 0 – 20 meters per minute.

- Upper Winder-Rewinder for liner removal, tension electronically controlled, with 3” pneumatic expansion shaft.

- Upper unwind for adhesive film with mechanical brake & 3” expansion shaft.

- Lower unwind for adhesive film with mechanical brake & 3” expansion shaft.

- Entrance table with adjustable inclination to avoid the “curling” effect.

- Upper & lower motorized silicone covered calendar rollers complete with heating device with adjustable temperature up to 100° Celsius

- Variable calendar spacing from 2-100MM with mechanical visualization

- Upper & Lower rewind station with electronic clutch and 3” pneumatic expansion shafts

- Siemens HMI Touchscreen to check the machines operating functions.

- Optional entrance & exit tables for sheet lamination.

- Optional Scissor Cut or Pressure Cut Slitting Unit

- Optional Semi-Automatic Transversal Cross Cutting unit with motorized circular blade & pneumatic material locking device.

An option package allows sheet fed material to also be processed ensuring complete versatility.

For customers needing to process materials where an adhesive transfer film is required on just a single side, the model K1 Easy Laminator can be selected.

Downloads

Download IMESA K Series Laminators Brochure

PDF - 1.00 MB

Download Imesa K1 DS Foam Laminator Layout

PDF - 117 KB

- Description

- Technical Specifications

The IMESA K1 DS Double Sided Laminator is cost effective laminating solution for the lamination of heat-activated or cold bond adhesive to both sides of the substrates including foam materials, textiles, adhesive & non-adhesive tapes, rubber, cork and similar products. This Foam Laminator is engineered to achieve consistent results with minimal set up time whilst adopting a versatile approach to current and future requirements all at a very competitive level of investment.

The K1 will laminate self-adhesive paper & films to foams and similar materials direct from the roll, either cold (pressure only) or with heating integrated into the calendaring nip rollers.

This machine is very simple to set and to operate with the following features incorporated as standard:

- Motorized material unwind, complete with 3” pneumatic expansion shaft – Maximum diameter of 1400mm

- Automatic alignment (Edge Guide) system controlled by photocell with a travel stroke of +/- 25mm

- Dancer roller for loop control

- Variable operating speeds from 0 – 20 meters per minute.

- Upper Winder-Rewinder for liner removal, tension electronically controlled, with 3” pneumatic expansion shaft.

- Upper unwind for adhesive film with mechanical brake & 3” expansion shaft.

- Lower unwind for adhesive film with mechanical brake & 3” expansion shaft.

- Entrance table with adjustable inclination to avoid the “curling” effect.

- Upper & lower motorized silicone covered calendar rollers complete with heating device with adjustable temperature up to 100° Celsius

- Variable calendar spacing from 2-100MM with mechanical visualization

- Upper & Lower rewind station with electronic clutch and 3” pneumatic expansion shafts

- Siemens HMI Touchscreen to check the machines operating functions.

- Optional entrance & exit tables for sheet lamination.

- Optional Scissor Cut or Pressure Cut Slitting Unit

- Optional Semi-Automatic Transversal Cross Cutting unit with motorized circular blade & pneumatic material locking device.

An option package allows sheet fed material to also be processed ensuring complete versatility.

For customers needing to process materials where an adhesive transfer film is required on just a single side, the model K1 Easy Laminator can be selected.

Imesa Laminator Configurations for Acoustic & Thermal Insulated Panels, Interiors, Gaskets & Technical Components

- Automotive

- Aerospace

- Insulation

- Flooring/Roofing

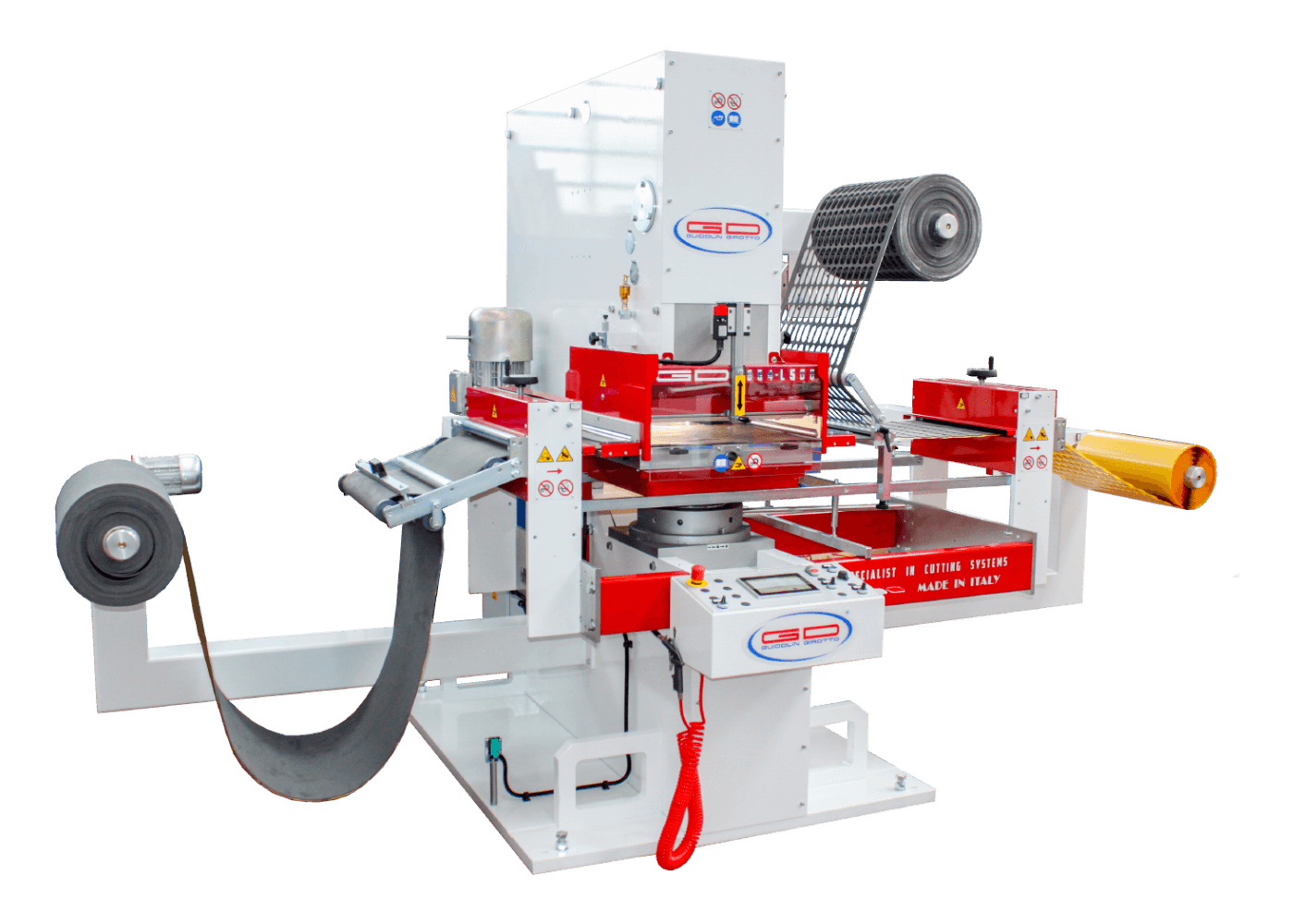

Imesa Model KK1 T LC TC F: Hot oil double side laminator, with slitting and continuous cross cutting unit and external rewinder. This machine can laminate material (foam, felt and similar) with thermal adhesive/foil and standard PSA. The lamination calendar is composed of an upper and lower fluoropolymer covered steel roller, with a thermal oil heating system, adjustable up to 445 F..

The longitudinal slitting system is specifically designed for thick foam materials up to 150mm in thickness. The system works with 360mm powered circular knives cutting on a squared nylon counterblade. The automatic transversal cross cutting device can sheet the material at different speeds and at different set lengths, “following” the material… the system has a “double trim” option, to get a (clean) cut on the first and the last edge of the sheets.

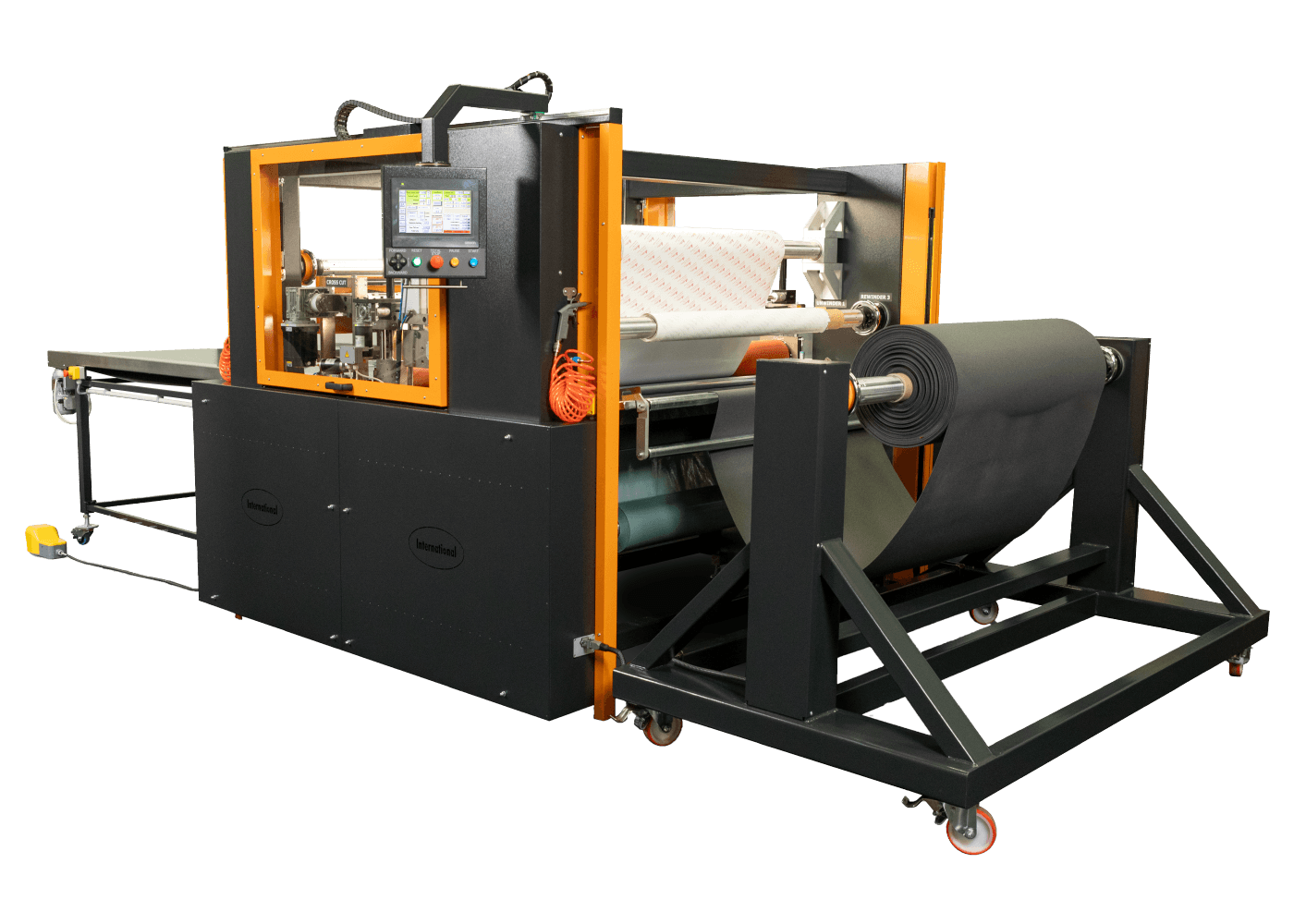

Imesa Model K1 DS TC Belt: Double side laminator with entrance feeding conveyor, transversal cross cutting unit and two exit rewinders. This laminator is suitable to laminate stretchy material (such as EPDM foams) in both rolls or sheets thanks to the entrance conveyor belt checked by a brushless motor with adjustable inclination to avoid the curling effect. When laminating sheets, the FTC sheet presence sensor detects the first edge of the sheet allowing the Laminator to transversally cut between the two sheets even when the top surface is laminated.

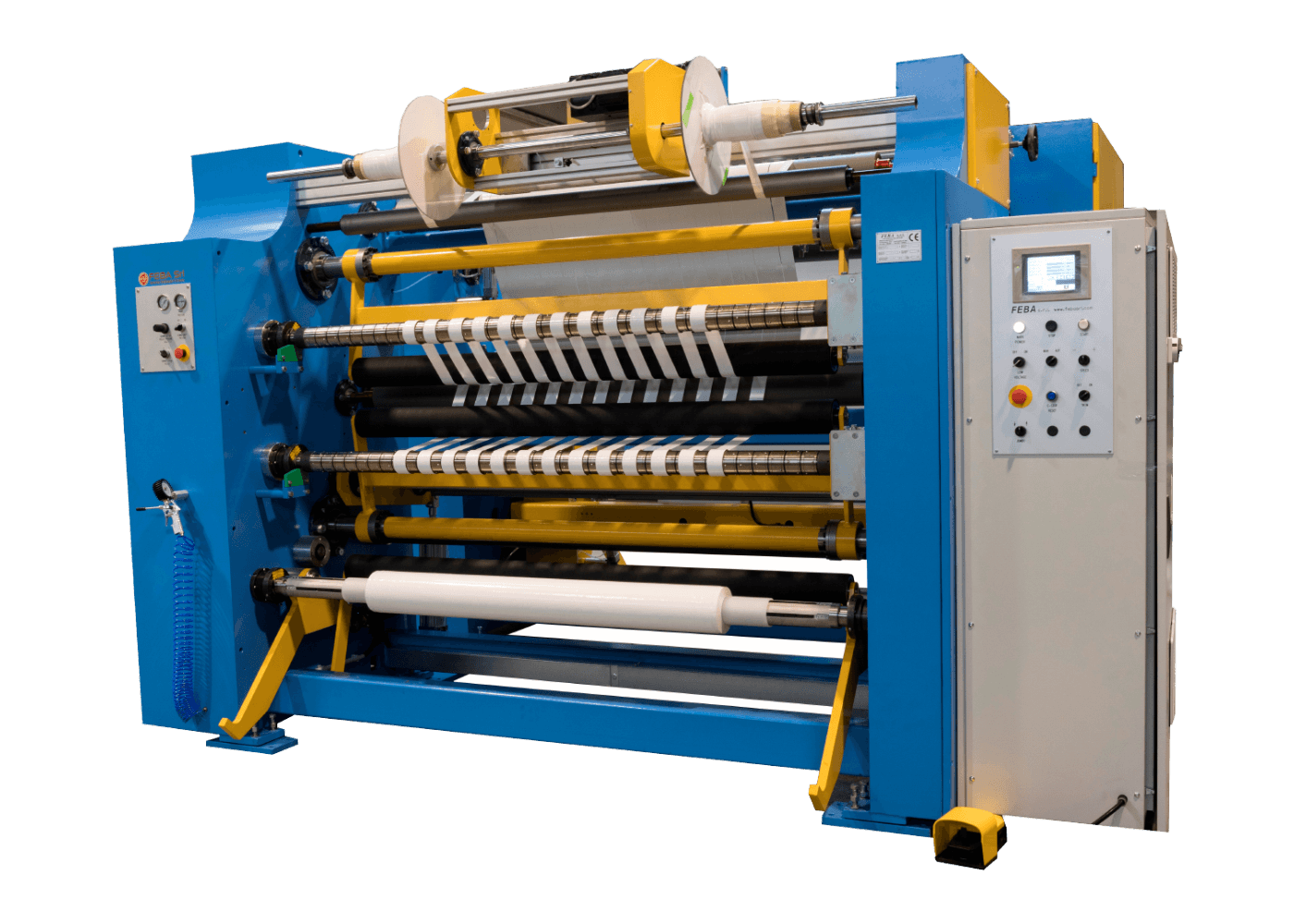

Imesa Model KK1 DS LC 2 REW: Double sided laminator equipped with a powered unwind, two large diameter calendars, with slitting and external double axis rewinder. This laminating system is ideal to laminate foam and sponge materials (even thick), due to the double calender and the large diameter of the nip rollers (250mm OD). After the slitting station we have a double option for the upper rewinder: |Rewinder| remove a liner from the final product (to rewind the roll without wrinkles), or |Unwinder| laminate the material with another liner or foil. The dual external rewinder can rewind two rolls at 1000mm or a single roll at 1500mm.

Imesa Model KK1 DS LC Pre-cut: Double sided laminator with powered unwind, slitting unit and two exit rewinders. The external unwind is equipped with an AC motor + inverter, dancer bar for loop control and an automatic web guide with +/- 50mm stroke. This laminator has a Pre-cut device capable of cutting the liner (and not the adhesive) and the ability to insert a “tabbing option” between liner and adhesive (similar to an overlap liner). The score cut slitting unit cuts with pressure on a powered steel countershaft, with a minimum slitting width of 25mm and maximum material thickness at 10mm.