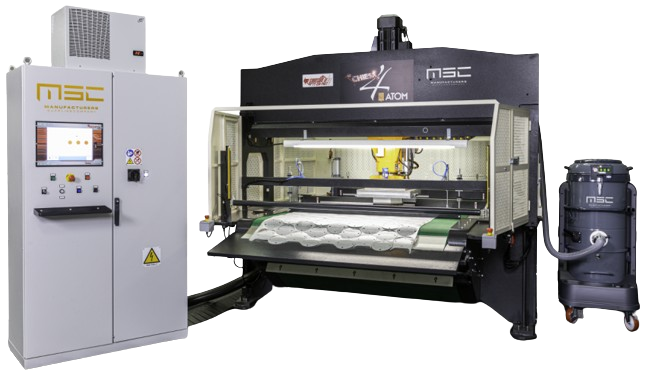

IMESA / ANTARES

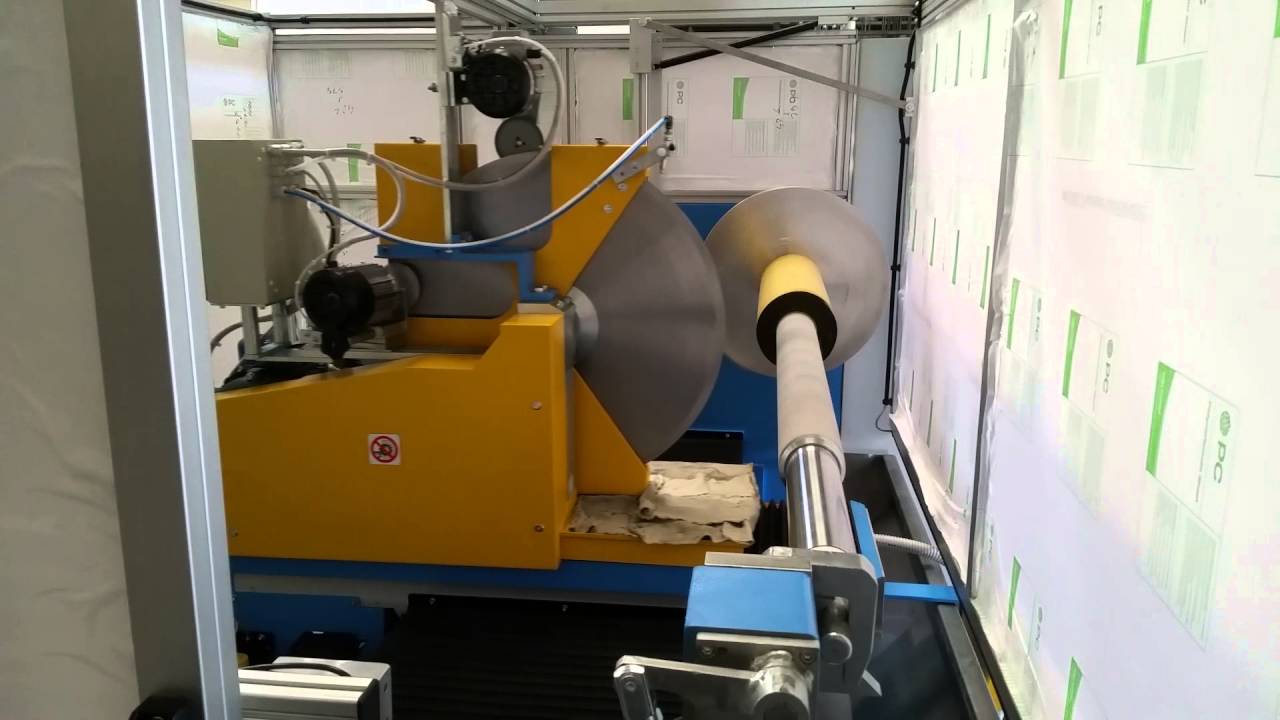

Multi-blade Slitters

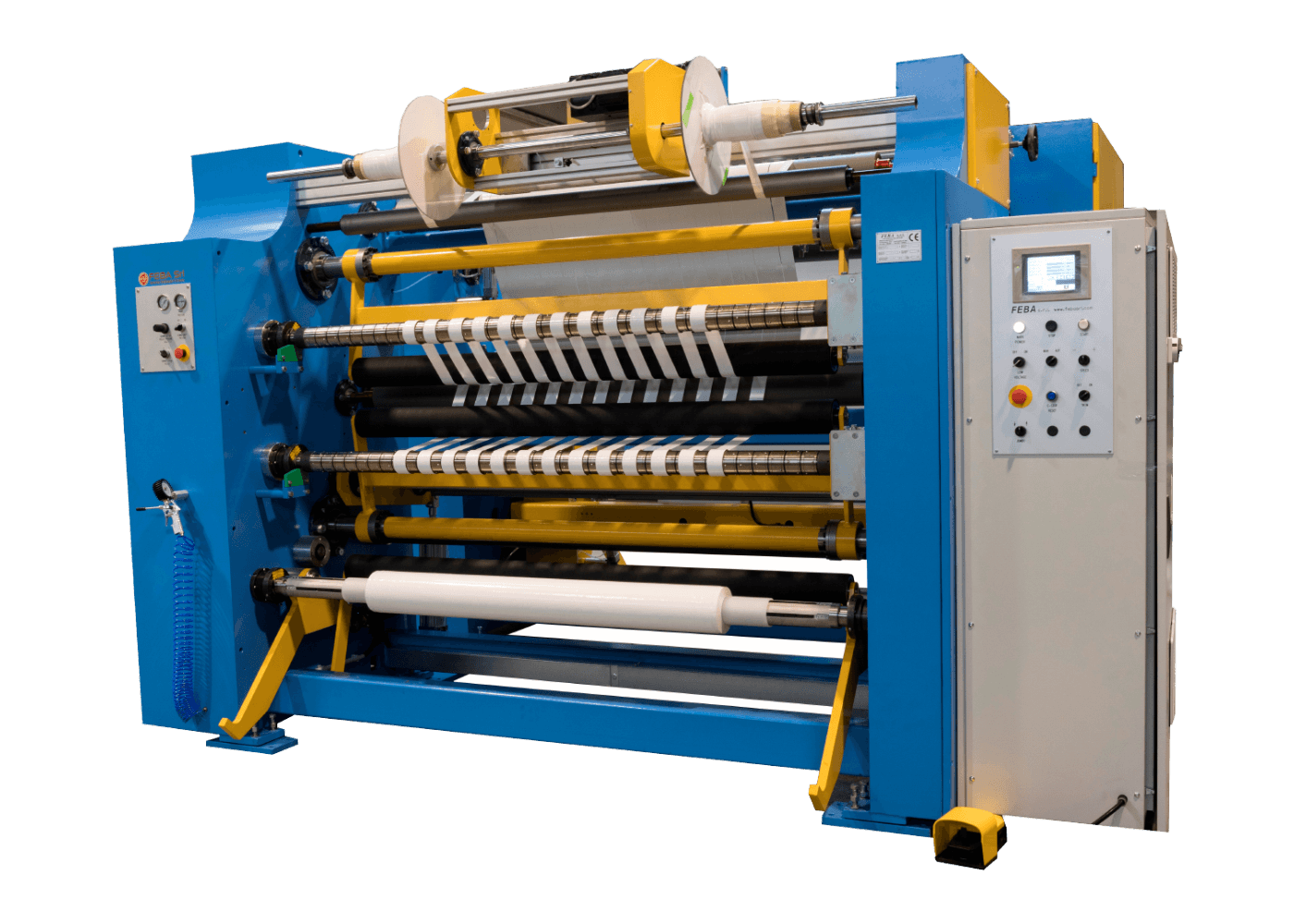

Present on the market since 1967, we are a leading company in cutting machines for strips from 150 to 2000 mm.

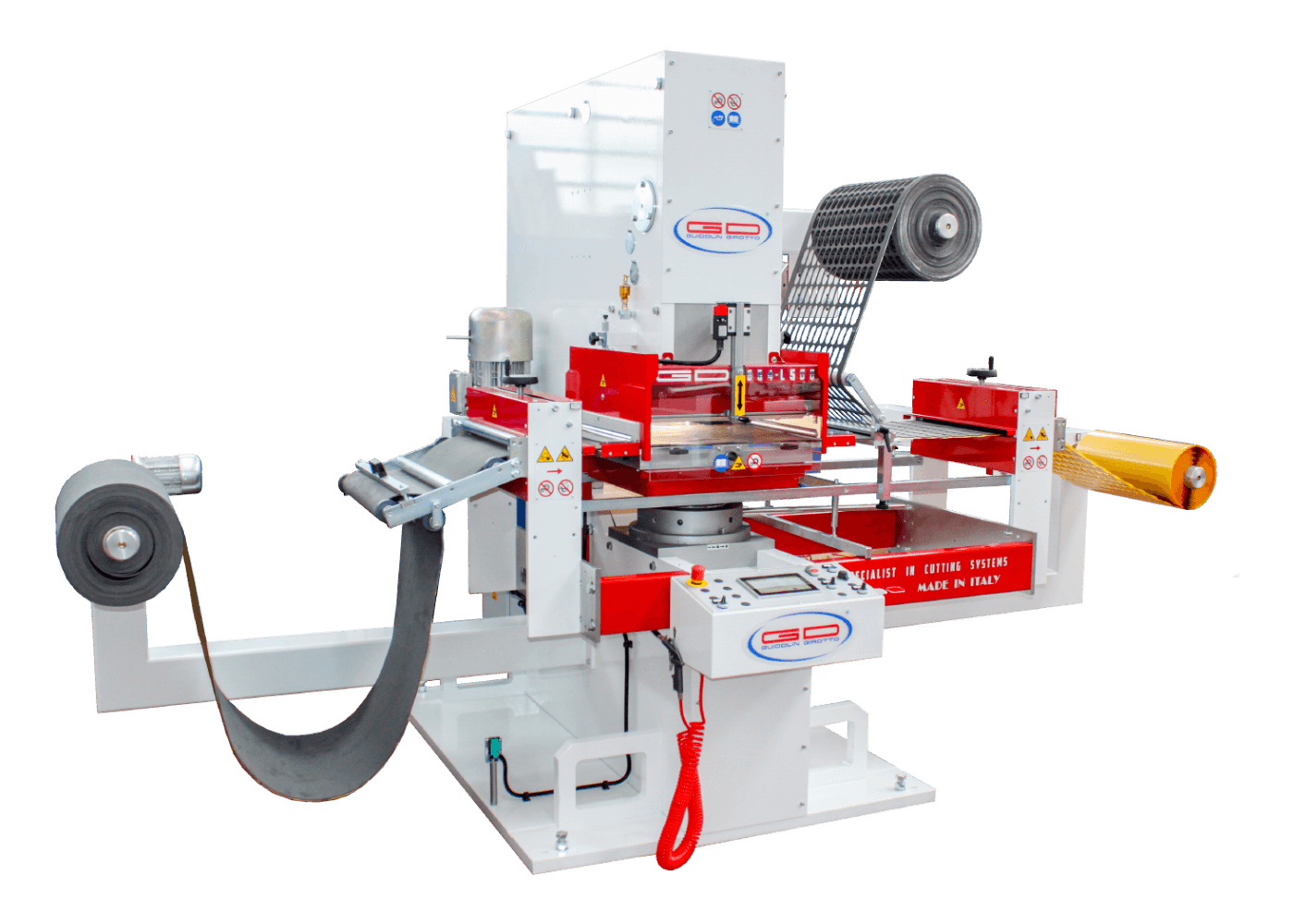

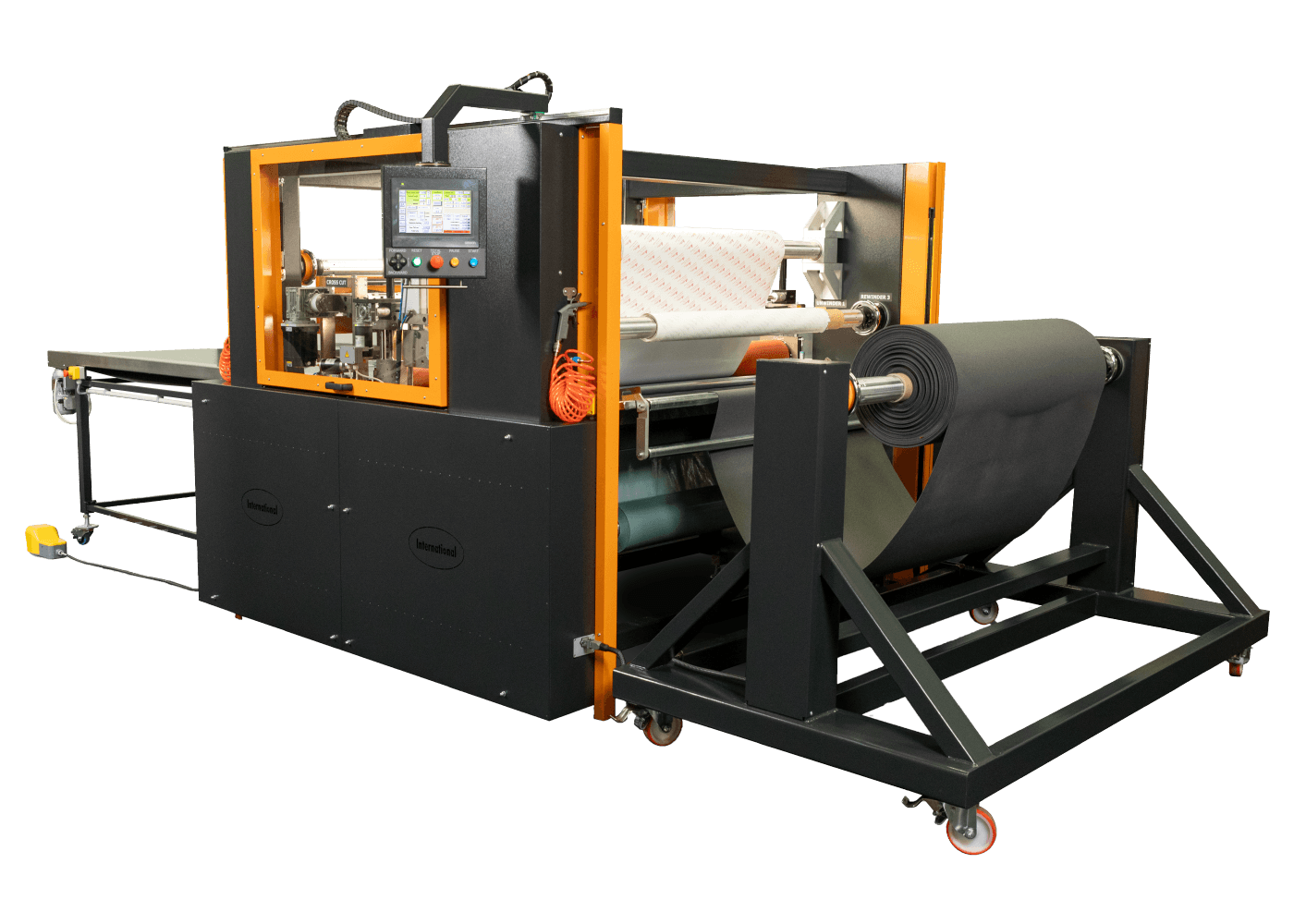

IMESA Srl, a 40 year old Italian company, engineers & manufactures a complete range of multi-blade slitters, slitters-sheeters & transversal guillotine cutting systems, with working widths from150mm to 3200mm, for companies working in several industries including; gaskets, heavy rubber, conveyor belting, calendared materials for pipe production, expanded materials, leather, transportation upholstery and similar fields.

Our machines are used in different processing sectors and in the mechanical sector of footwear and leather goods , where it is necessary to cut into strips materials such as: synthetics , leather , skin , rubber and other NON-ferrous or porcelain materials.

Our range, manufactured in compliance with CE regulations, consists of different models that meet your cutting requirements and guarantee the best working precision.

Their production includes fully automatic electronic lathe slitting systems (single & multi-shafted), slitters-rewinders, semi-automatic & fully automatic log winders, packaging machines, sawing machines for protection films & specialty laminating systems.

Excellent quality standards, technology, high slitting precision, versatility & custom solutions are distinctive features of the MESA machinery range which qualify them a world leader in the converting sectors