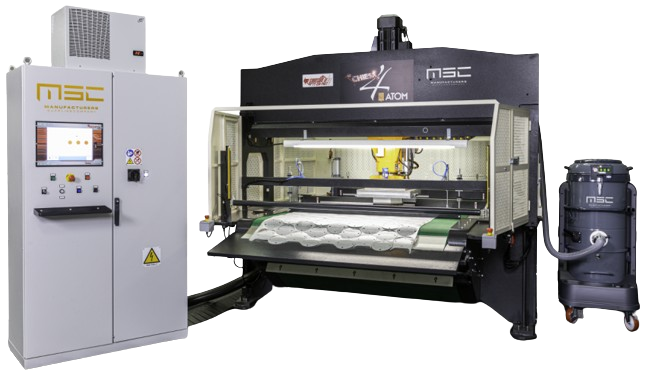

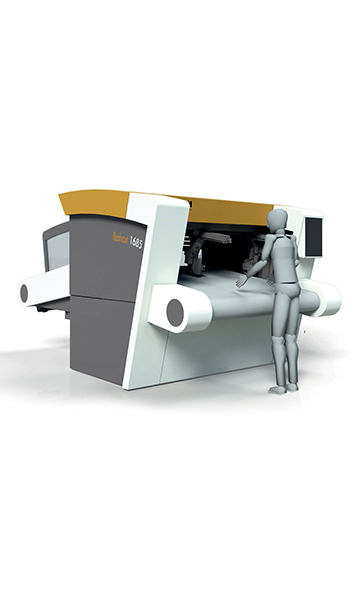

Perfect synthesis of an attractive design and technical/functioning features at the state-of-the-art, the cutting systems of the fashion series represent the new benchmark in leather goods and footwear production. Their two cutting heads, precision, speed, and reliability, joint to a highly ergonomic design and to an easy and intuitive software interface enable you to reach high production results and maximum output even in case of big patterns.

FASHION B Series

FASHION BP Series

FASHION ALL-IN-ONE Series

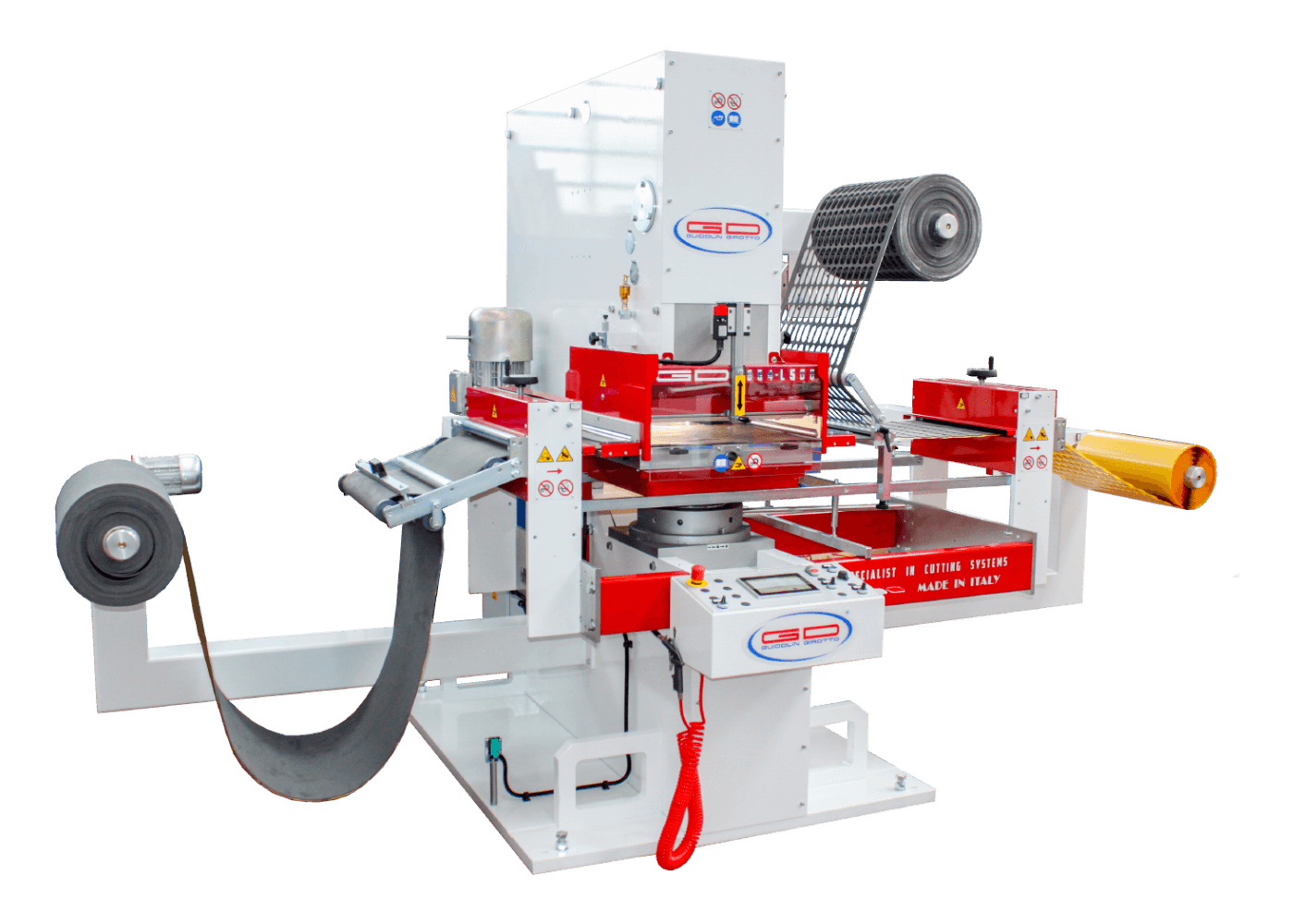

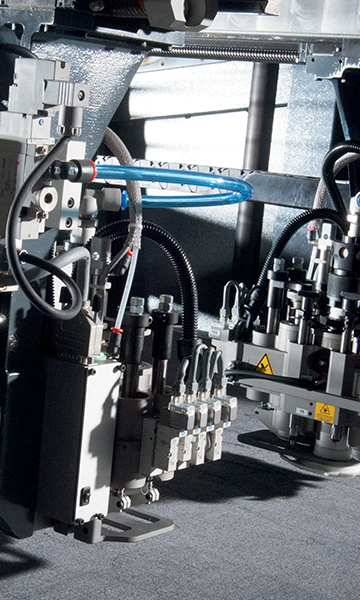

The new “FLEX” series represents the evolution of the previous architecture of great success with over 2500 units installed worldwide since 2002. The new structure boasts several improvements in technology (cutting head, tooling options, electronics) and software (interface program, CAD compatibility & options) together with the new compact design make them extremely flexible for a wide range of industrial applications.

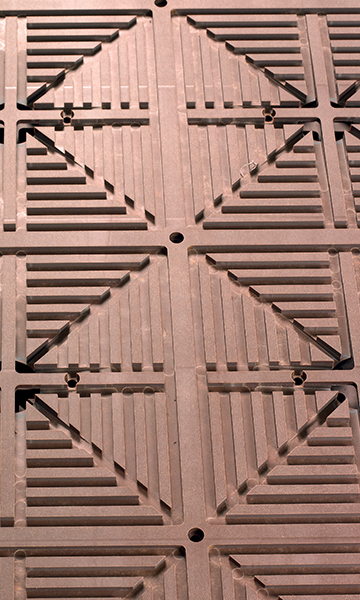

The solid steel rack and pinion system in place of a cogged belt increase the precision and operating speeds of the machine while the two pre-charged linear guide rails and enlarged beam adds to the robustness of the system. The new cutting surface with a higher degree of planarity coupled with the unique partitioned zoned vacuum system add even more suction power improving cut quality and overall accuracy.

With the option to add an overhead camera system for material contour recognition, projectors to visualize the cutting layout for assisted parts collection, the modular multi-tool cutting head and the powerful yet simple to use production control software make the FlashCut “FLEX” an efficient, versatile and powerful CNC digital knife cutting system.

+PLUS|Flashcut Fashion

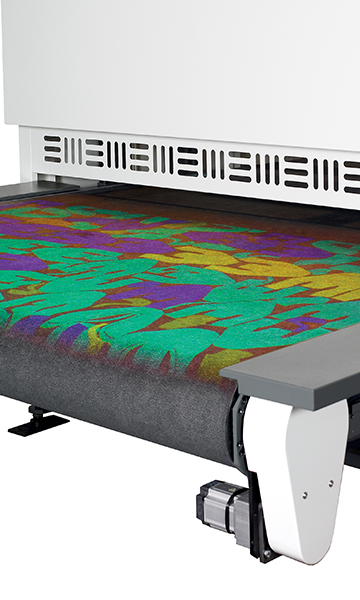

Partitioned Vacuum System

Powerful, partitioned and adjustable vacuum system. Best fixing during cutting and highest energy saving.

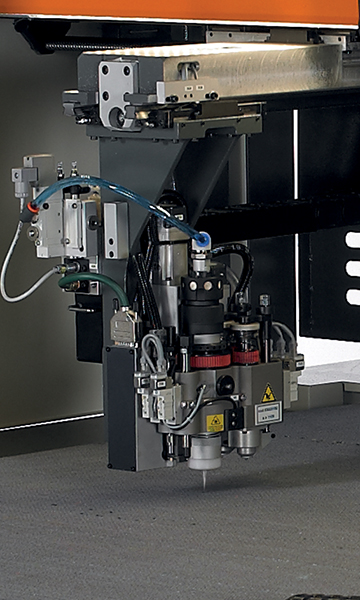

High Cutting Accuracy

The perfect parallelism between knife and working surface grants the highest cutting accuracy.

Performance and Reliability

Perfect quality and cutting speed. Accurate mechanic engineering. State-of-the-art electronics.

Optimized Nesting

Customized automatic nesting system. User friendly interface. Reduction of the process times and maximum material yield.

Design and Ergonomics

Original and ergonomic design combining easiness of use and style.

Picking Assistance

Speedy and easy picking of cut pieces thanks to the original software managing the back projectors, allowing to gather parts by size and color.

Acquisition Systems

To speed up the overall time for placing the shapes and optimize skilled manpower.

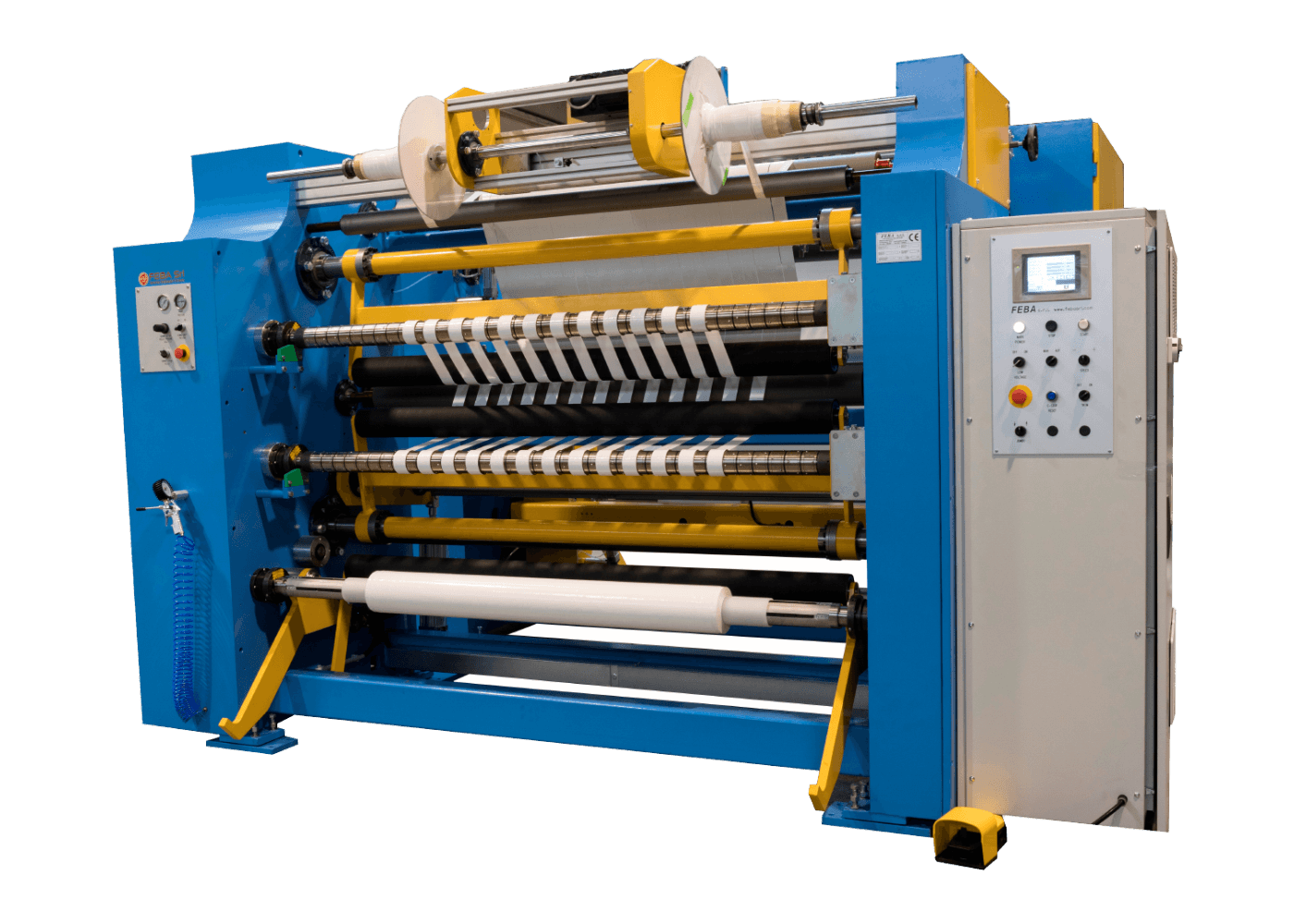

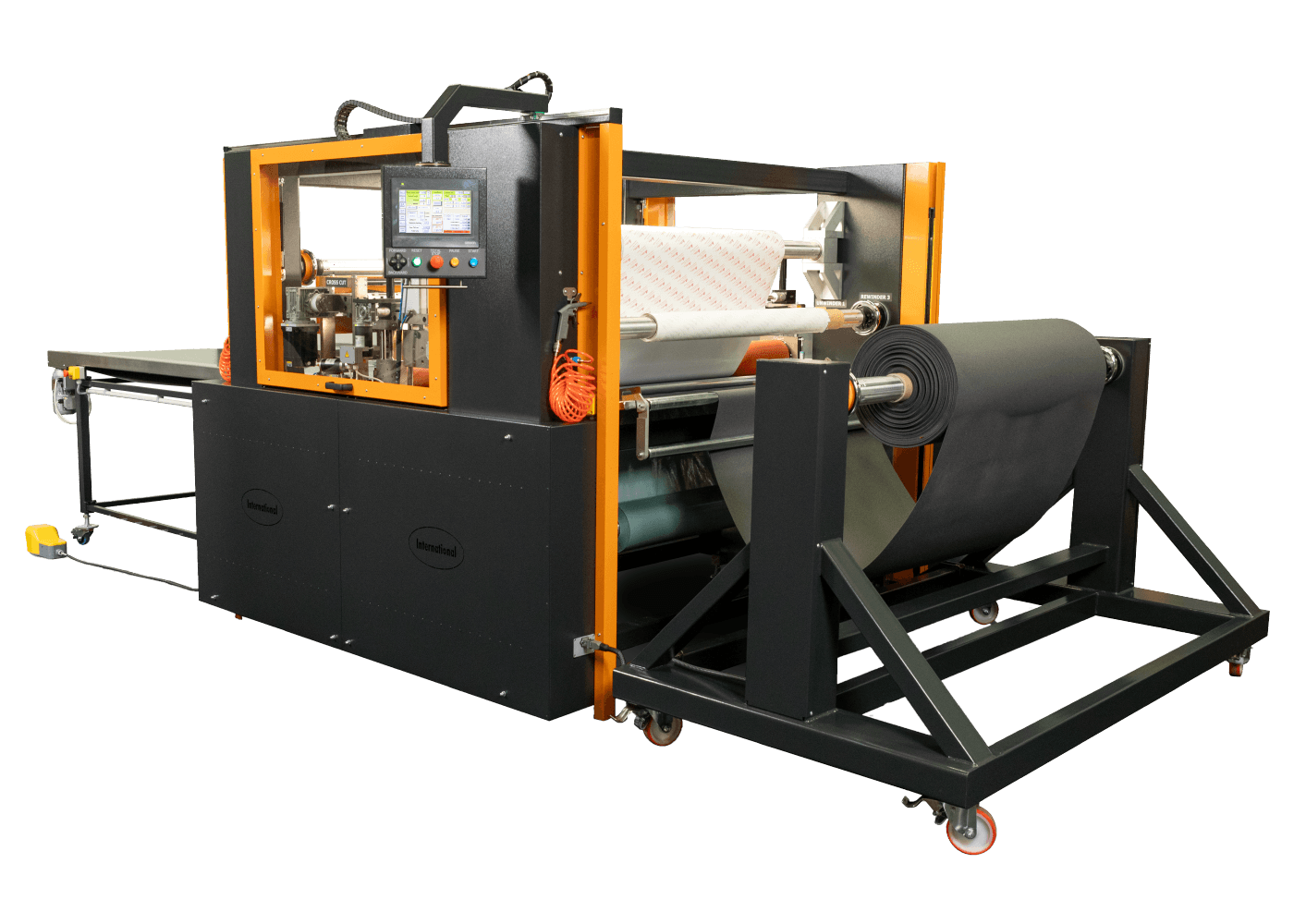

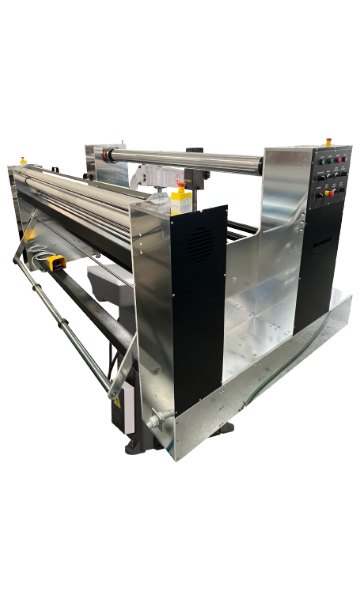

Modular Material

Handling Solutions

Standard & custom engineered material unwinds stands & winders, feeding and spreading machines, sheet-loaders, and in-line loading & off-loading tables.

Downloads

Download FASHION Series Brochure

PDF - 172 KB

Download FASHION ALL-IN-ONE Brochure

PDF - 81 KB